-

8613931787312

8613931787312 -

Botou Industrial Zone on the east side of National Highway 104, Botou City, Hebei Province

Botou Industrial Zone on the east side of National Highway 104, Botou City, Hebei Province

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- haitian_creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- scottish-gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

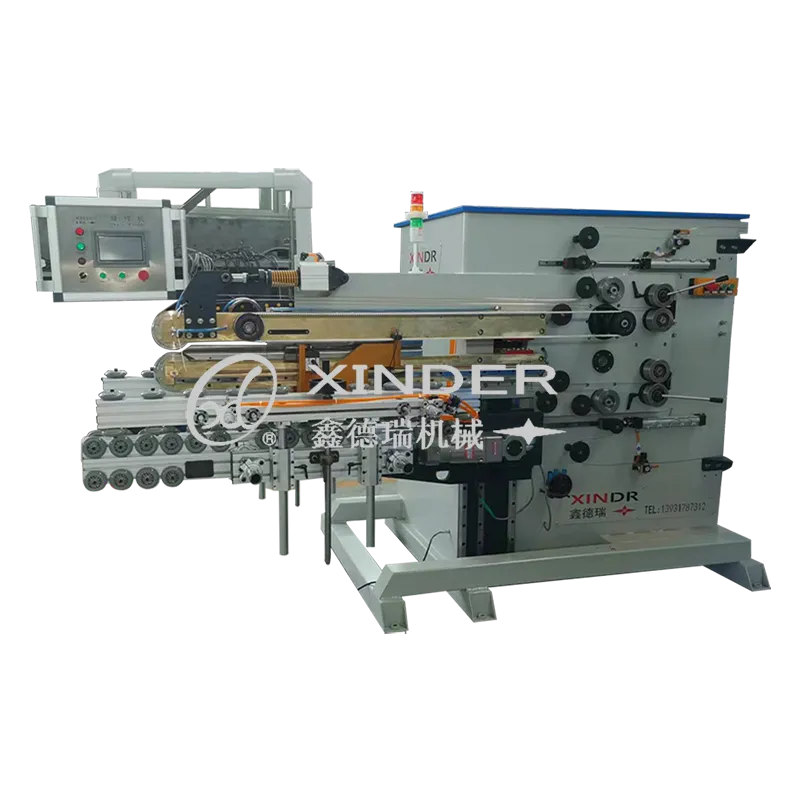

custom bending machine

The Versatility and Importance of Custom Bending Machines

In the world of manufacturing and metalworking, the demand for precision bending solutions has steadily increased. Custom bending machines have emerged as essential tools that cater to a broad spectrum of industries, including automotive, aerospace, construction, and metal fabrication. These machines are designed to meet the unique specifications of each project, providing flexibility and efficiency that standard equipment often cannot achieve.

Understanding Custom Bending Machines

Custom bending machines are specifically tailored to fit the unique needs of a manufacturer. While traditional bending machines provide general capabilities, customized machines incorporate specialized features that enhance performance and accuracy. These features may include adjustable bending angles, various tooling options, and compatibility with different materials. The ability to produce specific shapes and sizes ensures that manufacturers can meet their clients' unique requirements efficiently.

Key Benefits of Custom Bending Machines

1. Precision and Accuracy One of the primary advantages of custom bending machines is their ability to deliver precise bends that meet stringent tolerances. This level of accuracy is crucial in industries such as aerospace, where even slight deviations can result in catastrophic failures.

2. Increased Efficiency By tailoring machines to specific tasks, manufacturers can reduce setup time and optimize production processes. Custom machines can automate several bending processes, allowing for faster production times without compromising quality.

3. Versatility Custom bending machines can accommodate various materials, including stainless steel, aluminum, and other metals. This versatility enables manufacturers to diversify their product offerings and adapt to market demands quickly.

4. Reduced Waste With increased accuracy and efficiency comes reduced material wastage. Custom machines can create parts that fit together seamlessly, minimizing the need for additional machining or adjustments. This not only lowers costs but also promotes environmentally friendly manufacturing practices.

custom bending machine

Applications in Various Industries

The applications of custom bending machines are vast and varied

. In the automotive industry, for example, manufacturers use these machines to create complex components like exhaust systems, frames, and structural supports that require intricate bends and curves.In the aerospace sector, custom bending machines are employed to fabricate lightweight yet strong components essential for aircraft performance. Precision bending of materials like titanium and aluminum ensures that all parts fit together perfectly, which is critical for aircraft safety and efficiency.

The construction industry also benefits significantly from custom bending solutions. Curved steel beams, for instance, are often required in modern architectural designs. Custom bending machines provide the means to create these components accurately, enhancing the aesthetic appeal of buildings and structures.

Future Trends

As technology continues to advance, the future of custom bending machines looks promising. Incorporating features such as computer numerical control (CNC) technology allows for even greater precision and automation. This integration streamlines the manufacturing process and enables real-time adjustments based on design changes.

Additionally, the use of artificial intelligence (AI) in the programming of bending machines is also on the rise. AI can analyze previous bending patterns and make adjustments to optimize production further, predicting the best settings for achieving the desired results.

Conclusion

In conclusion, custom bending machines represent a critical component of modern manufacturing. Their ability to provide precision, efficiency, and versatility makes them invaluable in various sectors. As industries continue to evolve and demand greater customization, the importance of these machines will only increase. Manufacturers who invest in custom bending solutions position themselves for success in an ever-competitive market, meeting customer needs while enhancing productivity. As technology advances, we can expect even more innovative solutions that will redefine the capabilities of custom bending machines, solidifying their role as essential tools in the manufacturing landscape.

-

The Rise of Laser Welding: Precision Meets Power in Modern MetalworkNewsAug.06,2025

-

Streamlining Industrial Packaging: The Power of Barrel Production LinesNewsAug.06,2025

-

Revolutionizing Metal Joining: The Power of Automatic Seam Welding MachinesNewsAug.06,2025

-

Powering Industrial Innovation: The Role of Pipe and Tube Machinery in Modern ManufacturingNewsAug.06,2025

-

Exploring the World of Resistance Welding: Equipment, Manufacturers, and Pricing InsightsNewsAug.06,2025

-

Advancing Container Manufacturing: The Role of the Modern Can Welding MachineNewsAug.06,2025

-

Understanding Automatic Seam Welding Machines: A Game Changer in Welding TechnologyNewsJul.18,2025

-

Pneumatic Handle Welding MachineSep . 13, 2024

Pneumatic Handle Welding MachineSep . 13, 2024 -

Fully Automatic Kaiping Production LineOct . 17, 2024

Fully Automatic Kaiping Production LineOct . 17, 2024 -

Fully Automatic Metal Bucket Lifting HeadphonesSep . 14, 2024

Fully Automatic Metal Bucket Lifting HeadphonesSep . 14, 2024