-

8613931787312

8613931787312 -

Botou Industrial Zone on the east side of National Highway 104, Botou City, Hebei Province

Botou Industrial Zone on the east side of National Highway 104, Botou City, Hebei Province

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- haitian_creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- scottish-gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Th2 . 18, 2025 05:07

Back to list

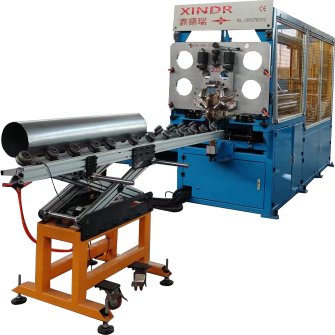

bucket and can making equipment assembly line

Crafting an efficient and reliable assembly line for bucket and can making equipment demands a blend of technical prowess and operational insight. Industry leaders in crafting such lines have discovered the key to success lies in a harmonious blend of technology, precision engineering, and meticulous quality control.

Another critical component is the human factor. While automation has revolutionized manufacturing, the expertise and experience of skilled engineers and technicians remain invaluable. Their deep understanding of the machinery and production processes enables them to manage, troubleshoot, and innovate, thus continuously enhancing the assembly line’s performance. Training programs and knowledge-sharing initiatives ensure that the workforce is always equipped with the latest skills and insights. Sustainability is increasingly a focal point for top-tier assembly lines. Companies are investing in eco-friendly technologies and processes, recognizing their responsibility towards environmental conservation. Energy-efficient machinery, waste reduction protocols, and recycling initiatives play pivotal roles in creating an assembly line that not only produces exceptional products but also prides itself on a commitment to sustainable practices. Building trust with clients and stakeholders is a cornerstone in the bucket and can manufacturing industry. Transparency in production processes, adherence to international quality and safety standards, and a robust after-sales support system are vital. Companies that excel in these areas earn reputations as industry authorities, fostering strong relationships with consumers and partners alike. In conclusion, excellence in bucket and can making equipment assembly lines is achieved through a strategic combination of cutting-edge technology, skilled human resources, rigorous quality checks, and a genuine commitment to sustainability and transparency. Companies that master these elements can produce superior products, maintain a competitive edge, and earn trust and respect in the global marketplace.

Another critical component is the human factor. While automation has revolutionized manufacturing, the expertise and experience of skilled engineers and technicians remain invaluable. Their deep understanding of the machinery and production processes enables them to manage, troubleshoot, and innovate, thus continuously enhancing the assembly line’s performance. Training programs and knowledge-sharing initiatives ensure that the workforce is always equipped with the latest skills and insights. Sustainability is increasingly a focal point for top-tier assembly lines. Companies are investing in eco-friendly technologies and processes, recognizing their responsibility towards environmental conservation. Energy-efficient machinery, waste reduction protocols, and recycling initiatives play pivotal roles in creating an assembly line that not only produces exceptional products but also prides itself on a commitment to sustainable practices. Building trust with clients and stakeholders is a cornerstone in the bucket and can manufacturing industry. Transparency in production processes, adherence to international quality and safety standards, and a robust after-sales support system are vital. Companies that excel in these areas earn reputations as industry authorities, fostering strong relationships with consumers and partners alike. In conclusion, excellence in bucket and can making equipment assembly lines is achieved through a strategic combination of cutting-edge technology, skilled human resources, rigorous quality checks, and a genuine commitment to sustainability and transparency. Companies that master these elements can produce superior products, maintain a competitive edge, and earn trust and respect in the global marketplace.

Prev:

Latest News

-

The Rise of Laser Welding: Precision Meets Power in Modern MetalworkNewsAug.06,2025

-

Streamlining Industrial Packaging: The Power of Barrel Production LinesNewsAug.06,2025

-

Revolutionizing Metal Joining: The Power of Automatic Seam Welding MachinesNewsAug.06,2025

-

Powering Industrial Innovation: The Role of Pipe and Tube Machinery in Modern ManufacturingNewsAug.06,2025

-

Exploring the World of Resistance Welding: Equipment, Manufacturers, and Pricing InsightsNewsAug.06,2025

-

Advancing Container Manufacturing: The Role of the Modern Can Welding MachineNewsAug.06,2025

-

Understanding Automatic Seam Welding Machines: A Game Changer in Welding TechnologyNewsJul.18,2025

related products

-

Pneumatic Handle Welding MachineSep . 13, 2024

Pneumatic Handle Welding MachineSep . 13, 2024 -

Fully Automatic Kaiping Production LineOct . 17, 2024

Fully Automatic Kaiping Production LineOct . 17, 2024 -

Fully Automatic Metal Bucket Lifting HeadphonesSep . 14, 2024

Fully Automatic Metal Bucket Lifting HeadphonesSep . 14, 2024