-

8613931787312

8613931787312 -

Botou Industrial Zone on the east side of National Highway 104, Botou City, Hebei Province

Botou Industrial Zone on the east side of National Highway 104, Botou City, Hebei Province

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- haitian_creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- scottish-gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Січ . 17, 2025 03:32

Back to list

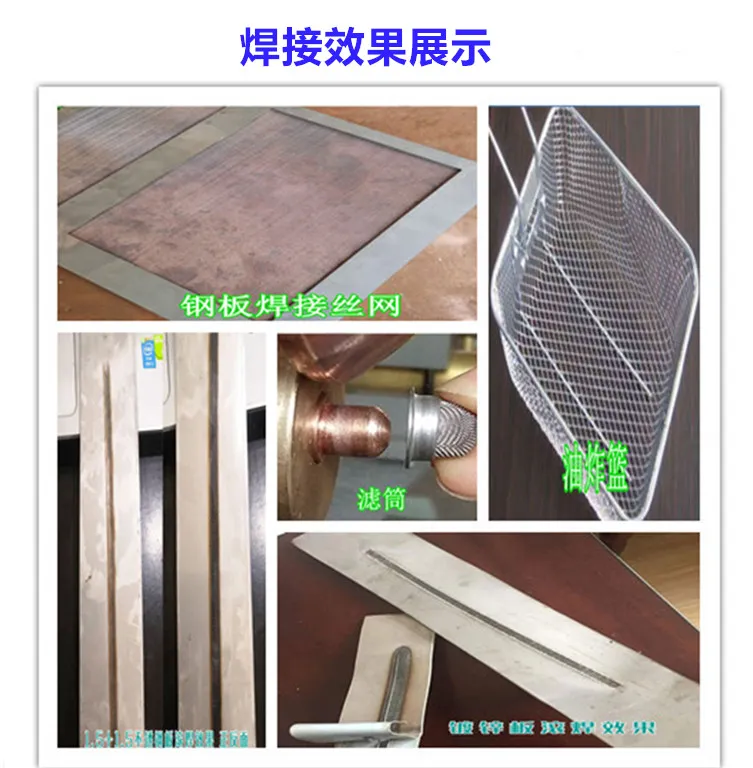

professional laser welding machine

Laser welding plants represent a pivotal advancement in manufacturing technologies, standing at the forefront of precision and efficiency. Emphasizing experience, expertise, authority, and trustworthiness, these plants serve as an epitome of modern engineering and industrial capabilities.

Trustworthiness is the ultimate hallmark of a reputable laser welding plant. Clients place immense trust in the plant’s ability to deliver defect-free, high-performance assemblies that meet stringent industrial standards. Building this trust involves detailed project planning, transparent communication, and adherence to industry regulations like ISO and ASTM. Forging a legacy of reliability, these plants often serve as cornerstones in critical industries such as aerospace, automotive, and medical devices, where the margin for error is virtually non-existent. A laser welding plant's commitment to sustainability is another testament to its responsible and forward-thinking ethos. By focusing on energy-efficient lasers and promoting zero-waste policies, these plants contribute to reducing the carbon footprint of manufacturing processes. This approach not only bolsters the environmental credentials of the industries they serve but also aligns with global sustainability targets. The incorporation of smart technologies and automation further enhances the operation of laser welding plants. Robotics and AI-driven analytics streamline the welding process, allowing for real-time monitoring and adjustments that optimize quality and throughput. This integration of cutting-edge technologies is reflective of the plant's unwavering dedication to excellence and innovation. In conclusion, a laser welding plant stands as a beacon of innovation, expertise, and trust in the manufacturing domain. These plants embody a sophisticated blend of experience and authority, driven by a commitment to deliver superior results while fostering trust and reliability among their clients. As they continue to evolve, laser welding plants are not merely keeping pace with technological advancements but are actively setting the stage for future innovations in manufacturing.

Trustworthiness is the ultimate hallmark of a reputable laser welding plant. Clients place immense trust in the plant’s ability to deliver defect-free, high-performance assemblies that meet stringent industrial standards. Building this trust involves detailed project planning, transparent communication, and adherence to industry regulations like ISO and ASTM. Forging a legacy of reliability, these plants often serve as cornerstones in critical industries such as aerospace, automotive, and medical devices, where the margin for error is virtually non-existent. A laser welding plant's commitment to sustainability is another testament to its responsible and forward-thinking ethos. By focusing on energy-efficient lasers and promoting zero-waste policies, these plants contribute to reducing the carbon footprint of manufacturing processes. This approach not only bolsters the environmental credentials of the industries they serve but also aligns with global sustainability targets. The incorporation of smart technologies and automation further enhances the operation of laser welding plants. Robotics and AI-driven analytics streamline the welding process, allowing for real-time monitoring and adjustments that optimize quality and throughput. This integration of cutting-edge technologies is reflective of the plant's unwavering dedication to excellence and innovation. In conclusion, a laser welding plant stands as a beacon of innovation, expertise, and trust in the manufacturing domain. These plants embody a sophisticated blend of experience and authority, driven by a commitment to deliver superior results while fostering trust and reliability among their clients. As they continue to evolve, laser welding plants are not merely keeping pace with technological advancements but are actively setting the stage for future innovations in manufacturing.

Latest News

-

The Rise of Laser Welding in Global Manufacturing: Spotlight on China’s Competitive EdgeNewsJun.05,2025

-

The Power of Precision: Exploring the Role of Automatic Seam Welding Machines in Modern ManufacturingNewsJun.05,2025

-

The Essential Guide to Can Welding Machines: Revolutionizing the Packaging IndustryNewsJun.05,2025

-

Resistance Welding Equipment: A Smart Investment for Industrial ManufacturingNewsJun.05,2025

-

Precision Welding for Modern Manufacturing: The Rise of Automatic Seam Welding MachinesNewsJun.05,2025

-

Laser Welding for Stainless Steel: The Precision Edge in Modern Metal FabricationNewsJun.05,2025

-

The Modern Evolution of Barrel Production: Technology, Machines, and Market PricingNewsMay.22,2025

related products

-

Pneumatic Handle Welding MachineSep . 13, 2024

Pneumatic Handle Welding MachineSep . 13, 2024 -

Fully Automatic Kaiping Production LineOct . 17, 2024

Fully Automatic Kaiping Production LineOct . 17, 2024 -

Fully Automatic Metal Bucket Lifting HeadphonesSep . 14, 2024

Fully Automatic Metal Bucket Lifting HeadphonesSep . 14, 2024