Resistance Welding Equipment

What is Resistance Welding Equipment?

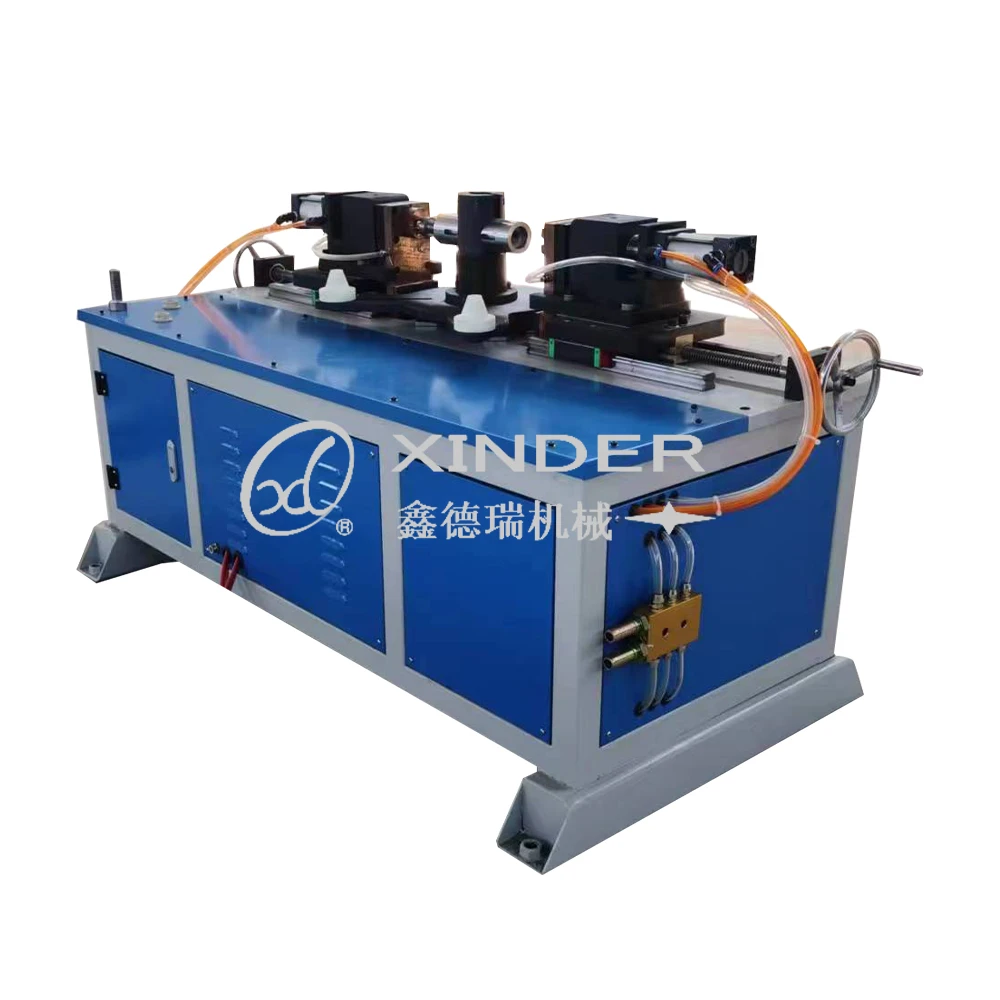

Resistance welding equipment is a type of industrial machinery used to join metal pieces by applying pressure and passing an electric current through the joint. The resistance to the electric current at the contact surfaces generates heat, which melts the metal and forms a strong, solid-state weld upon cooling. This process is commonly used for welding steel and other conductive metals.

The equipment typically includes a power supply, welding electrodes, a control system, and a mechanical framework. The electrodes clamp the metal parts together and conduct the current, while the control system manages the timing, pressure, and electrical parameters to ensure precise weld quality.

There are several types of resistance welding, such as spot welding, seam welding, projection welding, and flash welding. Each is suited to different applications, from automotive body panels to electronic components and household appliances.

Resistance welding is valued for its speed, repeatability, and clean operation, as it requires no filler materials or shielding gases. It's also energy-efficient and ideal for mass production due to its automation capabilities.

