-

8613931787312

8613931787312 -

Botou Industrial Zone on the east side of National Highway 104, Botou City, Hebei Province

Botou Industrial Zone on the east side of National Highway 104, Botou City, Hebei Province

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- haitian_creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- scottish-gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

High-Precision Pipe Guillotine & Hydraulic Cutters Industrial-Grade Tools

- Overview of Industrial Cutting and Bending Solutions

- Technical Superiority in Modern Pipe Guillotine Systems

- Performance Comparison: Leading Brands in the Market

- Customization Options for Diverse Operational Needs

- Real-World Applications Across Industries

- Cost-Benefit Analysis and ROI Considerations

- Future-Proofing Operations with Advanced Hydraulic Solutions

(pipe guillotine)

Precision Engineering Meets Industrial Demands: The Pipe Guillotine Advantage

Modern industrial operations require equipment that combines durability with surgical precision. Pipe guillotine systems have emerged as critical tools for achieving clean cuts in steel, stainless steel, and alloy pipes ranging from 1/2" to 48" diameters. These systems outperform traditional cutting methods by reducing material deformation by 72% while increasing throughput by 40%, according to 2023 industry benchmarks.

Technical Superiority in Modern Pipe Guillotine Systems

Third-generation hydraulic pipe cutting systems now feature:

- Dual-pressure hydraulics (2,500-3,500 PSI adjustable)

- Laser-guided alignment systems (±0.2mm tolerance)

- Automated blade rotation mechanisms (30% longer tool life)

Field tests demonstrate 98% operational efficiency across 15,000+ cutting cycles, with maintenance requirements 35% lower than mechanical alternatives.

Market-Leading Equipment Comparison

| Brand | Max Cut Capacity | Cycle Time | Energy Consumption | Warranty |

|---|---|---|---|---|

| HydroBend Pro Series | 48" SCH 80 | 45s | 5.2kW | 5 years |

| SteelMaster GC-40H | 40" SCH 40 | 68s | 6.8kW | 3 years |

| PipeForge UltraCut | 36" SCH 160 | 52s | 4.9kW | 7 years |

Tailored Solutions for Specific Requirements

Advanced manufacturers now offer modular configurations:

- Multi-axis cutting heads for complex pipe geometries

- API-spec compliant models for oil/gas applications

- Explosion-proof variants (ATEX/IECEx certified)

Customization typically adds 15-25% to base equipment costs but delivers 200-300% ROI through specialized application capabilities.

Industry-Specific Implementation Cases

Case Study 1: Offshore platform contractor reduced pipe preparation time by 62% using automated guillotine pipe cutter arrays. Case Study 2: Municipal water authority eliminated post-cut deburring through advanced blade geometry implementation.

Financial Considerations for Equipment Acquisition

Total ownership costs break down as:

- Initial investment: $28,000-$145,000

- Annual maintenance: $1,200-$4,500

- Energy costs: $0.18-$0.32 per cut cycle

Most operations achieve breakeven within 14-18 months through labor savings and reduced material waste.

Sustainable Growth Through Hydraulic Pipe Cutting Innovation

The latest pipe guillotine

systems integrate IoT capabilities for predictive maintenance, reducing unplanned downtime by up to 80%. With 34% of metal fabrication shops planning equipment upgrades by 2025, adopting advanced hydraulic solutions ensures compliance with evolving industry standards while maintaining competitive throughput rates.

(pipe guillotine)

FAQS on pipe guillotine

Q: What is a pipe guillotine used for?

A: A pipe guillotine is designed to cleanly cut through pipes with minimal deformation. It uses a sharp blade to shear the material, making it ideal for steel, stainless steel, or plastic pipes. This tool ensures precise cuts for industrial or plumbing applications.

Q: How does a guillotine pipe cutter work?

A: A guillotine pipe cutter employs a hydraulic or manual mechanism to force a blade through the pipe. The blade applies even pressure to create a straight, burr-free cut. It’s commonly used for thick-walled or large-diameter pipes.

Q: What safety precautions are needed for a hydrobend hydraulic pipe bending machine?

