-

8613931787312

8613931787312 -

Botou Industrial Zone on the east side of National Highway 104, Botou City, Hebei Province

Botou Industrial Zone on the east side of National Highway 104, Botou City, Hebei Province

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- haitian_creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- scottish-gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

ก.พ. . 20, 2025 05:00

Back to list

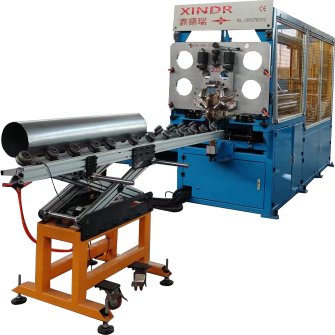

automatic seam welding machine

The circular pipe automatic welding machine has revolutionized the welding industry, enhancing efficiency and precision in projects that involve cylindrical structures. These machines serve a crucial role in various sectors, including construction, automotives, shipbuilding, and petrochemicals, where consistent and high-quality welds are non-negotiable. The technology promises not only accuracy but also sustainability in welding operations, meeting the rigorous standards required in modern industry.

From an expertise standpoint, manufacturers recommend a comprehensive approach to adopting these machines. Integrating them requires initial investments not only in equipment but also in upskilling existing personnel. Training programs are essential to ensure that operators can fully leverage the machine’s capabilities. A systematic training regimen, backed by technical documentation and support from manufacturers, plays a pivotal role in achieving the desired quality and productivity goals. Authority in automated welding technology stems from years of research and practical application. Leading companies in the industry have developed robust systems validated by certifications and industry standards. Their credibility is reinforced through collaborations with global institutions, focusing on continuous improvement and innovation in welding technologies. As a result, buyers and stakeholders exhibit high trust in these systems, acknowledging them as indispensable tools for competitive manufacturing. Trustworthiness is cemented by user testimonials and case studies that document transformative improvements in production lines. Clients report not only on the technical benefits but also on the operational safety and financial efficiencies gained through the deployment of these machines. Detailed feedback mechanisms contribute to ongoing enhancements, where manufacturers use real-world data to refine their systems and address user concerns promptly. In conclusion, the circular pipe automatic welding machine stands as a testament to the intersection of technology, expertise, and practicality. Its implementation across industries signifies a move towards more intelligent, sustainable, and safe manufacturing practices. As sectors continue to evolve and demand higher standards for weld quality and operational efficiency, these machines are poised to be at the forefront of innovation, achieving new benchmarks in industrial performance.

From an expertise standpoint, manufacturers recommend a comprehensive approach to adopting these machines. Integrating them requires initial investments not only in equipment but also in upskilling existing personnel. Training programs are essential to ensure that operators can fully leverage the machine’s capabilities. A systematic training regimen, backed by technical documentation and support from manufacturers, plays a pivotal role in achieving the desired quality and productivity goals. Authority in automated welding technology stems from years of research and practical application. Leading companies in the industry have developed robust systems validated by certifications and industry standards. Their credibility is reinforced through collaborations with global institutions, focusing on continuous improvement and innovation in welding technologies. As a result, buyers and stakeholders exhibit high trust in these systems, acknowledging them as indispensable tools for competitive manufacturing. Trustworthiness is cemented by user testimonials and case studies that document transformative improvements in production lines. Clients report not only on the technical benefits but also on the operational safety and financial efficiencies gained through the deployment of these machines. Detailed feedback mechanisms contribute to ongoing enhancements, where manufacturers use real-world data to refine their systems and address user concerns promptly. In conclusion, the circular pipe automatic welding machine stands as a testament to the intersection of technology, expertise, and practicality. Its implementation across industries signifies a move towards more intelligent, sustainable, and safe manufacturing practices. As sectors continue to evolve and demand higher standards for weld quality and operational efficiency, these machines are poised to be at the forefront of innovation, achieving new benchmarks in industrial performance.

Latest News

-

The Rise of Laser Welding: Precision Meets Power in Modern MetalworkNewsAug.06,2025

-

Streamlining Industrial Packaging: The Power of Barrel Production LinesNewsAug.06,2025

-

Revolutionizing Metal Joining: The Power of Automatic Seam Welding MachinesNewsAug.06,2025

-

Powering Industrial Innovation: The Role of Pipe and Tube Machinery in Modern ManufacturingNewsAug.06,2025

-

Exploring the World of Resistance Welding: Equipment, Manufacturers, and Pricing InsightsNewsAug.06,2025

-

Advancing Container Manufacturing: The Role of the Modern Can Welding MachineNewsAug.06,2025

-

Understanding Automatic Seam Welding Machines: A Game Changer in Welding TechnologyNewsJul.18,2025

related products

-

Pneumatic Handle Welding MachineSep . 13, 2024

Pneumatic Handle Welding MachineSep . 13, 2024 -

Fully Automatic Kaiping Production LineOct . 17, 2024

Fully Automatic Kaiping Production LineOct . 17, 2024 -

Fully Automatic Metal Bucket Lifting HeadphonesSep . 14, 2024

Fully Automatic Metal Bucket Lifting HeadphonesSep . 14, 2024