-

8613931787312

8613931787312 -

Botou Industrial Zone on the east side of National Highway 104, Botou City, Hebei Province

Botou Industrial Zone on the east side of National Highway 104, Botou City, Hebei Province

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- haitian_creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- scottish-gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

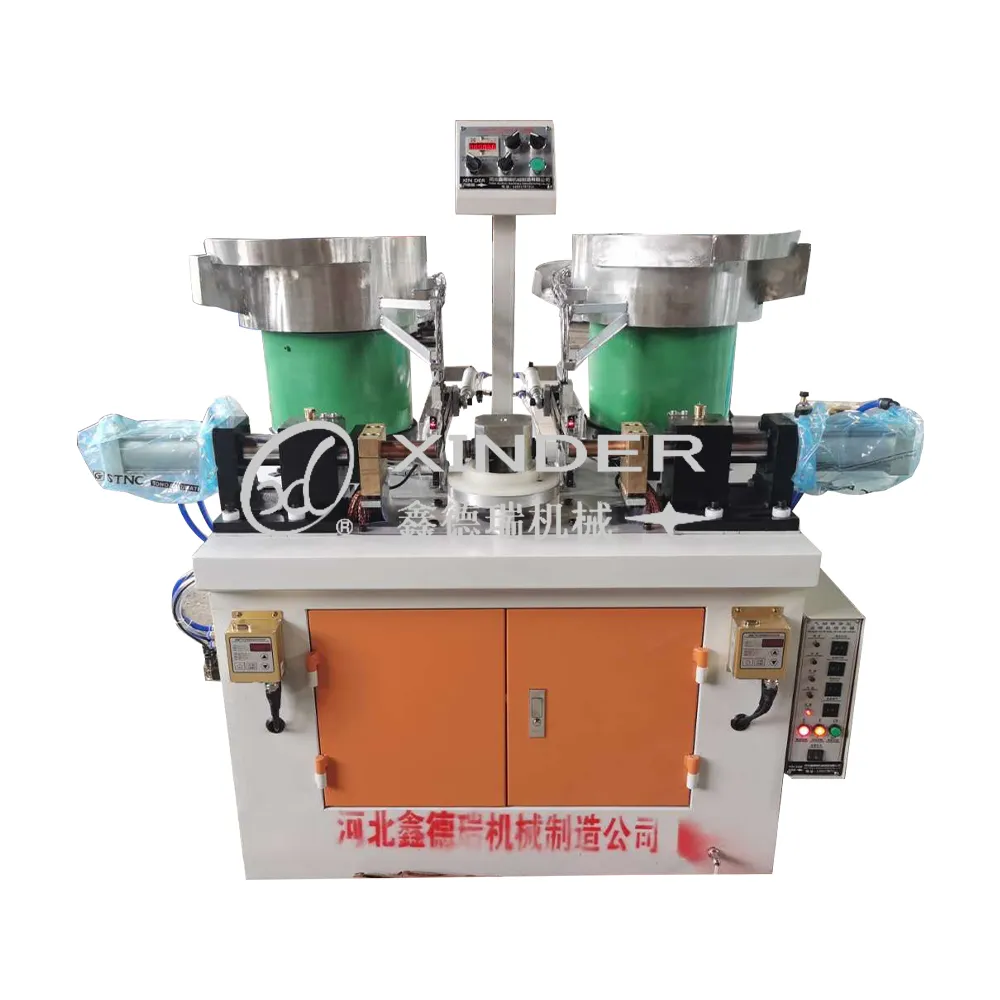

Pneumatic Spot Welder: Auto Welding Machine for Precision

The Evolution of Precision: Understanding Modern Resistance Welding

In the dynamic landscape of industrial manufacturing, the quest for efficiency, precision, and durability drives continuous innovation. Resistance welding, particularly the application of advanced pneumatic spot welder technology, stands at the forefront of this evolution. These machines are pivotal in industries demanding robust and consistent metal joining, from automotive and aerospace to electronics and appliance manufacturing. The shift towards automated and highly controllable welding solutions, such as the Fully automatic pneumatic double ear spot welding machine, reflects a broader industry trend focusing on enhancing productivity, reducing labor costs, and ensuring superior weld quality. Our discussion will delve into the intricate aspects of this technology, exploring its operational mechanics, diverse applications, and the inherent advantages it brings to complex production lines. We aim to provide a comprehensive understanding for B2B decision-makers and technical professionals seeking to optimize their welding processes.

