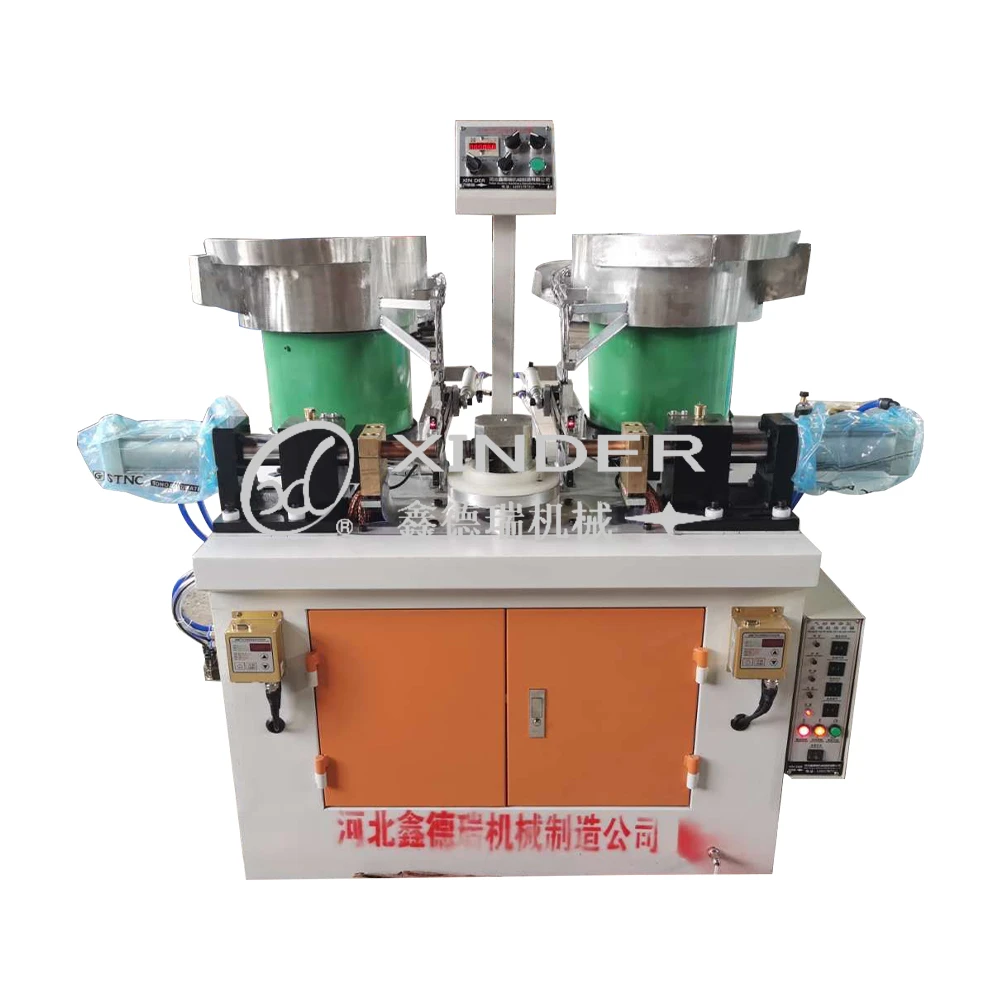

The Pneumatic Double Ear Spot Welding Machine is a high-efficiency, precision welding solution designed specifically for the production of metal parts requiring dual-point spot welding, such as double-ear components. This machine integrates pneumatic control with advanced welding technology, ensuring consistent weld quality, minimal deformation, and high repeatability.

Equipped with a robust pneumatic system, the machine offers stable pressure output and adjustable welding force, which allows for precise control of welding parameters based on material thickness and type. Its dual electrode setup enables simultaneous welding of both ears, significantly improving productivity and alignment accuracy compared to single-point machines. The high-performance copper alloy electrodes ensure excellent conductivity and long service life.

