-

8613931787312

8613931787312 -

Botou Industrial Zone on the east side of National Highway 104, Botou City, Hebei Province

Botou Industrial Zone on the east side of National Highway 104, Botou City, Hebei Province

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- haitian_creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- scottish-gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

ਜਨਃ . 14, 2025 16:45

Back to list

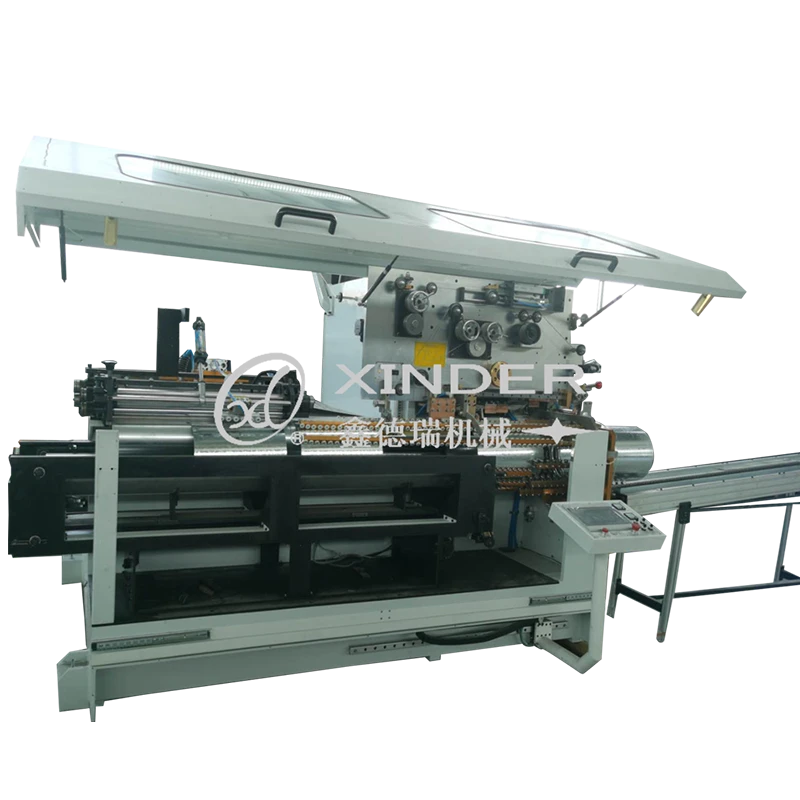

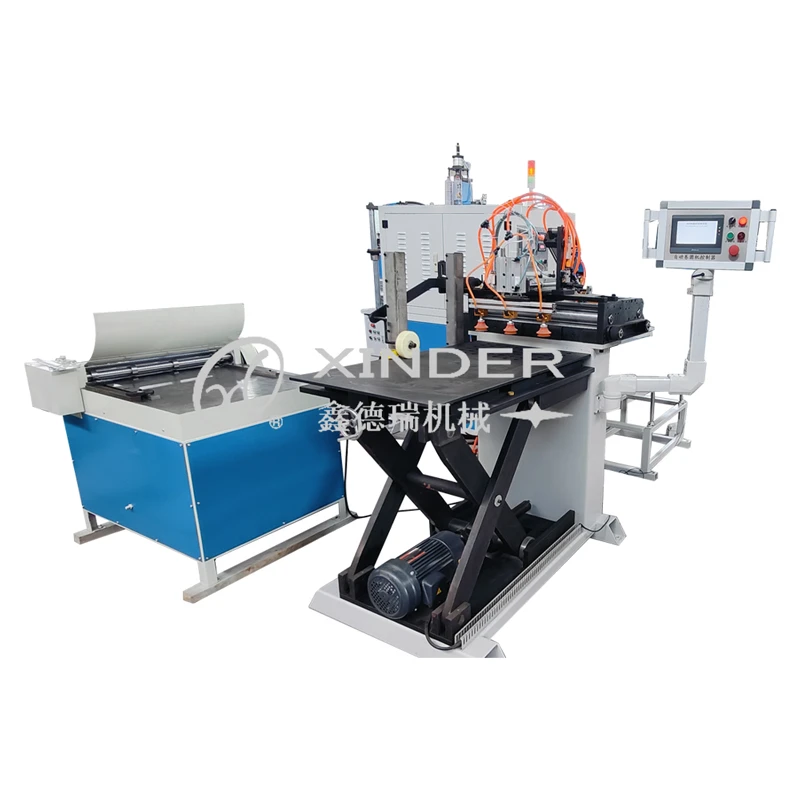

Small Can Seam Welding Machine

Navigating the intricate world of CNC laser welders can feel like a daunting task, especially when you're in search of a machine that seamlessly combines precision, efficiency, and reliability. From personal experience, choosing the right CNC laser welder boils down to understanding the specific needs of your project and the qualities that define a superior machine.

CNC laser welders also enhance business operations due to their scalability. Modern models often come with automation capabilities that allow for integration with robotics or customized conveyor systems. These machines can be pivotal in ramping up production, maintaining consistency in output, and ensuring that deadlines are met without compromising on quality. However, expertise in operating these sophisticated machines cannot be understated. Training and safety protocols must be integral to the operational planning for any shop floor. While manufacturers often provide basic training and user manuals, investing in comprehensive training programs will ensure operators are proficient in using the equipment safely and to its fullest potential, thereby fostering a culture of trust and accountability within the workforce. Real-world application and industry reviews further solidify the standing of CNC laser welders within the fabricating community. Discussions with seasoned professionals reveal that the optimal utility derives not just from the machine's features but also its maintenance regime. Regular upkeep and leveraging manufacturer support services positively impact machine longevity and performance, forming an essential part of operational strategy. In conclusion, investing in a CNC laser welder that marries precision with versatility not only enhances production capabilities but also serves as a strategic business asset. The seamless integration of innovation and expertise epitomizes the true essence of these remarkable machines, setting a new benchmark for excellence in the welding industry.

