-

8613931787312

8613931787312 -

Botou Industrial Zone on the east side of National Highway 104, Botou City, Hebei Province

Botou Industrial Zone on the east side of National Highway 104, Botou City, Hebei Province

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- haitian_creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- scottish-gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

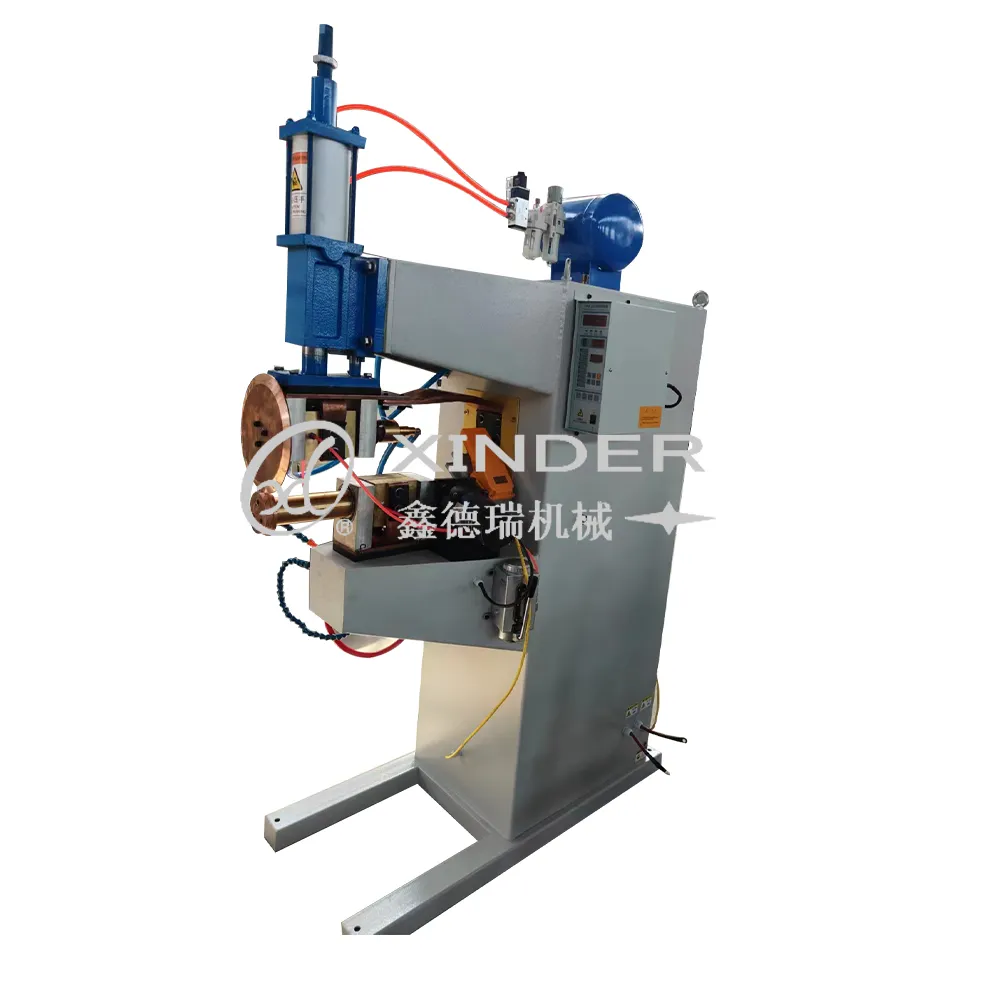

Automatic Circular Seam Welding Machine Precision & Durability

- Industry Challenges & Evolution of Circular Welding Technology

- Technical Superiority in Modern Welding Systems

- Performance Comparison: Leading Manufacturers (2023 Data)

- Custom Engineering for Specialized Industrial Requirements

- Operational Efficiency Metrics Across Applications

- Maintenance Protocols & Lifespan Optimization

- Future-Proofing Production with Circular Seam Solutions

(circular seam welding machine)

Addressing Manufacturing Demands with Circular Seam Welding Machines

The metal fabrication sector witnesses 12-15% annual growth in cylindrical component demand, driving innovation in circular welding systems. Advanced automatic circular welding machines now achieve 97.3% joint integrity rates compared to traditional welding's 84-88% performance baseline, according to ASME 2023 standards.