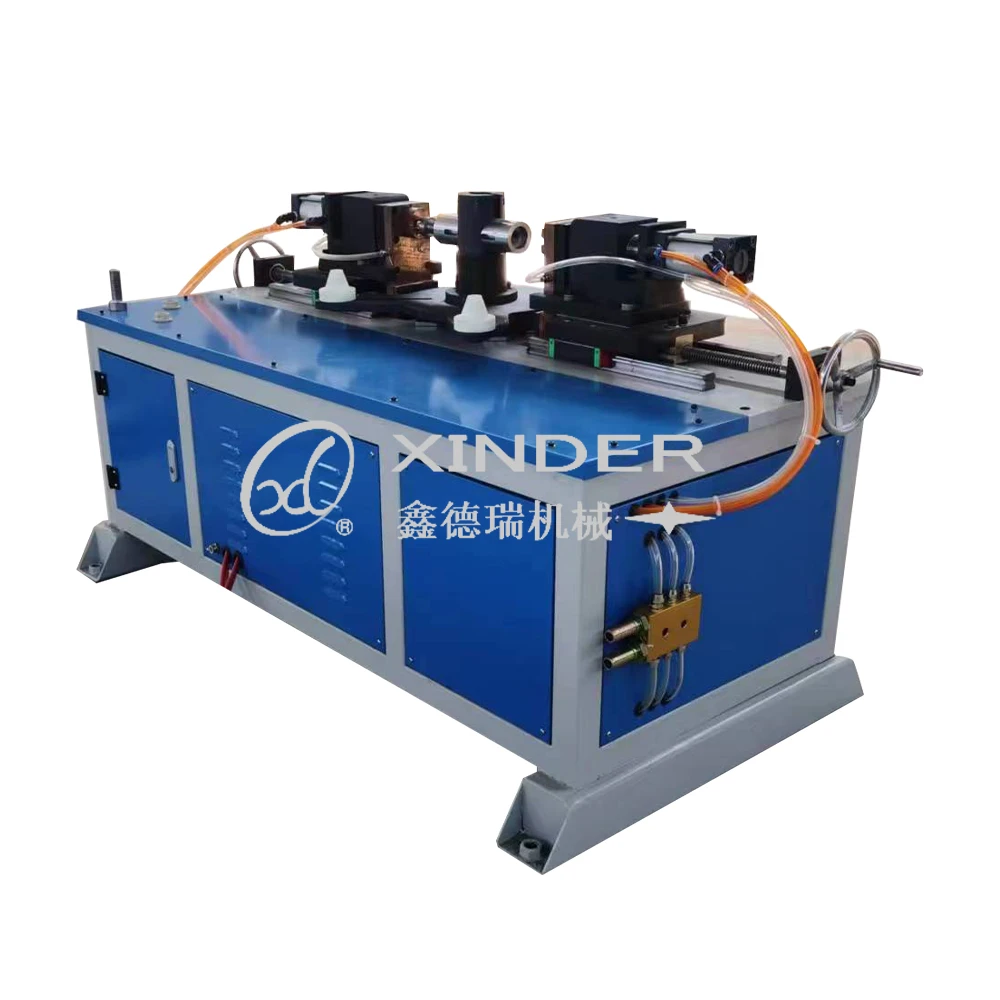

The machine frame is constructed from heavy-duty steel, providing vibration-free operation and superior structural rigidity. A user-friendly control panel allows easy parameter settings and monitoring, while safety features such as emergency stop buttons and thermal overload protection enhance operator security.

Designed for ease of maintenance, the welding heads are easily replaceable, and key components are accessible for quick servicing. Its compact footprint makes it ideal for integration into automated production lines or standalone use in workshop environments.

This spot welding machine is widely used in the manufacture of metal fittings, automotive components, and electrical accessories, where consistent and strong welds are critical. With its combination of precision, reliability, and efficiency, the Pneumatic Double Ear Spot Welding Machine is an essential tool for modern metalworking operations.

8613931787312

8613931787312  Botou Industrial Zone on the east side of National Highway 104, Botou City, Hebei Province

Botou Industrial Zone on the east side of National Highway 104, Botou City, Hebei Province