-

8613931787312

8613931787312 -

Botou Industrial Zone on the east side of National Highway 104, Botou City, Hebei Province

Botou Industrial Zone on the east side of National Highway 104, Botou City, Hebei Province

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- haitian_creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- scottish-gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

فروری . 14, 2025 12:15

Back to list

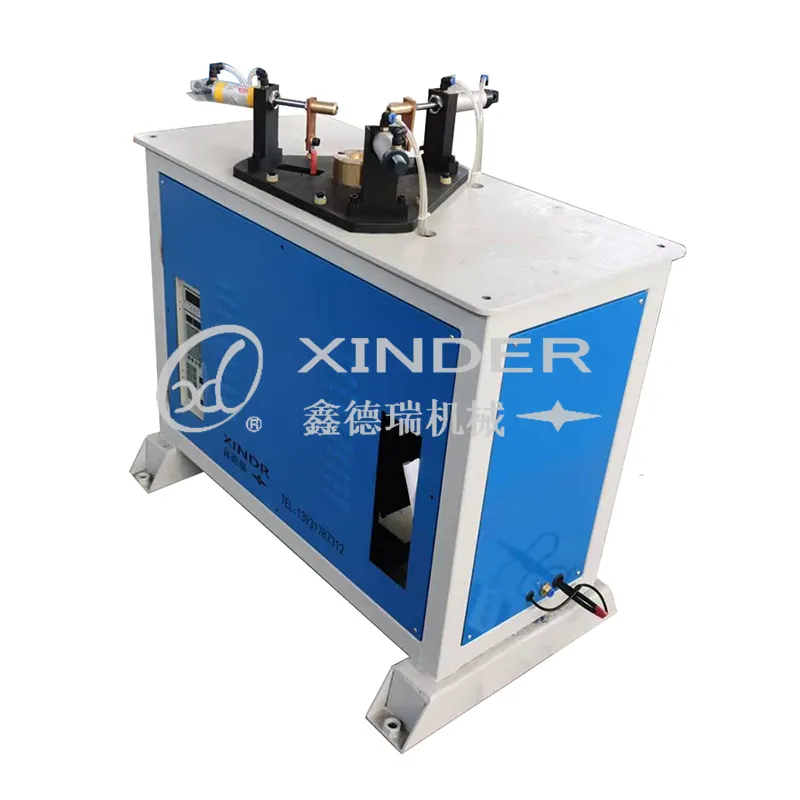

plain sheet bending machine

In the world of manufacturing and metalworking, the plain sheet bending machine stands as a pivotal instrument for fabricating precise metal components. With years of industry experience, I’ve seen firsthand how essential these machines are, transforming flat metal sheets into the complex shapes required by various industries. Whether it’s for automotive parts, construction materials, or aerospace applications, the expertise required to operate and maintain these machines directly correlates to the quality of the final products.

Moreover, the advent of CNC (Computer Numerical Control) technology has revolutionized sheet bending, ushering in an era where precision is married with speed. Expert operators embracing such technology are better equipped to handle intricate designs and large-scale production demands. CNC systems provide detailed feedback and data analysis, which are instrumental in refining bending processes and improving product accuracy. For industries demanding high standards of quality, the reliability of a plain sheet bending machine cannot be overstated. Partnering with reputable manufacturers ensures that the machines are built with durable materials and robust parts, guaranteeing longevity and optimal performance. Trusting in such authority also ensures that vital support and customer service are readily available, maintaining production efficiency and reducing downtime. Ensuring trustworthiness also extends to environmental considerations. Modern bending machines prioritize energy efficiency and sustainability. They are designed to minimize waste and conserve energy, reflecting a corporate responsibility towards greener manufacturing processes. Companies committed to reducing their carbon footprint find these machines align perfectly with sustainable business practices. In conclusion, the plain sheet bending machine is an intersection of technology, skill, and innovation. Its role in modern manufacturing is undeniable, offering unparalleled efficiency and accuracy. The equipment embodies a blend of traditional metalworking craftsmanship and futuristic technology, supporting an array of industries with high-quality, precisely-bent metal components. As technology evolves, so too will the capabilities of sheet bending machines, ensuring they remain central to the future of manufacturing processes. Investing in the right machine, and honing the right skills, will undoubtedly pave the way for continued growth and success in any metalworking field.

Moreover, the advent of CNC (Computer Numerical Control) technology has revolutionized sheet bending, ushering in an era where precision is married with speed. Expert operators embracing such technology are better equipped to handle intricate designs and large-scale production demands. CNC systems provide detailed feedback and data analysis, which are instrumental in refining bending processes and improving product accuracy. For industries demanding high standards of quality, the reliability of a plain sheet bending machine cannot be overstated. Partnering with reputable manufacturers ensures that the machines are built with durable materials and robust parts, guaranteeing longevity and optimal performance. Trusting in such authority also ensures that vital support and customer service are readily available, maintaining production efficiency and reducing downtime. Ensuring trustworthiness also extends to environmental considerations. Modern bending machines prioritize energy efficiency and sustainability. They are designed to minimize waste and conserve energy, reflecting a corporate responsibility towards greener manufacturing processes. Companies committed to reducing their carbon footprint find these machines align perfectly with sustainable business practices. In conclusion, the plain sheet bending machine is an intersection of technology, skill, and innovation. Its role in modern manufacturing is undeniable, offering unparalleled efficiency and accuracy. The equipment embodies a blend of traditional metalworking craftsmanship and futuristic technology, supporting an array of industries with high-quality, precisely-bent metal components. As technology evolves, so too will the capabilities of sheet bending machines, ensuring they remain central to the future of manufacturing processes. Investing in the right machine, and honing the right skills, will undoubtedly pave the way for continued growth and success in any metalworking field.

Latest News

-

The Rise of Laser Welding in Global Manufacturing: Spotlight on China’s Competitive EdgeNewsJun.05,2025

-

The Power of Precision: Exploring the Role of Automatic Seam Welding Machines in Modern ManufacturingNewsJun.05,2025

-

The Essential Guide to Can Welding Machines: Revolutionizing the Packaging IndustryNewsJun.05,2025

-

Resistance Welding Equipment: A Smart Investment for Industrial ManufacturingNewsJun.05,2025

-

Precision Welding for Modern Manufacturing: The Rise of Automatic Seam Welding MachinesNewsJun.05,2025

-

Laser Welding for Stainless Steel: The Precision Edge in Modern Metal FabricationNewsJun.05,2025

-

The Modern Evolution of Barrel Production: Technology, Machines, and Market PricingNewsMay.22,2025

related products

-

Pneumatic Handle Welding MachineSep . 13, 2024

Pneumatic Handle Welding MachineSep . 13, 2024 -

Fully Automatic Kaiping Production LineOct . 17, 2024

Fully Automatic Kaiping Production LineOct . 17, 2024 -

Fully Automatic Metal Bucket Lifting HeadphonesSep . 14, 2024

Fully Automatic Metal Bucket Lifting HeadphonesSep . 14, 2024