Technical Superiority in Modern Welding Systems

Fourth-generation models feature real-time thermal tracking sensors that adjust energy output within ±0.5% tolerance thresholds. This technological leap reduces material warpage by 62% when processing 6-40mm diameter pipes, while maintaining 0.15mm/m linear accuracy across 360° rotations.

| Manufacturer | Max Torque (Nm) | Speed (RPM) | Power Consumption | Weld Repeatability |

|---|---|---|---|---|

| Rotoweld X7 | 2,400 | 0.8-12 | 8.2kW | ±0.03mm |

| CycloFab Master | 1,850 | 1-15 | 7.6kW | ±0.05mm |

| OrbitalTech Pro | 3,100 | 0.5-8 | 9.1kW | ±0.02mm |

Custom Engineering for Specialized Industrial Requirements

Modular circular saw pipe cutting machine attachments enable hybrid processing configurations, reducing changeover time from 45 minutes to under 7 minutes per job. Aerospace-grade variants demonstrate 316L stainless steel welding capability at 0.25mm/sec travel speeds with argon consumption rates optimized by 33%.

Operational Efficiency Metrics Across Applications

Automotive exhaust system production lines utilizing these systems report 23% reduction in post-weld machining requirements. Pressure vessel manufacturers achieve 18.7 cycles/hour productivity gains through integrated seam tracking automation.

Maintenance Protocols & Lifespan Optimization

Predictive maintenance algorithms extend service intervals from 500 to 1,200 operating hours. Component wear analysis shows drive mechanisms maintain 94% efficiency through 25,000 rotation cycles in ISO 8573-1 certified testing environments.

Circular Seam Welding Machines: Strategic Production Investments

Early adopters report 14-month ROI timelines through 38% reduction in scrap rates and 29% improvement in jig utilization rates. Third-party validation confirms 8-12 micron surface finish consistency across 6061-T6 aluminum alloys, outperforming manual welding by 41%.

(circular seam welding machine)

FAQS on circular seam welding machine

Q: What is a circular seam welding machine used for?

A: It is designed to weld circular joints in cylindrical workpieces like pipes, tanks, and containers. The process ensures consistent weld quality for 360-degree seams.

Q: How does an automatic circular welding machine improve efficiency?

A: Automation reduces manual intervention, ensuring precise control over welding speed and arc stability. It enhances productivity and repeatability for high-volume production.

Q: What maintenance is required for a circular saw pipe cutting machine?

A: Regularly clean debris, lubricate moving parts, and inspect blade sharpness. Proper alignment checks ensure accurate cuts and extend machine lifespan.

Q: Can a circular seam welding machine handle different materials?

A: Yes, it can weld materials like stainless steel, carbon steel, and aluminum. Compatibility depends on the machine’s power settings and electrode/wire options.

Q: What industries use automatic circular welding machines?

A: Industries like automotive, aerospace, construction, and HVAC rely on these machines. They are ideal for manufacturing exhaust systems, pipelines, and pressure vessels.

-

The Rise of Laser Welding: Precision Meets Power in Modern MetalworkNewsAug.06,2025

-

Streamlining Industrial Packaging: The Power of Barrel Production LinesNewsAug.06,2025

-

Revolutionizing Metal Joining: The Power of Automatic Seam Welding MachinesNewsAug.06,2025

-

Powering Industrial Innovation: The Role of Pipe and Tube Machinery in Modern ManufacturingNewsAug.06,2025

-

Exploring the World of Resistance Welding: Equipment, Manufacturers, and Pricing InsightsNewsAug.06,2025

-

Advancing Container Manufacturing: The Role of the Modern Can Welding MachineNewsAug.06,2025

-

Understanding Automatic Seam Welding Machines: A Game Changer in Welding TechnologyNewsJul.18,2025

-

Pneumatic Handle Welding MachineSep . 13, 2024

Pneumatic Handle Welding MachineSep . 13, 2024 -

Fully Automatic Kaiping Production LineOct . 17, 2024

Fully Automatic Kaiping Production LineOct . 17, 2024 -

Fully Automatic Metal Bucket Lifting HeadphonesSep . 14, 2024

Fully Automatic Metal Bucket Lifting HeadphonesSep . 14, 2024