-

8613931787312

8613931787312 -

Botou Industrial Zone on the east side of National Highway 104, Botou City, Hebei Province

Botou Industrial Zone on the east side of National Highway 104, Botou City, Hebei Province

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- haitian_creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- scottish-gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

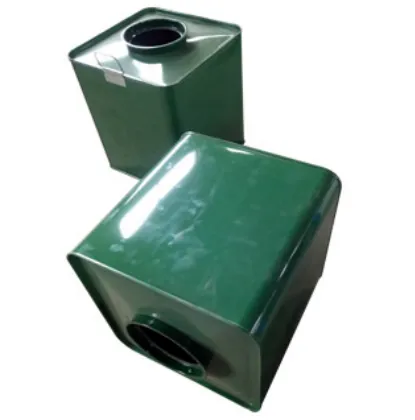

round pipe welding machine

The Advancements in Round Pipe Welding Machines

Welding is a critical process in various industries, including construction, manufacturing, and automotive sectors. Among the many types of welding equipment available, round pipe welding machines have carved out a significant niche due to their efficiency and precision in joining cylindrical components. This article explores the mechanics, advancements, applications, and future of round pipe welding machines.

Understanding Round Pipe Welding Machines

Round pipe welding machines are specialized tools designed to weld pipes that are cylindrical in shape. They can handle a variety of pipe materials including steel, stainless steel, and aluminum. The primary purpose of these machines is to create strong, leak-proof joints between pipe segments, which are essential in diverse applications like oil and gas pipelines, water transportation systems, and structural frameworks.

Mechanisms of Round Pipe Welding

There are several types of welding processes employed by round pipe welding machines, including

1. TIG (Tungsten Inert Gas) Welding This method uses a non-consumable tungsten electrode to produce the weld. It offers high control over the heat input, making it suitable for thin-walled pipes.

2. MIG (Metal Inert Gas) Welding MIG welding uses a continuous wire feed as an electrode and an inert gas to shield the weld from contamination. It is faster than TIG welding and ideal for thicker pipes.

3. Submerged Arc Welding (SAW) This process involves forming an arc between the base material and a continuously fed electrode, submerged under a granular flux. It is efficient for high-volume production and large-diameter pipes.

4. Orbital Welding This is an automatic welding process particularly good for precise and repetitive welding tasks. Machines can rotate around the pipe, ensuring uniform heat and high-quality welds.

Advancements in Technology

round pipe welding machine

Recent advancements in technology have significantly improved round pipe welding machines. One of the most notable is the integration of automation and robotics. Automated machines can execute tasks with high precision, reducing human error and improving throughput.

Moreover, the introduction of advanced software systems allows for better quality control and real-time monitoring of the welding process. These systems can adjust parameters such as speed, heat input, and material types on-the-fly, optimizing the weld quality while maintaining production efficiency.

Another significant advancement is the development of portable welding machines, which are increasingly being used on job sites. These machines maintain high performance while being lightweight and easy to transport, making them ideal for construction projects that require on-site welding.

Applications of Round Pipe Welding Machines

Round pipe welding machines find applications in various industries. In the energy sector, they are essential for constructing pipelines that transport oil and natural gas, ensuring structural integrity and safety. In the manufacturing industry, these machines play a crucial role in producing equipment and machinery components that require high-strength joints.

Other industries that benefit from round pipe welding machines include

- Water Treatment and Distribution For building water supply pipelines. - HVAC For fabricating ductwork and piping systems. - Shipbuilding For joining hull sections and piping systems.

The Future of Round Pipe Welding Machines

The future of round pipe welding machines looks promising with continuous innovations on the horizon. The rise of Industry 4.0 and smart manufacturing means that welding machines will increasingly incorporate artificial intelligence, data analytics, and IoT (Internet of Things) technologies. This could lead to predictive maintenance, where machines self-monitor their components to forecast and prevent failures before they occur.

Additionally, advancements in material science may pave the way for the use of new, lightweight, and high-strength materials, further pushing the capabilities of welding machines.

In conclusion, round pipe welding machines are vital tools in modern manufacturing and construction industries. With ongoing technological advancements, they are likely to become even more efficient, precise, and adaptable, ensuring that they remain indispensable in the face of evolving industry requirements. As industries strive for greater efficiency and sustainability, investing in advanced round pipe welding technology will be essential to meet these demands and drive future growth.

-

The Rise of Laser Welding: Precision Meets Power in Modern MetalworkNewsAug.06,2025

-

Streamlining Industrial Packaging: The Power of Barrel Production LinesNewsAug.06,2025

-

Revolutionizing Metal Joining: The Power of Automatic Seam Welding MachinesNewsAug.06,2025

-

Powering Industrial Innovation: The Role of Pipe and Tube Machinery in Modern ManufacturingNewsAug.06,2025

-

Exploring the World of Resistance Welding: Equipment, Manufacturers, and Pricing InsightsNewsAug.06,2025

-

Advancing Container Manufacturing: The Role of the Modern Can Welding MachineNewsAug.06,2025

-

Understanding Automatic Seam Welding Machines: A Game Changer in Welding TechnologyNewsJul.18,2025

-

Pneumatic Handle Welding MachineSep . 13, 2024

Pneumatic Handle Welding MachineSep . 13, 2024 -

Fully Automatic Kaiping Production LineOct . 17, 2024

Fully Automatic Kaiping Production LineOct . 17, 2024 -

Fully Automatic Metal Bucket Lifting HeadphonesSep . 14, 2024

Fully Automatic Metal Bucket Lifting HeadphonesSep . 14, 2024