-

8613931787312

8613931787312 -

Botou Industrial Zone on the east side of National Highway 104, Botou City, Hebei Province

Botou Industrial Zone on the east side of National Highway 104, Botou City, Hebei Province

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- haitian_creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- scottish-gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Th2 . 20, 2025 02:50

Back to list

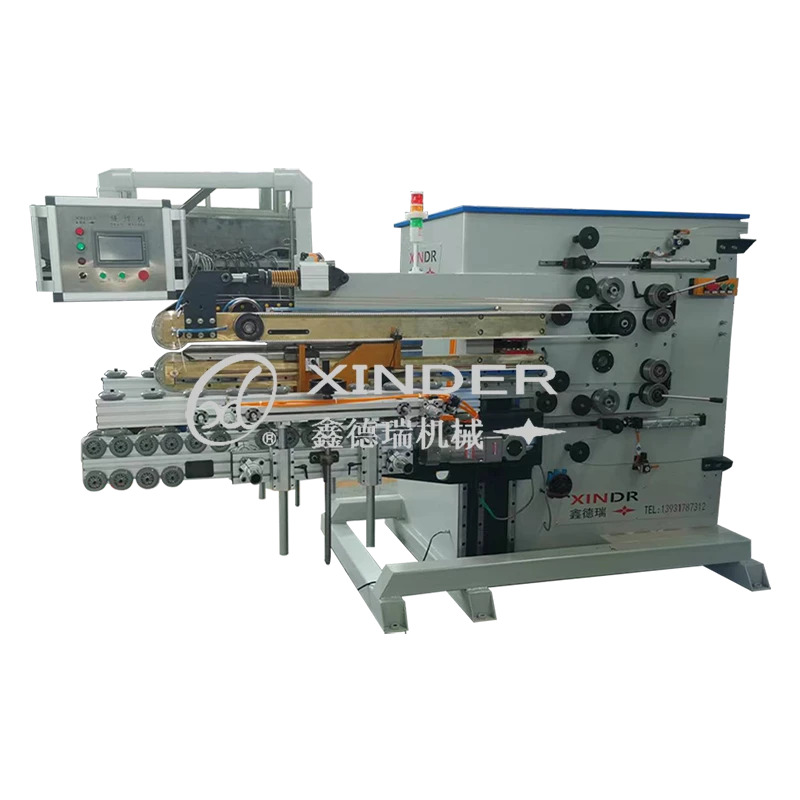

bottom sealing machine

Choosing a bottom sealing machine can significantly impact your production efficiency and product quality. These machines are pivotal in industries such as packaging, where durability and precision are non-negotiable. Drawing from years of expertise and in-field experience, this article highlights key aspects to consider in acquiring and operating a bottom sealing machine that meets industry standards and optimizes performance.

In addition to the machinery itself, the expertise of the operators plays a critical role in ensuring optimal performance. Training and experience are non-negotiable. Personnel should be well-versed in the machine's operating procedures, safety protocols, and troubleshooting techniques. This minimizes downtime and maintains the integrity and reliability of the sealing process, contributing to sustained product quality and customer satisfaction. From a maintenance perspective, regular servicing is vital to keep the machine functioning at peak performance. Establishing a maintenance schedule helps in identifying wear and tear issues before they escalate into major operational hindrances. Partner with manufacturers or certified service providers who can deliver expert insights and service solutions. Their authoritative knowledge becomes indispensable when addressing complex mechanical challenges or software updates that ensure the continued relevance and efficiency of the machinery. Lastly, the investment in a bottom sealing machine should be scrutinized for its return on investment (ROI). Consider the machine's durability, warranty, and the manufacturer’s reputation. Renowned brands usually offer machines with proven longevity and robust customer support, enhancing your operation's trustworthiness by guaranteeing uninterrupted service. An authoritative vendor also provides consultation services, helping to match your specific needs with the ideal machine model. Navigating the selection and operations of a bottom sealing machine requires a blend of expertise, experience, authoritativeness, and trustworthiness. By focusing on these aspects, businesses can ensure their packaging solutions not only meet but exceed industry standards, ultimately contributing to their success in the competitive market landscape.

In addition to the machinery itself, the expertise of the operators plays a critical role in ensuring optimal performance. Training and experience are non-negotiable. Personnel should be well-versed in the machine's operating procedures, safety protocols, and troubleshooting techniques. This minimizes downtime and maintains the integrity and reliability of the sealing process, contributing to sustained product quality and customer satisfaction. From a maintenance perspective, regular servicing is vital to keep the machine functioning at peak performance. Establishing a maintenance schedule helps in identifying wear and tear issues before they escalate into major operational hindrances. Partner with manufacturers or certified service providers who can deliver expert insights and service solutions. Their authoritative knowledge becomes indispensable when addressing complex mechanical challenges or software updates that ensure the continued relevance and efficiency of the machinery. Lastly, the investment in a bottom sealing machine should be scrutinized for its return on investment (ROI). Consider the machine's durability, warranty, and the manufacturer’s reputation. Renowned brands usually offer machines with proven longevity and robust customer support, enhancing your operation's trustworthiness by guaranteeing uninterrupted service. An authoritative vendor also provides consultation services, helping to match your specific needs with the ideal machine model. Navigating the selection and operations of a bottom sealing machine requires a blend of expertise, experience, authoritativeness, and trustworthiness. By focusing on these aspects, businesses can ensure their packaging solutions not only meet but exceed industry standards, ultimately contributing to their success in the competitive market landscape.

Latest News

-

The Rise of Laser Welding: Precision Meets Power in Modern MetalworkNewsAug.06,2025

-

Streamlining Industrial Packaging: The Power of Barrel Production LinesNewsAug.06,2025

-

Revolutionizing Metal Joining: The Power of Automatic Seam Welding MachinesNewsAug.06,2025

-

Powering Industrial Innovation: The Role of Pipe and Tube Machinery in Modern ManufacturingNewsAug.06,2025

-

Exploring the World of Resistance Welding: Equipment, Manufacturers, and Pricing InsightsNewsAug.06,2025

-

Advancing Container Manufacturing: The Role of the Modern Can Welding MachineNewsAug.06,2025

-

Understanding Automatic Seam Welding Machines: A Game Changer in Welding TechnologyNewsJul.18,2025

related products

-

Pneumatic Handle Welding MachineSep . 13, 2024

Pneumatic Handle Welding MachineSep . 13, 2024 -

Fully Automatic Kaiping Production LineOct . 17, 2024

Fully Automatic Kaiping Production LineOct . 17, 2024 -

Fully Automatic Metal Bucket Lifting HeadphonesSep . 14, 2024

Fully Automatic Metal Bucket Lifting HeadphonesSep . 14, 2024