-

8613931787312

8613931787312 -

Botou Industrial Zone on the east side of National Highway 104, Botou City, Hebei Province

Botou Industrial Zone on the east side of National Highway 104, Botou City, Hebei Province

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- haitian_creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- scottish-gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Oca . 11, 2025 12:47

Back to list

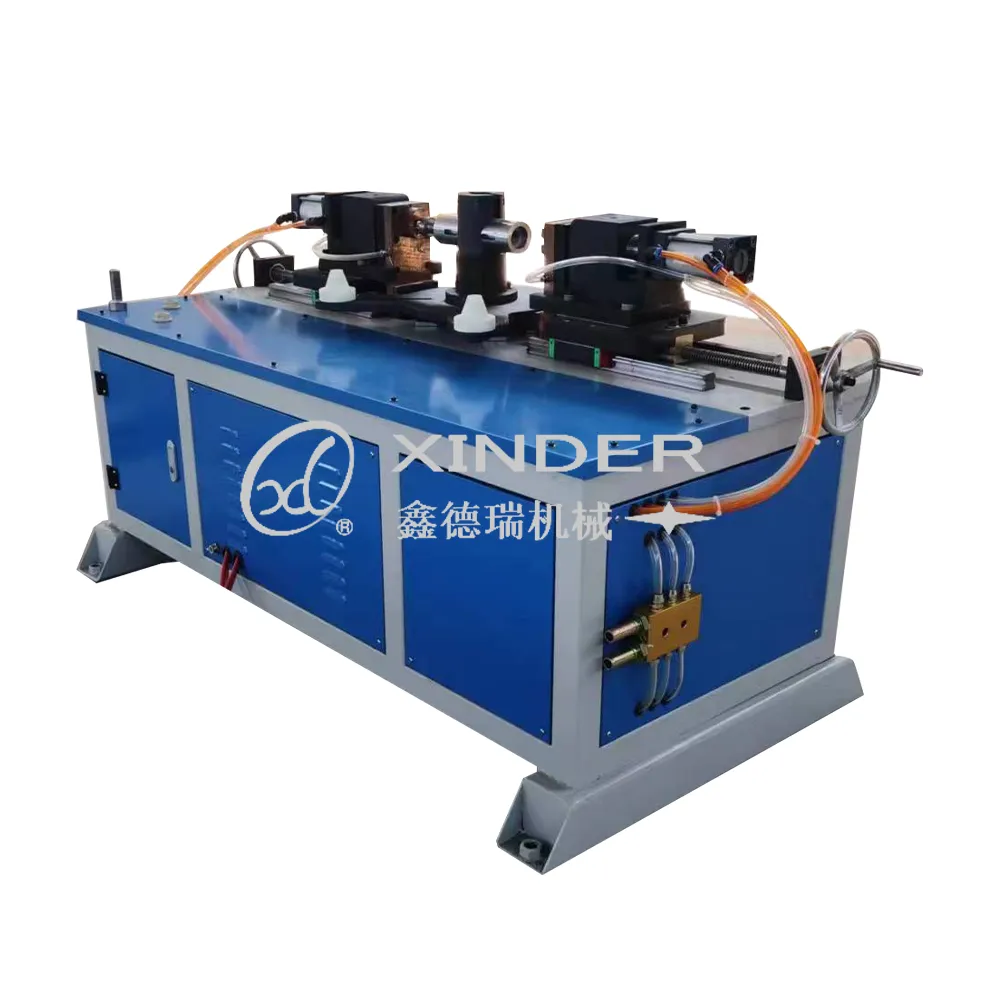

Fully Automatic Steel Barrel Straight Seam Laser Welding Machine

Laser welding automation has revolutionized the manufacturing landscape, offering unparalleled precision, efficiency, and flexibility. In an era where technological advancements dictate the market leaders, understanding the comprehensive benefits and applications of laser welding automation can serve as a critical differentiator for enterprises aiming for top-tier production capabilities.

Trustworthiness within this automation technology is further emphasized by its repeatability and consistency. Unlike manual welding, where the quality can vary significantly from one artisan to another, laser welding automation ensures uniformity across production batches. This consistency is a cornerstone of quality assurance, vital for sectors such as automotive and medical devices where safety and reliability cannot be compromised. Moreover, the laser welding process is clean and environmentally friendly, producing minimal greenhouse gases compared to traditional welding techniques. In an age where sustainable practices are not just preferable but essential, this aspect of laser welding amplifies its trustworthiness within eco-conscious industries. Enterprises investing in laser welding automation can expect a high return on investment, not only through cost savings but also by meeting product quality and sustainability demands that are increasingly important in today's markets. By aligning manufacturing capabilities with cutting-edge technology, businesses not only boost their production efficiency but also enhance their market reputation, paving the way for future growth and innovation. In conclusion, laser welding automation embodies the principles of Experience, Expertise, Authoritativeness, and Trustworthiness in the manufacturing domain. As an enabler of precision, efficiency, and sustainable production, it offers a compelling proposition for businesses seeking to innovate and excel in a competitive market. Embracing this technology is not just a step forward in manufacturing; it is a leap towards the future of industry standards.

Trustworthiness within this automation technology is further emphasized by its repeatability and consistency. Unlike manual welding, where the quality can vary significantly from one artisan to another, laser welding automation ensures uniformity across production batches. This consistency is a cornerstone of quality assurance, vital for sectors such as automotive and medical devices where safety and reliability cannot be compromised. Moreover, the laser welding process is clean and environmentally friendly, producing minimal greenhouse gases compared to traditional welding techniques. In an age where sustainable practices are not just preferable but essential, this aspect of laser welding amplifies its trustworthiness within eco-conscious industries. Enterprises investing in laser welding automation can expect a high return on investment, not only through cost savings but also by meeting product quality and sustainability demands that are increasingly important in today's markets. By aligning manufacturing capabilities with cutting-edge technology, businesses not only boost their production efficiency but also enhance their market reputation, paving the way for future growth and innovation. In conclusion, laser welding automation embodies the principles of Experience, Expertise, Authoritativeness, and Trustworthiness in the manufacturing domain. As an enabler of precision, efficiency, and sustainable production, it offers a compelling proposition for businesses seeking to innovate and excel in a competitive market. Embracing this technology is not just a step forward in manufacturing; it is a leap towards the future of industry standards.

Latest News

-

Understanding Resistance Welding: Equipment, Manufacturers, and PricingNewsMay.15,2025

-

Understanding Pneumatic Welding Machines: Types, Applications, and AdvantagesNewsMay.15,2025

-

Exploring Tube Benders: Types, Manufacturers, and ApplicationsNewsMay.15,2025

-

Exploring Metal Pipe Machines: Types, Functions, and ApplicationsNewsMay.15,2025

-

Exploring Laser Welding Machines: Key Manufacturers, Technology, and ApplicationsNewsMay.15,2025

-

Exploring Barrel Production Lines: Machines, Pricing, and Manufacturing ProcessNewsMay.15,2025

-

The Role of Steel Pipe Manufacturing Machines in Modern IndustriesNewsApr.18,2025

related products

-

Fully Automatic Kaiping Production LineOct . 17, 2024

Fully Automatic Kaiping Production LineOct . 17, 2024 -

Fully Automatic Metal Bucket Lifting HeadphonesSep . 14, 2024

Fully Automatic Metal Bucket Lifting HeadphonesSep . 14, 2024 -

Automatic Rolling MachineSep . 14, 2024

Automatic Rolling MachineSep . 14, 2024