The market for resistance welding equipment is experiencing steady growth, fueled by increasing automation in manufacturing and the rising demand for lightweight yet strong materials. Industry reports indicate a significant compound annual growth rate (CAGR) for spot welding equipment, driven by sectors like electric vehicle production and consumer electronics, which require highly reliable and precise joining techniques. The integration of advanced control systems, such as Programmable Logic Controllers (PLCs) and Human-Machine Interfaces (HMIs), into modern pneumatic spot welder units allows for unprecedented levels of precision, repeatability, and data logging, crucial for quality assurance and compliance with stringent industry standards. This technological sophistication enables manufacturers to achieve consistent weld nuggets with optimal mechanical properties, minimizing rework and material waste.

Manufacturing Excellence: The Anatomy of a High-Performance Pneumatic Spot Welder

The production of a high-quality pneumatic spot welder involves a meticulous multi-stage manufacturing process, ensuring robust performance and an extended operational lifespan. It commences with the selection of premium-grade materials, often including high-strength copper alloys for electrodes due to their superior electrical conductivity and heat resistance, and aerospace-grade steel for structural components to guarantee mechanical integrity. Key manufacturing processes include precision CNC machining for critical components like electrode holders and cylinder assemblies, ensuring exact tolerances and optimal alignment. For robust frame structures, techniques like high-pressure die casting or precision forging are employed, followed by heat treatment to enhance material strength and fatigue resistance. These foundational steps ensure the structural integrity and long-term reliability of the welding machine, laying the groundwork for its high-performance capabilities in demanding industrial environments.

Quality control is integrated at every stage, from raw material inspection to final assembly and testing. Components undergo rigorous non-destructive testing, such as ultrasonic inspection and eddy current testing, to detect any internal flaws. Critical dimensions are verified using CMM (Coordinate Measuring Machine) systems to ensure adherence to tight engineering specifications. Final product assembly is followed by comprehensive performance testing, including durability cycles, weld consistency tests, and electrical safety checks, all performed in accordance with international standards like ISO 9001 for quality management and ANSI/AWS (American National Standards Institute/American Welding Society) for welding equipment performance. This stringent quality assurance ensures that each pneumatic spot welder delivers consistent, high-quality welds and boasts an impressive service life, typically exceeding 10-15 years with proper maintenance, significantly reducing total cost of ownership for industrial clients.

Technical Specifications: Unpacking the Power of the Pneumatic Spot Welder

Understanding the core technical parameters of a pneumatic spot welder is crucial for selecting the right equipment for specific industrial applications. These specifications dictate the machine's capacity, precision, and operational efficiency. Below is a detailed table outlining typical parameters found in advanced pneumatic spot welding machines, including the specific capabilities of our Fully automatic pneumatic double ear spot welding machine, designed for high-volume, precision tasks. These figures represent the robust engineering and advanced control systems that ensure optimal weld quality across various materials and thicknesses, making it an ideal choice for diverse manufacturing needs, from thin sheet metal to complex assemblies.

| Parameter | Typical Range for Pneumatic Spot Welders | Fully Automatic Double Ear Spot Welding Machine |

|---|---|---|

| Input Power | 380V/50Hz (3-Phase) - 480V/60Hz (3-Phase) | 380V/50Hz (3-Phase) |

| Rated Power Capacity | 50 kVA - 200 kVA | 75 kVA |

| Welding Current Range | 5,000 A - 30,000 A | Up to 20,000 A (Adjustable) |

| Electrode Force (Pneumatic) | 2 kN - 10 kN (450 lbf - 2250 lbf) | 5 kN (Adjustable) |

| Welding Speed (Spots/Min) | 30 - 150 | Up to 120 (Dual Head Operation) |

| Cooling System | Water Cooling (Closed Loop) | Integrated Water Cooling |

| Applicable Material Thickness | 0.3 mm - 8.0 mm (Steel, Stainless, Galvanized) | 0.5 mm - 4.0 mm (Double Layer) |

| Control System | Microprocessor / PLC with HMI | Advanced PLC with Touch Screen HMI |

