-

8613931787312

8613931787312 -

Botou Industrial Zone on the east side of National Highway 104, Botou City, Hebei Province

Botou Industrial Zone on the east side of National Highway 104, Botou City, Hebei Province

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- haitian_creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- scottish-gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

sty . 23, 2025 05:50

Back to list

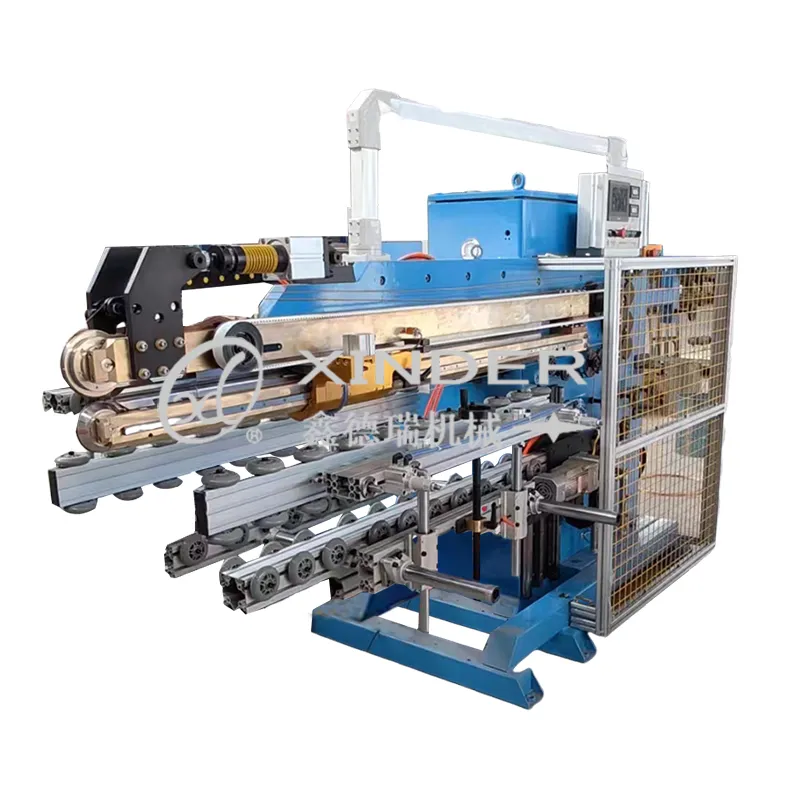

Export 100-200 Liter Large Steel Drums With Fully Automatic Welding Machine

Stainless steel barrels have become an integral part of various industries, offering durability, reliability, and versatility. These barrels are widely used in industries like food and beverage, pharmaceuticals, chemicals, and even the aging processes in the wine and spirits sector. The reasons behind their widespread application are several, stemming from their material properties and the technological advancements they represent.

For the experienced professional involved in logistics and supply chain management, stainless steel barrels offer unparalleled reliability. Their durability reduces the logistic costs and risks associated with frequent replacements and potential transportation damages. Additionally, they are recyclable, which aligns with the sustainability goals of many modern businesses. Companies can also reduce their carbon footprint by opting for stainless steel barrels, which reduces waste and supports circular economy initiatives. To invest in stainless steel barrels is to invest in a future-ready solution. As global industries shift towards more sustainable practices, the demand for long-lasting, non-reactive storage solutions will only grow. For businesses considering this upgrade, the initial investment may seem high, but the return on investment through longevity, reduced spoilage, and compliance with regulatory standards proves substantial. Selecting the right stainless steel barrel requires attention to specific details like the barrel type, such as open or closed head, the specific grade of stainless steel used (such as 304 or 316, with 316 offering greater resistance to corrosion), and understanding the finishes, like polished or brushed. A polished finish can provide additional sanitary benefits essential in food and pharmaceutical industries. Moreover, innovation in the design of these barrels continually evolves, with manufacturers improving features such as ease of mobility and stackability, increasing their utility in various applications. Experts in engineering and material sciences continue to research ways to enhance the efficiency and resilience of stainless steel barrels. This ongoing commitment to technological and methodical advancement assures that stainless steel remains at the forefront of industrial and commercial storage solutions. Trust in these barrels comes not just from their proven track record, but from a continued evolution meeting the ever-changing demands of industries worldwide. By understanding these significant advantages and recognizing their application-specific benefits, businesses and professionals can make informed decisions, ensuring operational excellence and sustainability.

For the experienced professional involved in logistics and supply chain management, stainless steel barrels offer unparalleled reliability. Their durability reduces the logistic costs and risks associated with frequent replacements and potential transportation damages. Additionally, they are recyclable, which aligns with the sustainability goals of many modern businesses. Companies can also reduce their carbon footprint by opting for stainless steel barrels, which reduces waste and supports circular economy initiatives. To invest in stainless steel barrels is to invest in a future-ready solution. As global industries shift towards more sustainable practices, the demand for long-lasting, non-reactive storage solutions will only grow. For businesses considering this upgrade, the initial investment may seem high, but the return on investment through longevity, reduced spoilage, and compliance with regulatory standards proves substantial. Selecting the right stainless steel barrel requires attention to specific details like the barrel type, such as open or closed head, the specific grade of stainless steel used (such as 304 or 316, with 316 offering greater resistance to corrosion), and understanding the finishes, like polished or brushed. A polished finish can provide additional sanitary benefits essential in food and pharmaceutical industries. Moreover, innovation in the design of these barrels continually evolves, with manufacturers improving features such as ease of mobility and stackability, increasing their utility in various applications. Experts in engineering and material sciences continue to research ways to enhance the efficiency and resilience of stainless steel barrels. This ongoing commitment to technological and methodical advancement assures that stainless steel remains at the forefront of industrial and commercial storage solutions. Trust in these barrels comes not just from their proven track record, but from a continued evolution meeting the ever-changing demands of industries worldwide. By understanding these significant advantages and recognizing their application-specific benefits, businesses and professionals can make informed decisions, ensuring operational excellence and sustainability.

Prev:

Latest News

-

Understanding Resistance Welding: Equipment, Manufacturers, and PricingNewsMay.15,2025

-

Understanding Pneumatic Welding Machines: Types, Applications, and AdvantagesNewsMay.15,2025

-

Exploring Tube Benders: Types, Manufacturers, and ApplicationsNewsMay.15,2025

-

Exploring Metal Pipe Machines: Types, Functions, and ApplicationsNewsMay.15,2025

-

Exploring Laser Welding Machines: Key Manufacturers, Technology, and ApplicationsNewsMay.15,2025

-

Exploring Barrel Production Lines: Machines, Pricing, and Manufacturing ProcessNewsMay.15,2025

-

The Role of Steel Pipe Manufacturing Machines in Modern IndustriesNewsApr.18,2025

related products

-

Fully Automatic Kaiping Production LineOct . 17, 2024

Fully Automatic Kaiping Production LineOct . 17, 2024 -

Fully Automatic Metal Bucket Lifting HeadphonesSep . 14, 2024

Fully Automatic Metal Bucket Lifting HeadphonesSep . 14, 2024 -

Automatic Rolling MachineSep . 14, 2024

Automatic Rolling MachineSep . 14, 2024