-

8613931787312

8613931787312 -

Botou Industrial Zone on the east side of National Highway 104, Botou City, Hebei Province

Botou Industrial Zone on the east side of National Highway 104, Botou City, Hebei Province

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- haitian_creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- scottish-gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

lut . 17, 2025 18:12

Back to list

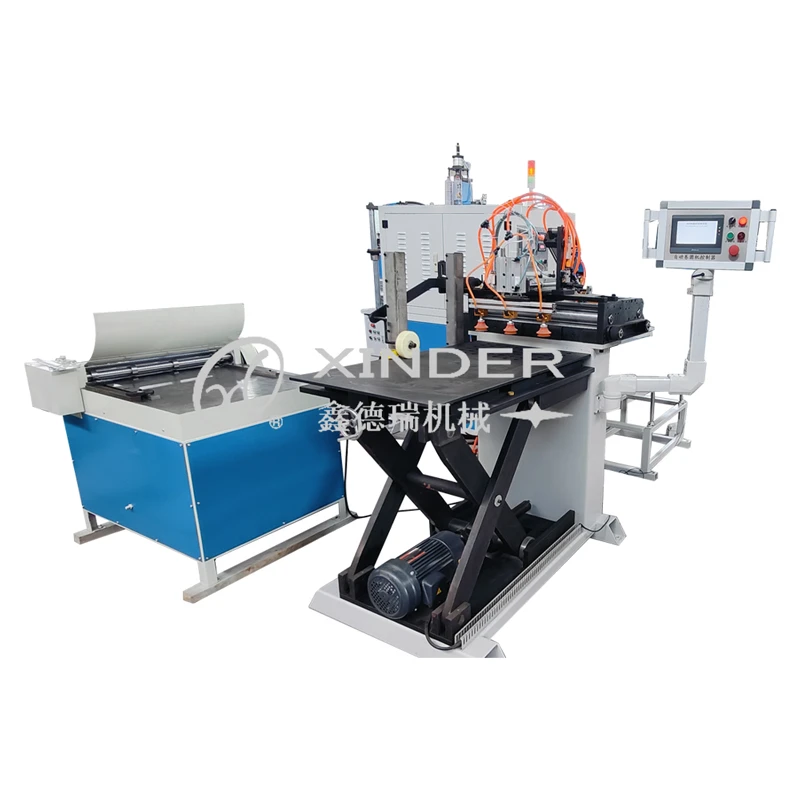

spiral elbow machine

When selecting equipment for constructing efficient and reliable duct systems in industrial or commercial settings, the spiral elbow machine stands out as an indispensable tool. This specialized machinery is designed to create spiral elbows, a critical component used in various heating, ventilation, and air conditioning (HVAC) systems due to their aerodynamic design and superior performance in air handling applications.

In terms of trustworthiness, operators and businesses that invest in spiral elbow machines gain a competitive advantage by being able to deliver projects on time and within budget. The reliability of the machine minimizes downtime, often a costly issue in fabrication settings. Furthermore, once set up, these machines require minimal human intervention, reducing the chance of error that can occur with manual methods. Regular maintenance and updates ensure longevity and sustained performance, making it a trusted choice for long-term planning. From a product category perspective, the spiral elbow machine features several configurations and options to suit varying production needs. These include manual, semi-automatic, and fully automated models, each catering to a different scale of production and budget. Advanced models come with enhanced cutting systems, adjustable forming heads, and automatic coil feeding, which accommodate high-volume demands and intricate design requirements. For companies looking to enhance their production capabilities, investing in a spiral elbow machine is a wise decision. Not only does it allow for improved operational efficiency and product quality, but it also positions businesses to meet the growing demand for high-performance duct systems. With robust after-sales support and comprehensive training programs available from manufacturers, operators can feel confident in their ability to utilize these machines to their full potential. In conclusion, the spiral elbow machine embodies a blend of experience, expertise, authoritativeness, and trustworthiness that is essential for the modern HVAC industry. Its role in producing superior products that aid in the efficient movement and control of air is critical to the functionality of complex mechanical systems in various buildings. As the industry continues to evolve, these machines will remain at the forefront of innovation, offering solutions that meet the demands of both today and the future. The investment in such technology pays off not only in immediate productivity gains but also in the long-term reliability and satisfaction of end clients.

In terms of trustworthiness, operators and businesses that invest in spiral elbow machines gain a competitive advantage by being able to deliver projects on time and within budget. The reliability of the machine minimizes downtime, often a costly issue in fabrication settings. Furthermore, once set up, these machines require minimal human intervention, reducing the chance of error that can occur with manual methods. Regular maintenance and updates ensure longevity and sustained performance, making it a trusted choice for long-term planning. From a product category perspective, the spiral elbow machine features several configurations and options to suit varying production needs. These include manual, semi-automatic, and fully automated models, each catering to a different scale of production and budget. Advanced models come with enhanced cutting systems, adjustable forming heads, and automatic coil feeding, which accommodate high-volume demands and intricate design requirements. For companies looking to enhance their production capabilities, investing in a spiral elbow machine is a wise decision. Not only does it allow for improved operational efficiency and product quality, but it also positions businesses to meet the growing demand for high-performance duct systems. With robust after-sales support and comprehensive training programs available from manufacturers, operators can feel confident in their ability to utilize these machines to their full potential. In conclusion, the spiral elbow machine embodies a blend of experience, expertise, authoritativeness, and trustworthiness that is essential for the modern HVAC industry. Its role in producing superior products that aid in the efficient movement and control of air is critical to the functionality of complex mechanical systems in various buildings. As the industry continues to evolve, these machines will remain at the forefront of innovation, offering solutions that meet the demands of both today and the future. The investment in such technology pays off not only in immediate productivity gains but also in the long-term reliability and satisfaction of end clients.

Prev:

Next:

Latest News

-

The Rise of Laser Welding: Precision Meets Power in Modern MetalworkNewsAug.06,2025

-

Streamlining Industrial Packaging: The Power of Barrel Production LinesNewsAug.06,2025

-

Revolutionizing Metal Joining: The Power of Automatic Seam Welding MachinesNewsAug.06,2025

-

Powering Industrial Innovation: The Role of Pipe and Tube Machinery in Modern ManufacturingNewsAug.06,2025

-

Exploring the World of Resistance Welding: Equipment, Manufacturers, and Pricing InsightsNewsAug.06,2025

-

Advancing Container Manufacturing: The Role of the Modern Can Welding MachineNewsAug.06,2025

-

Understanding Automatic Seam Welding Machines: A Game Changer in Welding TechnologyNewsJul.18,2025

related products

-

Pneumatic Handle Welding MachineSep . 13, 2024

Pneumatic Handle Welding MachineSep . 13, 2024 -

Fully Automatic Kaiping Production LineOct . 17, 2024

Fully Automatic Kaiping Production LineOct . 17, 2024 -

Fully Automatic Metal Bucket Lifting HeadphonesSep . 14, 2024

Fully Automatic Metal Bucket Lifting HeadphonesSep . 14, 2024