-

8613931787312

8613931787312 -

Botou Industrial Zone on the east side of National Highway 104, Botou City, Hebei Province

Botou Industrial Zone on the east side of National Highway 104, Botou City, Hebei Province

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- haitian_creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- scottish-gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

феб . 06, 2025 02:21

Back to list

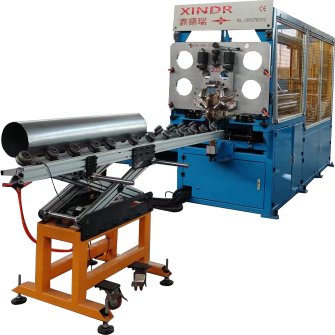

laser pipe cutting machine

Navigating through the industrial landscape, one cannot help but notice the rise in demand for precision-cutting solutions. At the core of this transformation is the laser pipe cutting machine, a marvel of engineering that stands at the intersection of technology and craftsmanship. This article sheds light on the profound attributes of such machines, ensuring your business not only meets industry standards but also achieves unmatched productivity and efficiency.

Trustworthiness is paramount when considering any investment in machinery, particularly those that form the backbone of production lines. Laser pipe cutting machines boast a reputation built on reliability and longevity. Engineered with state-of-the-art components and sophisticated software, these machines often feature intuitive interfaces that empower operators with control and customizability, reducing the margin for error and enhancing the overall operation’s efficiency. Moreover, manufacturers of these cutting-edge machines frequently provide comprehensive support and maintenance services, which are crucial in fostering trust and ensuring long-term operability. Real-world experience with laser pipe cutting machines often reveals a significant return on investment, thanks to reduced labor costs and increased throughput. By automating the cutting process, businesses can reallocate their human resources to other areas that require creativity and critical thinking, rather than repetitive manual labor. This shift not only boosts productivity but also results in cost savings, manifesting in healthier profit margins. A hallmark of these machines is their contribution to sustainable manufacturing practices. The precision of laser technology minimizes the generation of scrap material – a significant factor when considering the environmental impact of industrial operations. Additionally, many of these machines are designed to be energy-efficient, aligning with the global shift towards greener manufacturing technologies. This focus on sustainability helps businesses not only reduce their carbon footprint but also appeal to environmentally conscious consumers and stakeholders. In conclusion, a laser pipe cutting machine is more than just an industrial tool; it is a vital asset that embodies precision, versatility, and reliability. Businesses leveraging this technology are well-positioned to not only enhance their production capabilities but also maintain a sustainable and efficient operation. This aligns with the broader industry trend towards innovative, environmentally friendly, and future-proof manufacturing solutions. As such, investing in these machines is a strategic decision that reinforces a company's commitment to quality and excellence, ensuring a robust presence in today’s competitive market landscape.

Trustworthiness is paramount when considering any investment in machinery, particularly those that form the backbone of production lines. Laser pipe cutting machines boast a reputation built on reliability and longevity. Engineered with state-of-the-art components and sophisticated software, these machines often feature intuitive interfaces that empower operators with control and customizability, reducing the margin for error and enhancing the overall operation’s efficiency. Moreover, manufacturers of these cutting-edge machines frequently provide comprehensive support and maintenance services, which are crucial in fostering trust and ensuring long-term operability. Real-world experience with laser pipe cutting machines often reveals a significant return on investment, thanks to reduced labor costs and increased throughput. By automating the cutting process, businesses can reallocate their human resources to other areas that require creativity and critical thinking, rather than repetitive manual labor. This shift not only boosts productivity but also results in cost savings, manifesting in healthier profit margins. A hallmark of these machines is their contribution to sustainable manufacturing practices. The precision of laser technology minimizes the generation of scrap material – a significant factor when considering the environmental impact of industrial operations. Additionally, many of these machines are designed to be energy-efficient, aligning with the global shift towards greener manufacturing technologies. This focus on sustainability helps businesses not only reduce their carbon footprint but also appeal to environmentally conscious consumers and stakeholders. In conclusion, a laser pipe cutting machine is more than just an industrial tool; it is a vital asset that embodies precision, versatility, and reliability. Businesses leveraging this technology are well-positioned to not only enhance their production capabilities but also maintain a sustainable and efficient operation. This aligns with the broader industry trend towards innovative, environmentally friendly, and future-proof manufacturing solutions. As such, investing in these machines is a strategic decision that reinforces a company's commitment to quality and excellence, ensuring a robust presence in today’s competitive market landscape.

Next:

Latest News

-

The Rise of Laser Welding: Precision Meets Power in Modern MetalworkNewsAug.06,2025

-

Streamlining Industrial Packaging: The Power of Barrel Production LinesNewsAug.06,2025

-

Revolutionizing Metal Joining: The Power of Automatic Seam Welding MachinesNewsAug.06,2025

-

Powering Industrial Innovation: The Role of Pipe and Tube Machinery in Modern ManufacturingNewsAug.06,2025

-

Exploring the World of Resistance Welding: Equipment, Manufacturers, and Pricing InsightsNewsAug.06,2025

-

Advancing Container Manufacturing: The Role of the Modern Can Welding MachineNewsAug.06,2025

-

Understanding Automatic Seam Welding Machines: A Game Changer in Welding TechnologyNewsJul.18,2025

related products

-

Pneumatic Handle Welding MachineSep . 13, 2024

Pneumatic Handle Welding MachineSep . 13, 2024 -

Fully Automatic Kaiping Production LineOct . 17, 2024

Fully Automatic Kaiping Production LineOct . 17, 2024 -

Fully Automatic Metal Bucket Lifting HeadphonesSep . 14, 2024

Fully Automatic Metal Bucket Lifting HeadphonesSep . 14, 2024