Characteristic

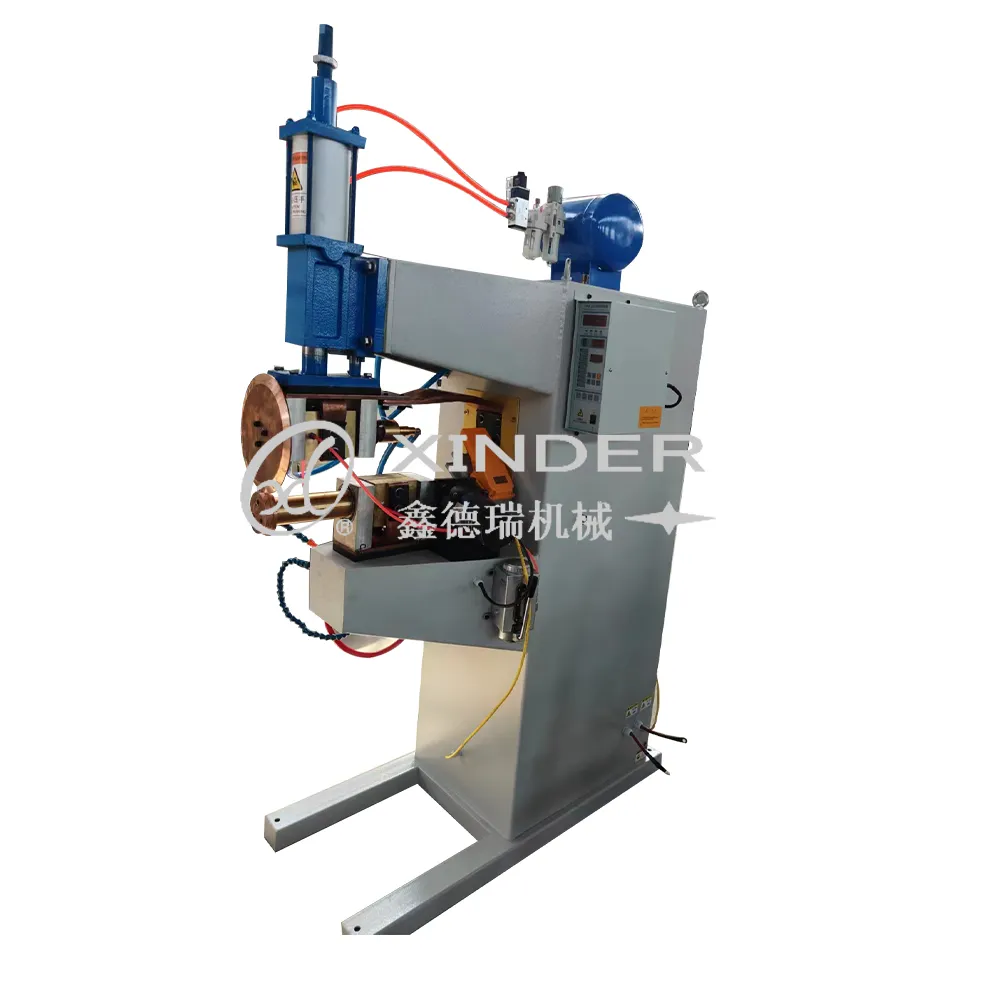

- Pressure mechanism: transmits pressure, evenly adjusts the pressure between the welding wheels, and can compensate for electrode wear;

- Welding wheel: using internal and external water cooling, the conductive block adopts a pure silver tile structure, with good conductivity and automatic compensation for silver tile wear function;

- Speed control transmission mechanism: adopts variable frequency speed control/gear reducer transmission;

- Seam welding machines come in two forms: vertical welding and horizontal welding, suitable for welding various workpieces. The transformer is made of all purple copper and conducts electricity with mercury.

Application Scope

Used for seam welding of enclosures such as car/motorcycle fuel tanks, barrels such as steel drums, and formed sheet metal workpieces such as wheels, sound-absorbing fins, radiators, etc. A seam welding machine usually consists of a frame, a pressure mechanism, a welding wheel (electrode), a welding power supply, a speed control transmission mechanism, and a controller.

Six Major Advantages

-

Widely Used

-

Widely Used

-

Widely Used

-

Widely Used

-

Widely Used

-

Widely Used

Write your message here and send it to us