CNC laser welders also enhance business operations due to their scalability. Modern models often come with automation capabilities that allow for integration with robotics or customized conveyor systems. These machines can be pivotal in ramping up production, maintaining consistency in output, and ensuring that deadlines are met without compromising on quality. However, expertise in operating these sophisticated machines cannot be understated. Training and safety protocols must be integral to the operational planning for any shop floor. While manufacturers often provide basic training and user manuals, investing in comprehensive training programs will ensure operators are proficient in using the equipment safely and to its fullest potential, thereby fostering a culture of trust and accountability within the workforce. Real-world application and industry reviews further solidify the standing of CNC laser welders within the fabricating community. Discussions with seasoned professionals reveal that the optimal utility derives not just from the machine's features but also its maintenance regime. Regular upkeep and leveraging manufacturer support services positively impact machine longevity and performance, forming an essential part of operational strategy. In conclusion, investing in a CNC laser welder that marries precision with versatility not only enhances production capabilities but also serves as a strategic business asset. The seamless integration of innovation and expertise epitomizes the true essence of these remarkable machines, setting a new benchmark for excellence in the welding industry.

Latest News

-

Understanding Seam Welding Technology: Applications and Equipment OverviewNewsAug.15,2025

-

The Rise of Automation in Welding: Enhancing Precision and ProductivityNewsAug.15,2025

-

The Applications and Importance of Laser Welding in Modern ManufacturingNewsAug.15,2025

-

Revolutionizing Industrial Welding with Automatic Seam Welding TechnologyNewsAug.15,2025

-

Precision and Efficiency in Metal Packaging: The Role of Can Welding MachinesNewsAug.15,2025

-

Advancing Metal Joining Technologies with Laser Welding and Soldering SolutionsNewsAug.15,2025

-

The Rise of Laser Welding: Precision Meets Power in Modern MetalworkNewsAug.06,2025

related products

-

Pneumatic Handle Welding MachineSep . 13, 2024

Pneumatic Handle Welding MachineSep . 13, 2024 -

Fully Automatic Kaiping Production LineOct . 17, 2024

Fully Automatic Kaiping Production LineOct . 17, 2024 -

Fully Automatic Metal Bucket Lifting HeadphonesSep . 14, 2024

Fully Automatic Metal Bucket Lifting HeadphonesSep . 14, 2024