-

8613931787312

8613931787312 -

Botou Industrial Zone on the east side of National Highway 104, Botou City, Hebei Province

Botou Industrial Zone on the east side of National Highway 104, Botou City, Hebei Province

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- haitian_creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- scottish-gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

ינו . 14, 2025 10:01

Back to list

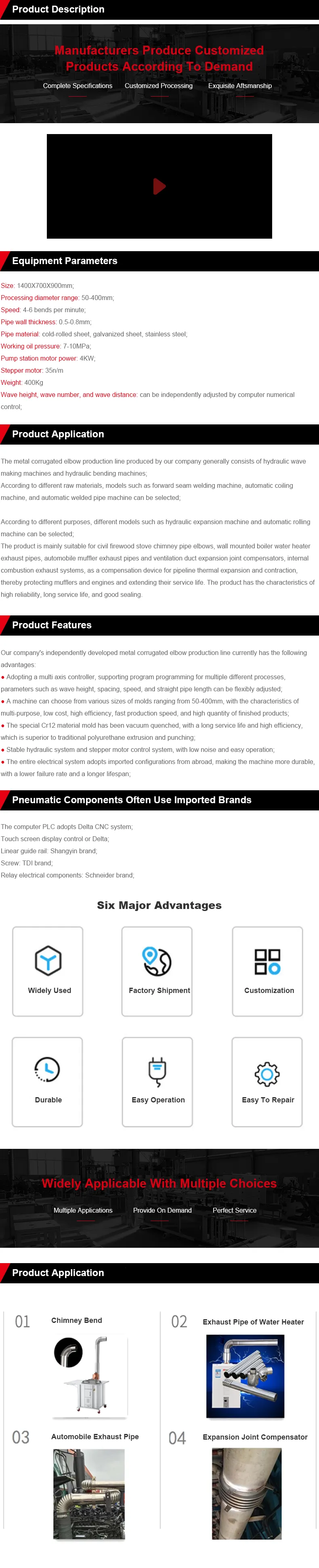

stainless steel tube bender

Investing in a stainless steel tube bender can significantly enhance the capability and efficiency of metalworking projects. With its ability to meticulously manipulate and shape stainless steel tubes, this tool is indispensable for various industries including automotive, construction, and even artistic endeavors. Here, we dive into real-world insights and expert knowledge to help you navigate the benefits and considerations when choosing the right stainless steel tube bender for your needs.

Authority in this domain comes from consistent application and the ability to adapt to technological advancements. Recent innovations include the integration of digital interfaces and software solutions which allow for precision engineering and minimized human error. Such technological enhancements not only improve operational productivity but also extend the lifespan of the machinery through optimized usage patterns. Trustworthiness in your selection process can be fortified by consulting reviews and testimonials from industry veterans who have extensively utilized these machines. Furthermore, opting for manufacturers with solid reputations and after-sales support can mitigate risks associated with potential malfunctions or technical difficulties. Maintenance of a stainless steel tube bender is another critical aspect that ensures long-term functionality and reliability. Regular inspections and adherence to the manufacturer's guidelines for lubrication and part replacements can prevent unplanned downtimes. Moreover, training operators to handle the machine correctly can avert common mishaps and prolong the equipment's operational life. In conclusion, a stainless steel tube bender is a powerful investment that can enhance productivity and quality in metalworking projects. By leveraging both expertise and technological advancements, businesses can achieve unparalleled precision in tube bending applications. Remember to assess your project's specific needs, keep abreast of the latest developments, and maintain the integrity of your equipment to make the most of your investment in a stainless steel tube bender.

Authority in this domain comes from consistent application and the ability to adapt to technological advancements. Recent innovations include the integration of digital interfaces and software solutions which allow for precision engineering and minimized human error. Such technological enhancements not only improve operational productivity but also extend the lifespan of the machinery through optimized usage patterns. Trustworthiness in your selection process can be fortified by consulting reviews and testimonials from industry veterans who have extensively utilized these machines. Furthermore, opting for manufacturers with solid reputations and after-sales support can mitigate risks associated with potential malfunctions or technical difficulties. Maintenance of a stainless steel tube bender is another critical aspect that ensures long-term functionality and reliability. Regular inspections and adherence to the manufacturer's guidelines for lubrication and part replacements can prevent unplanned downtimes. Moreover, training operators to handle the machine correctly can avert common mishaps and prolong the equipment's operational life. In conclusion, a stainless steel tube bender is a powerful investment that can enhance productivity and quality in metalworking projects. By leveraging both expertise and technological advancements, businesses can achieve unparalleled precision in tube bending applications. Remember to assess your project's specific needs, keep abreast of the latest developments, and maintain the integrity of your equipment to make the most of your investment in a stainless steel tube bender.

Prev:

Next:

Latest News

-

The Rise of Laser Welding: Precision Meets Power in Modern MetalworkNewsAug.06,2025

-

Streamlining Industrial Packaging: The Power of Barrel Production LinesNewsAug.06,2025

-

Revolutionizing Metal Joining: The Power of Automatic Seam Welding MachinesNewsAug.06,2025

-

Powering Industrial Innovation: The Role of Pipe and Tube Machinery in Modern ManufacturingNewsAug.06,2025

-

Exploring the World of Resistance Welding: Equipment, Manufacturers, and Pricing InsightsNewsAug.06,2025

-

Advancing Container Manufacturing: The Role of the Modern Can Welding MachineNewsAug.06,2025

-

Understanding Automatic Seam Welding Machines: A Game Changer in Welding TechnologyNewsJul.18,2025

related products

-

Pneumatic Handle Welding MachineSep . 13, 2024

Pneumatic Handle Welding MachineSep . 13, 2024 -

Fully Automatic Kaiping Production LineOct . 17, 2024

Fully Automatic Kaiping Production LineOct . 17, 2024 -

Fully Automatic Metal Bucket Lifting HeadphonesSep . 14, 2024

Fully Automatic Metal Bucket Lifting HeadphonesSep . 14, 2024