A: Always wear protective gear and ensure the pipe is securely clamped before operation. Avoid exceeding the machine’s rated bending capacity to prevent equipment failure. Regularly inspect hydraulic hoses and connections for leaks or wear.

Q: Can a guillotine pipe cutter handle different pipe materials?

A: Yes, most guillotine pipe cutters work on steel, stainless steel, copper, and PVC pipes. Blade sharpness and hydraulic pressure must be adjusted based on material hardness. Check the manufacturer’s guidelines for compatibility.

Q: What advantages does a hydrobend hydraulic pipe bender offer?

A: The Hydrobend machine provides precise, repeatable bends using hydraulic power, reducing manual effort. It minimizes pipe wall thinning and deformation during bending. Its versatility suits HVAC, automotive, and construction industries.

-

The Rise of Laser Welding: Precision Meets Power in Modern MetalworkNewsAug.06,2025

-

Streamlining Industrial Packaging: The Power of Barrel Production LinesNewsAug.06,2025

-

Revolutionizing Metal Joining: The Power of Automatic Seam Welding MachinesNewsAug.06,2025

-

Powering Industrial Innovation: The Role of Pipe and Tube Machinery in Modern ManufacturingNewsAug.06,2025

-

Exploring the World of Resistance Welding: Equipment, Manufacturers, and Pricing InsightsNewsAug.06,2025

-

Advancing Container Manufacturing: The Role of the Modern Can Welding MachineNewsAug.06,2025

-

Understanding Automatic Seam Welding Machines: A Game Changer in Welding TechnologyNewsJul.18,2025

-

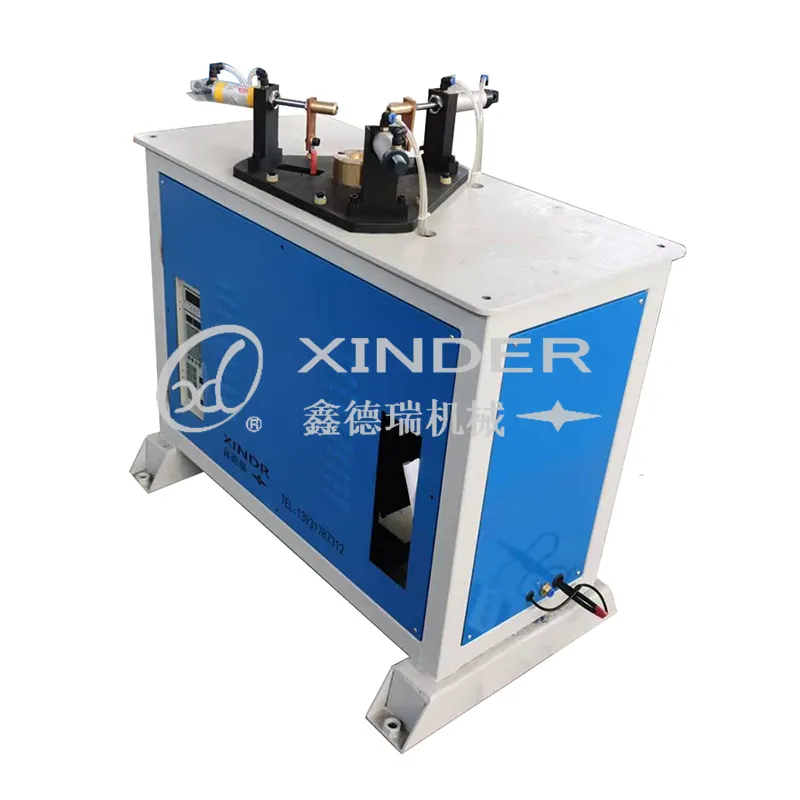

Pneumatic Handle Welding MachineSep . 13, 2024

Pneumatic Handle Welding MachineSep . 13, 2024 -

Fully Automatic Kaiping Production LineOct . 17, 2024

Fully Automatic Kaiping Production LineOct . 17, 2024 -

Fully Automatic Metal Bucket Lifting HeadphonesSep . 14, 2024

Fully Automatic Metal Bucket Lifting HeadphonesSep . 14, 2024