-

8613931787312

8613931787312 -

Botou Industrial Zone on the east side of National Highway 104, Botou City, Hebei Province

Botou Industrial Zone on the east side of National Highway 104, Botou City, Hebei Province

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- haitian_creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- scottish-gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Januari . 14, 2025 11:12

Back to list

Hydraulic Bending Machine

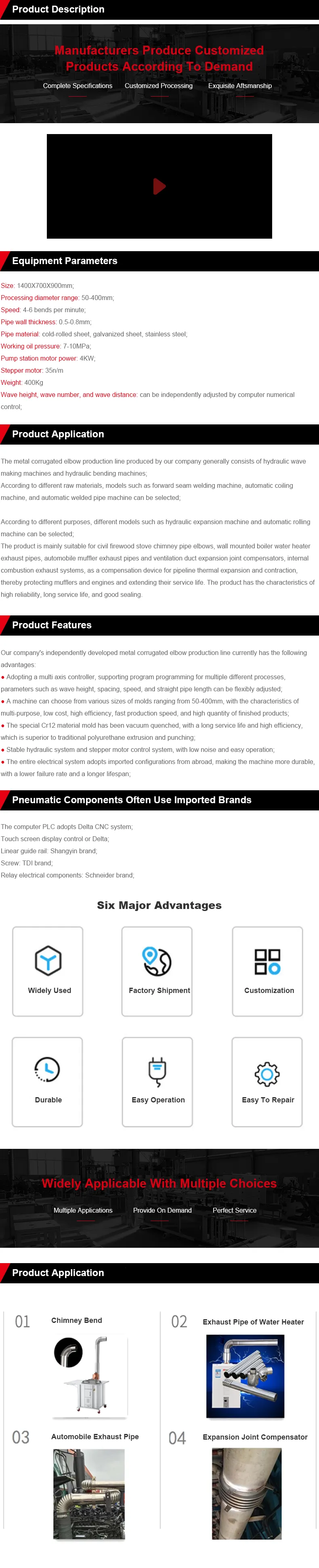

Rolling pipe bending machines have revolutionized the process of shaping metal pipes in industrial applications. These machines play a pivotal role in sectors ranging from automotive to aerospace due to their precision, efficiency, and versatility. With over a decade of industry experience, I've witnessed firsthand how the integration of rolling pipe bending machines can significantly enhance production capabilities.

Trust in rolling pipe bending machines is further cemented by the rigorous testing and quality assurance protocols they undergo before reaching the market. Manufacturers adhere to international standards, reflecting a commitment to safety and reliability. This dedication serves to foster confidence among users, knowing that each machine is not only a tool but a carefully engineered piece of equipment designed to deliver consistent results. Users of rolling pipe bending machines report a marked improvement in workflow, noting that these machines streamline operations and reduce manual labor. As a testament to their reliability and efficiency, companies often observe a measurable return on investment shortly after implementation. The machines' ability to handle a variety of pipe sizes and materials also adds to their versatility, making them a worthy addition to any manufacturing setup aiming for innovation and growth. In summary, rolling pipe bending machines are essential for any industry where precision and efficiency are paramount. Drawing from extensive experience and backed by industry expertise, these machines uphold the highest standards of production through their advanced technical features and adherence to quality assurance. Their authority in the field is unquestionable, fostering trust and setting the benchmark for metal pipe bending solutions worldwide.

Trust in rolling pipe bending machines is further cemented by the rigorous testing and quality assurance protocols they undergo before reaching the market. Manufacturers adhere to international standards, reflecting a commitment to safety and reliability. This dedication serves to foster confidence among users, knowing that each machine is not only a tool but a carefully engineered piece of equipment designed to deliver consistent results. Users of rolling pipe bending machines report a marked improvement in workflow, noting that these machines streamline operations and reduce manual labor. As a testament to their reliability and efficiency, companies often observe a measurable return on investment shortly after implementation. The machines' ability to handle a variety of pipe sizes and materials also adds to their versatility, making them a worthy addition to any manufacturing setup aiming for innovation and growth. In summary, rolling pipe bending machines are essential for any industry where precision and efficiency are paramount. Drawing from extensive experience and backed by industry expertise, these machines uphold the highest standards of production through their advanced technical features and adherence to quality assurance. Their authority in the field is unquestionable, fostering trust and setting the benchmark for metal pipe bending solutions worldwide.

Latest News

-

Understanding Resistance Welding: Equipment, Manufacturers, and PricingNewsMay.15,2025

-

Understanding Pneumatic Welding Machines: Types, Applications, and AdvantagesNewsMay.15,2025

-

Exploring Tube Benders: Types, Manufacturers, and ApplicationsNewsMay.15,2025

-

Exploring Metal Pipe Machines: Types, Functions, and ApplicationsNewsMay.15,2025

-

Exploring Laser Welding Machines: Key Manufacturers, Technology, and ApplicationsNewsMay.15,2025

-

Exploring Barrel Production Lines: Machines, Pricing, and Manufacturing ProcessNewsMay.15,2025

-

The Role of Steel Pipe Manufacturing Machines in Modern IndustriesNewsApr.18,2025

related products

-

Fully Automatic Kaiping Production LineOct . 17, 2024

Fully Automatic Kaiping Production LineOct . 17, 2024 -

Fully Automatic Metal Bucket Lifting HeadphonesSep . 14, 2024

Fully Automatic Metal Bucket Lifting HeadphonesSep . 14, 2024 -

Automatic Rolling MachineSep . 14, 2024

Automatic Rolling MachineSep . 14, 2024