-

8613931787312

8613931787312 -

Botou Industrial Zone on the east side of National Highway 104, Botou City, Hebei Province

Botou Industrial Zone on the east side of National Highway 104, Botou City, Hebei Province

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- haitian_creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- scottish-gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

జన . 13, 2025 09:35

Back to list

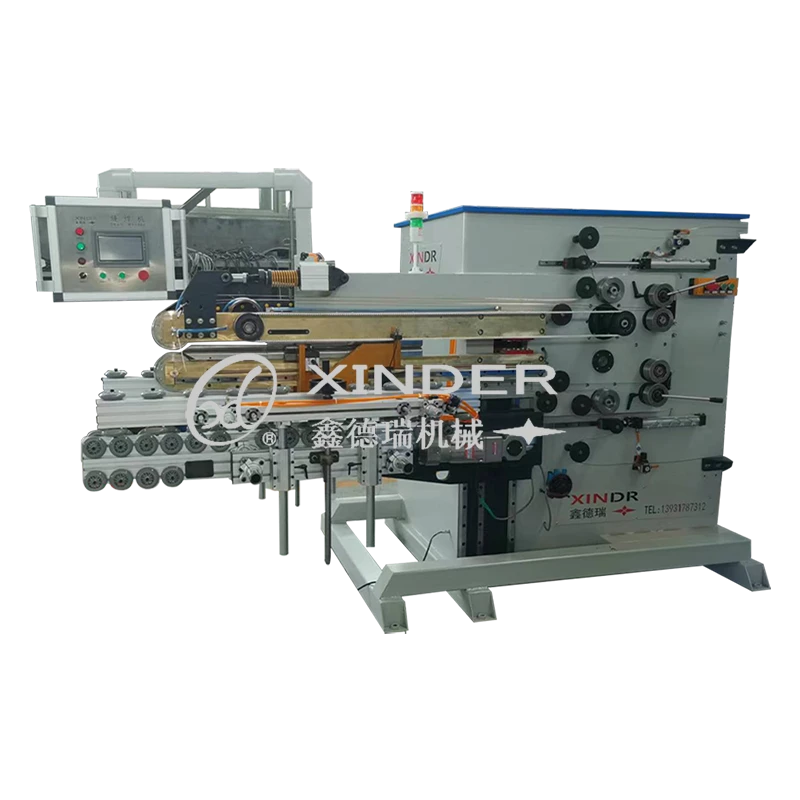

Small Can Seam Welding Machine

Unlock the full potential of precision and efficiency with the 150-watt laser welder—a standout in the realm of advanced welding technology. Having delved deep into the sphere of laser welding, my experience and continuous research confirm that investing in a 150-watt laser welder can significantly revolutionize industries like jewelry, automotive, and aerospace manufacturing.

From a technical standpoint, the 150-watt laser welder's ability to provide repeatable welds with minimal setup time is crucial for efficiency. The interface is generally user-friendly, providing step-by-step controls and real-time adjustments which enhance user confidence, whatever their experience level might be. This is particularly beneficial in high-volume production settings, where time is of the essence and accuracy can spell the difference between success and failure. When it comes to expertise, professionals need to understand that this equipment opens the door to innovation in material joining. The laser technology inherently allows for a cleaner welding environment by reducing the amount of consumables and minimizing the generation of waste material. This aligns well with modern manufacturing's push towards sustainability. In terms of trustworthiness and authority, manufacturers of the 150-watt laser welder provide extensive training and support, which helps professionals develop comprehensive expertise in utilizing the equipment to its full potential. Their offerings underscore a commitment to quality and innovation, furthering trust with end-users. Long hours of rigorous testing and adherence to international safety standards ensure that these machines not only deliver on their promises but exceed expectations, time and again. Ultimately, the integration of a 150-watt laser welder into your production processes can transform how you approach material joining. It’s a tool that embodies precision, power, and reliability, providing users with a multitude of applications across various industries. As leading experts in various fields have acknowledged through empirical evidence and continuous testing, the adoption of this technology is not a mere upgrade—it's a paradigm shift in achieving superior manufacturing outcomes.

From a technical standpoint, the 150-watt laser welder's ability to provide repeatable welds with minimal setup time is crucial for efficiency. The interface is generally user-friendly, providing step-by-step controls and real-time adjustments which enhance user confidence, whatever their experience level might be. This is particularly beneficial in high-volume production settings, where time is of the essence and accuracy can spell the difference between success and failure. When it comes to expertise, professionals need to understand that this equipment opens the door to innovation in material joining. The laser technology inherently allows for a cleaner welding environment by reducing the amount of consumables and minimizing the generation of waste material. This aligns well with modern manufacturing's push towards sustainability. In terms of trustworthiness and authority, manufacturers of the 150-watt laser welder provide extensive training and support, which helps professionals develop comprehensive expertise in utilizing the equipment to its full potential. Their offerings underscore a commitment to quality and innovation, furthering trust with end-users. Long hours of rigorous testing and adherence to international safety standards ensure that these machines not only deliver on their promises but exceed expectations, time and again. Ultimately, the integration of a 150-watt laser welder into your production processes can transform how you approach material joining. It’s a tool that embodies precision, power, and reliability, providing users with a multitude of applications across various industries. As leading experts in various fields have acknowledged through empirical evidence and continuous testing, the adoption of this technology is not a mere upgrade—it's a paradigm shift in achieving superior manufacturing outcomes.

Latest News

-

Understanding Seam Welding Technology: Applications and Equipment OverviewNewsAug.15,2025

-

The Rise of Automation in Welding: Enhancing Precision and ProductivityNewsAug.15,2025

-

The Applications and Importance of Laser Welding in Modern ManufacturingNewsAug.15,2025

-

Revolutionizing Industrial Welding with Automatic Seam Welding TechnologyNewsAug.15,2025

-

Precision and Efficiency in Metal Packaging: The Role of Can Welding MachinesNewsAug.15,2025

-

Advancing Metal Joining Technologies with Laser Welding and Soldering SolutionsNewsAug.15,2025

-

The Rise of Laser Welding: Precision Meets Power in Modern MetalworkNewsAug.06,2025

related products

-

Pneumatic Handle Welding MachineSep . 13, 2024

Pneumatic Handle Welding MachineSep . 13, 2024 -

Fully Automatic Kaiping Production LineOct . 17, 2024

Fully Automatic Kaiping Production LineOct . 17, 2024 -

Fully Automatic Metal Bucket Lifting HeadphonesSep . 14, 2024

Fully Automatic Metal Bucket Lifting HeadphonesSep . 14, 2024