-

8613931787312

8613931787312 -

Botou Industrial Zone on the east side of National Highway 104, Botou City, Hebei Province

Botou Industrial Zone on the east side of National Highway 104, Botou City, Hebei Province

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- haitian_creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- scottish-gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

జన . 20, 2025 10:08

Back to list

stainless steel drums for sale

Steel drums, known for their durability and versatility, play a crucial role across various industries. From storing hazardous chemicals in manufacturing plants to aging spirits in the beverage industry, these drums are indispensable. However, not all steel drums are created equal. Understanding the different types and their specifications is essential for leveraging their full potential while ensuring safety and cost-efficiency.

Another significant consideration is drum capacity. Steel drums generally come in 55-gallon sizes, but other variations can cater to specific needs. While larger drums are beneficial for bulk storage and transportation, smaller drums offer the flexibility needed in environments where space is a constraint or where precise amounts of materials are required. Regulatory compliance is another area where expertise is crucial. Steel drums used for transportation—especially of hazardous materials—must adhere to various national and international standards, such as the UN markings. Familiarity with these regulations ensures not only the legal compliance of operations but also the safety of handlers and integrity of the transported goods. The choice between reconditioned and new steel drums is also significant. Reconditioned drums offer a cost-effective solution, emphasizing sustainability through reuse. These drums undergo a rigorous cleaning and restoration process to meet safety and performance standards. However, for applications where material integrity cannot be compromised, new steel drums are preferred. They ensure compliance with the highest levels of quality and safety, minimizing risks associated with potential cross-contamination or structural wear. In conclusion, selecting the appropriate type of steel drum requires careful consideration of material compatibility, environmental conditions, regulatory requirements, and cost implications. Each type of steel drum brings unique strengths to the table, and understanding these nuances is key to optimizing their use. By embracing expert knowledge and adhering to regulatory standards, industries can ensure that they not only achieve operational efficiency but also maintain safety and sustainability in their processes.

Another significant consideration is drum capacity. Steel drums generally come in 55-gallon sizes, but other variations can cater to specific needs. While larger drums are beneficial for bulk storage and transportation, smaller drums offer the flexibility needed in environments where space is a constraint or where precise amounts of materials are required. Regulatory compliance is another area where expertise is crucial. Steel drums used for transportation—especially of hazardous materials—must adhere to various national and international standards, such as the UN markings. Familiarity with these regulations ensures not only the legal compliance of operations but also the safety of handlers and integrity of the transported goods. The choice between reconditioned and new steel drums is also significant. Reconditioned drums offer a cost-effective solution, emphasizing sustainability through reuse. These drums undergo a rigorous cleaning and restoration process to meet safety and performance standards. However, for applications where material integrity cannot be compromised, new steel drums are preferred. They ensure compliance with the highest levels of quality and safety, minimizing risks associated with potential cross-contamination or structural wear. In conclusion, selecting the appropriate type of steel drum requires careful consideration of material compatibility, environmental conditions, regulatory requirements, and cost implications. Each type of steel drum brings unique strengths to the table, and understanding these nuances is key to optimizing their use. By embracing expert knowledge and adhering to regulatory standards, industries can ensure that they not only achieve operational efficiency but also maintain safety and sustainability in their processes.

Latest News

-

The Rise of Laser Welding: Precision Meets Power in Modern MetalworkNewsAug.06,2025

-

Streamlining Industrial Packaging: The Power of Barrel Production LinesNewsAug.06,2025

-

Revolutionizing Metal Joining: The Power of Automatic Seam Welding MachinesNewsAug.06,2025

-

Powering Industrial Innovation: The Role of Pipe and Tube Machinery in Modern ManufacturingNewsAug.06,2025

-

Exploring the World of Resistance Welding: Equipment, Manufacturers, and Pricing InsightsNewsAug.06,2025

-

Advancing Container Manufacturing: The Role of the Modern Can Welding MachineNewsAug.06,2025

-

Understanding Automatic Seam Welding Machines: A Game Changer in Welding TechnologyNewsJul.18,2025

related products

-

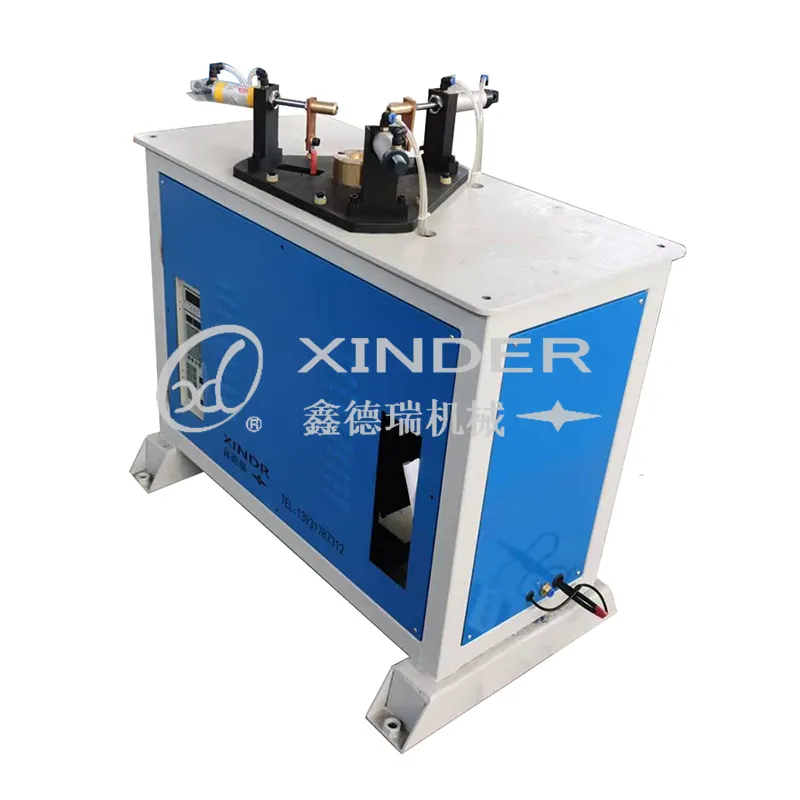

Pneumatic Handle Welding MachineSep . 13, 2024

Pneumatic Handle Welding MachineSep . 13, 2024 -

Fully Automatic Kaiping Production LineOct . 17, 2024

Fully Automatic Kaiping Production LineOct . 17, 2024 -

Fully Automatic Metal Bucket Lifting HeadphonesSep . 14, 2024

Fully Automatic Metal Bucket Lifting HeadphonesSep . 14, 2024