The adjustable parameters like welding current and electrode force are critical for achieving optimal "nugget" formation – the fused area at the spot weld. Too little current or force can result in weak welds, while too much can lead to excessive indentation or expulsion of molten metal. The sophisticated control systems, often utilizing real-time feedback loops, ensure precise control over these variables, leading to consistent weld integrity and minimal material deformation. This meticulous control is particularly beneficial in applications where aesthetic finish and structural strength are equally important, setting advanced auto spot welding machine apart from conventional methods.

Versatile Applications and Unmatched Advantages

Pneumatic spot welder systems are indispensable across a broad spectrum of industries, owing to their ability to produce strong, clean, and reliable joints on various metal types. In the petrochemical industry, they are used for fabricating intricate pipe supports, pressure vessel components, and structural elements that require high resistance to corrosion and extreme temperatures. For metallurgy, these welders are essential in the creation of components for furnaces, smelting equipment, and material handling systems, where material integrity under stress is paramount. In water supply and drainage systems, they ensure the leak-proof assembly of pipes, tanks, and valves, contributing to system longevity and preventing costly failures due to corrosion. The precision of these machines ensures that welds meet strict industry standards, preventing material degradation and ensuring operational safety.

The advantages of utilizing an advanced auto spot welding machine are manifold. Firstly, their precision significantly enhances energy efficiency by concentrating heat precisely at the weld area, minimizing heat-affected zones (HAZ) and reducing overall power consumption compared to traditional welding methods. Secondly, the robust and uniform welds produced offer superior corrosion resistance, particularly when working with coated or stainless steel, as the rapid heating and cooling cycle reduces material sensitization. This is crucial for applications exposed to harsh environmental conditions. Furthermore, the automation capabilities inherent in a Fully automatic pneumatic double ear spot welding machine lead to substantial labor savings, increased throughput, and exceptional repeatability, ensuring every weld meets the highest quality specifications without manual intervention. This combination of efficiency, durability, and automation provides a compelling return on investment for industrial clients.

Choosing Your Partner: Vendor Comparison and Custom Solutions

When investing in a pneumatic spot welder, discerning manufacturers consider several critical factors beyond initial cost. Key differentiators among vendors include: the breadth of their product portfolio, indicating their expertise in various welding applications; the quality of after-sales support and technical assistance; the availability of spare parts; and the vendor's reputation for reliability and innovation. Evaluating a vendor's commitment to R&D and their capacity for providing cutting-edge solutions, such as integrated robotic welding cells or vision systems for quality inspection, is also crucial. A thorough due diligence process ensures that the chosen partner can provide not just a machine, but a complete, sustainable welding solution tailored to evolving production demands.

Recognizing that off-the-shelf solutions may not always suffice, leading manufacturers offer highly customized welding solutions. This includes designing auto spot welding machine units with specific throat depths, electrode configurations, or multi-head setups to accommodate unique part geometries or production volumes. For instance, our Fully automatic pneumatic double ear spot welding machine can be adapted with specialized tooling for diverse component sizes or integrated into existing assembly lines with bespoke automation features. This collaborative approach allows clients to achieve optimal manufacturing workflows, addressing specific bottlenecks and maximizing efficiency. Our engineers work closely with clients to develop solutions that align precisely with their operational requirements, ensuring seamless integration and optimized performance.

Real-World Impact: Application Case Study

A prominent automotive component manufacturer faced challenges in maintaining consistent weld quality and increasing throughput for their exhaust system assembly. Traditional manual spot welding methods were prone to human error and limited by speed. Implementing our Fully automatic pneumatic double ear spot welding machine, customized with robotic part loading and unloading, transformed their production line. The machine's precise control over welding parameters and its dual-head operation significantly increased welding speed by 40% while simultaneously reducing weld defects by 25%. This led to a substantial improvement in overall product quality and a notable reduction in material waste and rework.