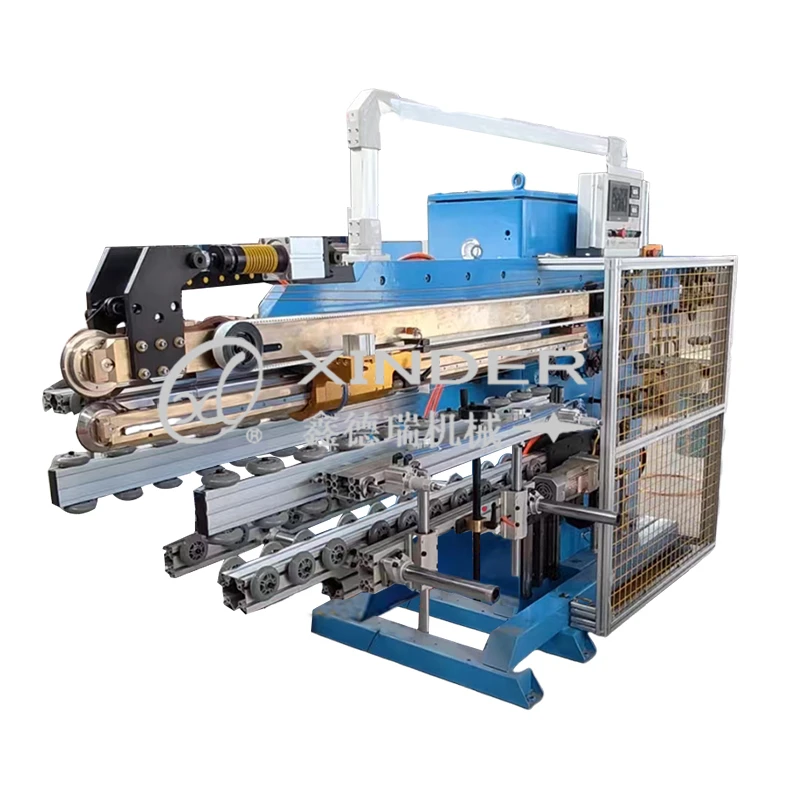

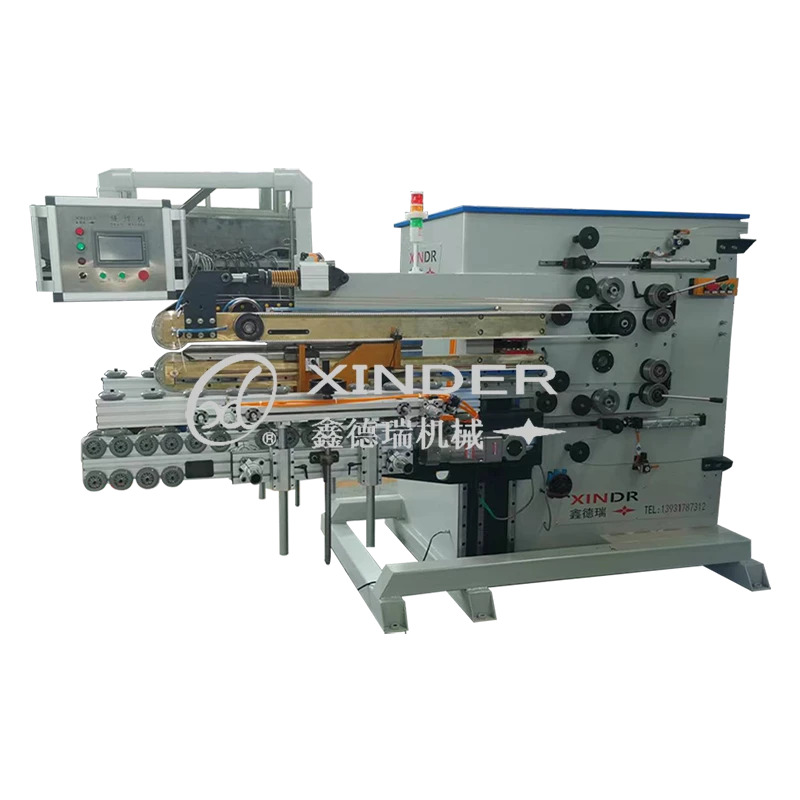

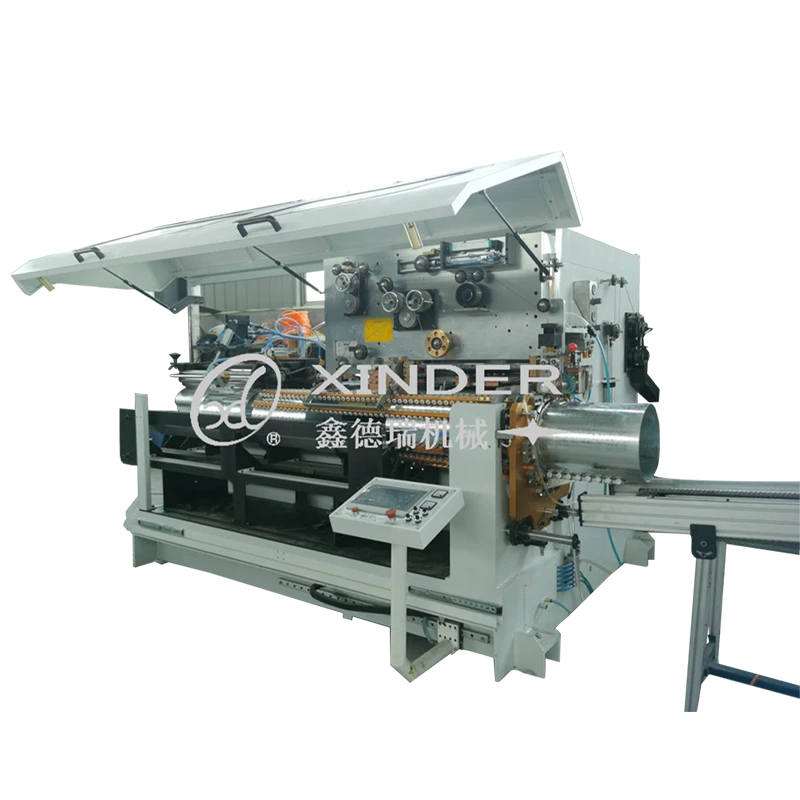

Spot Welding Machine for Sheet Metal

A spot welding machine for sheet metal is a specialized resistance welding device designed to join overlapping metal sheets at localized points. It works by clamping two or more sheets between copper alloy electrodes and passing a high electric current through the contact area. The resistance at the interface generates intense heat, forming a strong weld nugget in milliseconds without melting the surrounding material.

This machine is ideal for thin to medium-gauge sheet metal, commonly used in automotive bodywork, metal furniture, HVAC ducts, and appliance panels. It offers precise control over welding parameters such as current, pressure, and time, ensuring consistent weld quality with minimal distortion.

Modern spot welding machines often feature digital controls, pneumatic or servo-driven actuators, and safety interlocks for efficient and safe operation. Many models also support automation and robotic integration, making them suitable for high-speed production lines.

With low energy consumption, no need for filler material, and a clean, spark-free process, spot welding is one of the most cost-effective and eco-friendly methods for joining sheet metal components.