-

8613931787312

8613931787312 -

Botou Industrial Zone on the east side of National Highway 104, Botou City, Hebei Province

Botou Industrial Zone on the east side of National Highway 104, Botou City, Hebei Province

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- haitian_creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- scottish-gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

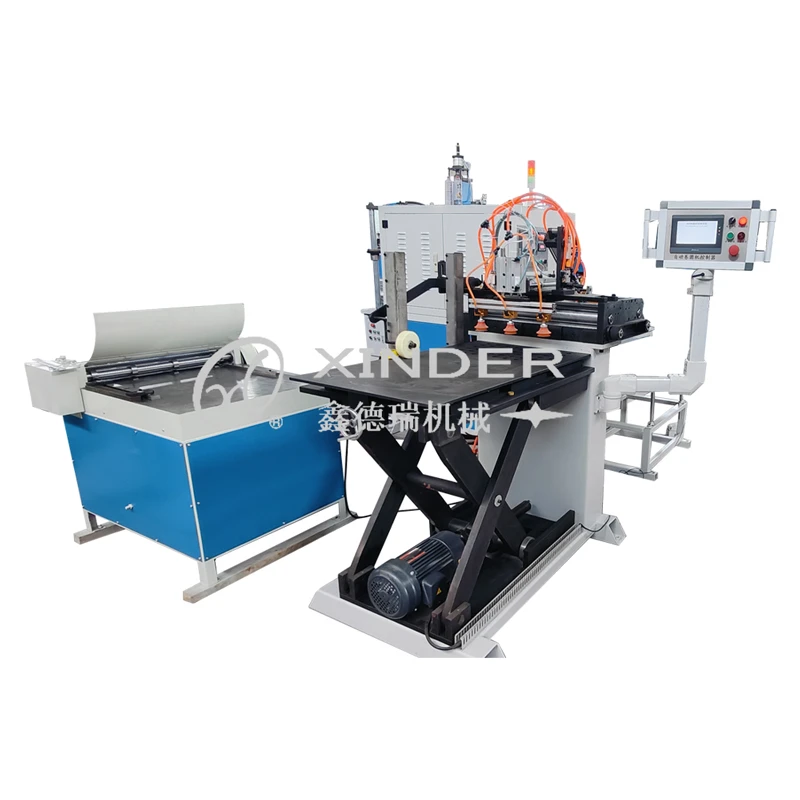

Featured Machine

ABOUT US

Xindrui Machinery Factory

Has 20+ Years.

Has 20+ Years.

Hebei Xindrui Machinery Manufacturing Co., Ltd. is located in Cangzhou City, Hebei Province. The Beijing Shanghai Railway, Expressway, and National Highways 105 and 106 run through the entire area, providing convenient transportation and superior geographical location.

The company's predecessor, Xindrui Machinery Factory (2000), has gone through more than 20 years. With the excellent industrial foundation in the northern surrounding areas, it has cultivated a non-standard equipment manufacturing team with professional research and development and advanced production capabilities.

-

2000 +Square Meters Factory Covers

-

100 +Market Distribution Worldwide

-

50 +Professional Technical Staff

-

20 +More Than 20 Years' Experience

Strength Display

Pipeline Display

Loading Picture

Friends' Group Photo

TURN YOUR TRAFFIC INTO LOYAL

CUSTOMERS AND RETURN VISITORS.

GET A QUOTE

CUSTOMERS AND RETURN VISITORS.

News & Events