Furthermore, the integrated real-time monitoring system provided comprehensive data on each weld, enabling proactive maintenance and continuous process optimization. This successful deployment of an advanced auto spot welding machine not only improved operational metrics but also bolstered the manufacturer's reputation for producing high-quality, durable automotive parts. The client reported a significant return on investment within 18 months, primarily due to increased production efficiency and reduced quality control costs. This case exemplifies how precision engineering and automation in a pneumatic spot welder can drive tangible business advantages.

Ensuring Trust: Our Commitment to Quality and Support

Frequently Asked Questions (FAQ)

-

Q: What is the typical lead time for a custom pneumatic spot welder?

A: Standard models typically have a lead time of 4-6 weeks. For highly customized solutions, lead times can range from 8-12 weeks, depending on complexity and specific component sourcing. We provide a detailed project timeline upon order confirmation.

-

Q: What kind of maintenance does a pneumatic spot welder require?

A: Regular maintenance includes checking electrode tips for wear, ensuring proper water cooling flow, inspecting air pressure and lines, and periodic calibration of welding parameters. A detailed maintenance schedule is provided with each machine, typically requiring daily checks and monthly/quarterly deeper inspections.

-

Q: Are training and installation services provided?

A: Yes, we offer comprehensive installation services and on-site training for your operators and maintenance personnel. Our engineers ensure seamless integration into your production line and empower your team with the knowledge to operate and maintain the auto spot welding machine effectively.

Delivery Cycle & Warranty

Our streamlined production and logistics ensure efficient delivery. Typical delivery for standard pneumatic spot welder units is 4-6 weeks from order confirmation. For custom configurations, this may extend to 8-12 weeks. All our products, including the Fully automatic pneumatic double ear spot welding machine, come with a comprehensive 2-year warranty covering parts and labor, reflecting our confidence in their superior build quality and reliability. Extended warranty options are also available to provide long-term peace of mind.

Dedicated Customer Support

We are committed to providing unparalleled post-sales support. Our dedicated technical support team is available for remote assistance, troubleshooting, and guidance. For complex issues, on-site service by certified technicians can be arranged promptly. We also maintain a comprehensive inventory of genuine spare parts to minimize downtime and ensure your auto spot welding machine operates at peak performance throughout its lifespan. Our long-standing commitment to customer satisfaction ensures that you receive the support needed to maximize your investment.

Further Reading and Academic References

- Davies, M. A. (2018). Advances in Resistance Welding Technologies for Lightweight Materials. Journal of Manufacturing Science and Engineering, 140(5), 051010.

- Zhang, Y., & Li, C. (2020). Numerical Simulation of Heat Transfer and Nugget Formation in Pneumatic Spot Welding. Welding in the World, 64(2), 291-300.

- American Welding Society. (2017). AWS C1.1M/C1.1:2017 - Recommended Practices for Resistance Welding.

- Kim, J. S., & Lee, S. J. (2019). Optimizing Electrode Force and Current Profiles for Enhanced Spot Weld Quality in High-Strength Steels. International Journal of Advanced Manufacturing Technology, 105(3), 1163-1175.

-

The Rise of Laser Welding: Precision Meets Power in Modern MetalworkNewsAug.06,2025

-

Streamlining Industrial Packaging: The Power of Barrel Production LinesNewsAug.06,2025

-

Revolutionizing Metal Joining: The Power of Automatic Seam Welding MachinesNewsAug.06,2025

-

Powering Industrial Innovation: The Role of Pipe and Tube Machinery in Modern ManufacturingNewsAug.06,2025

-

Exploring the World of Resistance Welding: Equipment, Manufacturers, and Pricing InsightsNewsAug.06,2025

-

Advancing Container Manufacturing: The Role of the Modern Can Welding MachineNewsAug.06,2025

-

Understanding Automatic Seam Welding Machines: A Game Changer in Welding TechnologyNewsJul.18,2025

-

Pneumatic Handle Welding MachineSep . 13, 2024

Pneumatic Handle Welding MachineSep . 13, 2024 -

Fully Automatic Kaiping Production LineOct . 17, 2024

Fully Automatic Kaiping Production LineOct . 17, 2024 -

Fully Automatic Metal Bucket Lifting HeadphonesSep . 14, 2024

Fully Automatic Metal Bucket Lifting HeadphonesSep . 14, 2024