-

8613931787312

8613931787312 -

Botou Industrial Zone on the east side of National Highway 104, Botou City, Hebei Province

Botou Industrial Zone on the east side of National Highway 104, Botou City, Hebei Province

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- haitian_creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- scottish-gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

ਜਨਃ . 16, 2025 05:32

Back to list

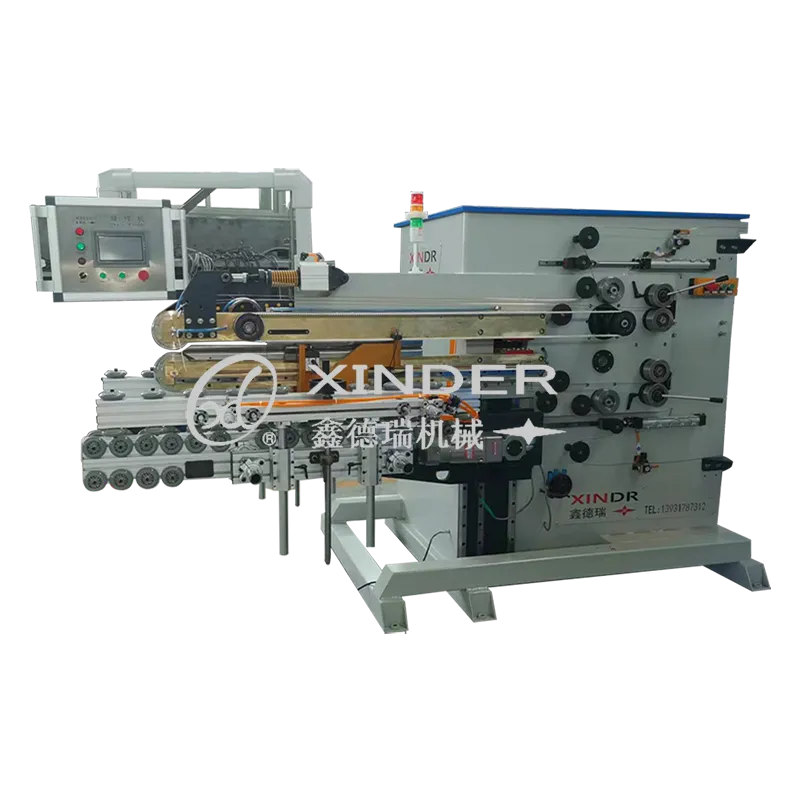

Fully Automatic Steel Barrel Straight Seam Laser Welding Machine

Discovering the advantages of air-cooled laser welding machines can significantly impact your manufacturing processes, offering a seamless, efficient, and cost-effective alternative to traditional welding methods. As laser technology evolves, understanding the intricacies of these machines becomes imperative for industries aiming to maximize precision and productivity.

Establishing trustworthiness in this field hinges on transparency and proven performance. Air-cooled laser welding machines have undergone rigorous testing to validate their effectiveness and efficiency across various applications. These machines are backed by extensive research and development, ensuring that they meet stringent industry standards and certifications. Manufacturers provide comprehensive data and real-world case studies that demonstrate the long-term benefits and savings achievable through the adoption of air-cooled laser technology, reinforcing confidence among potential buyers and users. In practice, air-cooled laser welding machines deliver exceptional user experience through easy-to-use interfaces and robust designs. Operators benefit from intuitive controls that simplify the setup and operation of the machine, reducing the learning curve and enhancing productivity. Furthermore, the maintenance-free aspect of air cooling means that technicians can focus more on production rather than dealing with the complications associated with fluid-based cooling systems. Additionally, air-cooled laser welding technology supports sustainability goals, a growing concern for industries worldwide. By eliminating the need for water and reducing energy consumption, these machines contribute to an eco-friendlier production environment. The reduction in maintenance requirements also means fewer resources are needed over the machine's lifespan, aligning with sustainable manufacturing practices aimed at reducing overall industrial footprints. Overall, the strategic adoption of air-cooled laser welding machines empowers industries with cutting-edge technology that combines efficiency, precision, and sustainability. As manufacturers continue to seek innovative solutions to enhance their production capabilities, the reliability and performance of air-cooled laser systems make them an invaluable asset within any forward-thinking organization. Whether enhancing current production lines or embarking on new manufacturing ventures, incorporating air-cooled laser welding technology can offer substantial, measurable benefits, ensuring a strong return on investment and a competitive edge in today's demanding market landscape.

Establishing trustworthiness in this field hinges on transparency and proven performance. Air-cooled laser welding machines have undergone rigorous testing to validate their effectiveness and efficiency across various applications. These machines are backed by extensive research and development, ensuring that they meet stringent industry standards and certifications. Manufacturers provide comprehensive data and real-world case studies that demonstrate the long-term benefits and savings achievable through the adoption of air-cooled laser technology, reinforcing confidence among potential buyers and users. In practice, air-cooled laser welding machines deliver exceptional user experience through easy-to-use interfaces and robust designs. Operators benefit from intuitive controls that simplify the setup and operation of the machine, reducing the learning curve and enhancing productivity. Furthermore, the maintenance-free aspect of air cooling means that technicians can focus more on production rather than dealing with the complications associated with fluid-based cooling systems. Additionally, air-cooled laser welding technology supports sustainability goals, a growing concern for industries worldwide. By eliminating the need for water and reducing energy consumption, these machines contribute to an eco-friendlier production environment. The reduction in maintenance requirements also means fewer resources are needed over the machine's lifespan, aligning with sustainable manufacturing practices aimed at reducing overall industrial footprints. Overall, the strategic adoption of air-cooled laser welding machines empowers industries with cutting-edge technology that combines efficiency, precision, and sustainability. As manufacturers continue to seek innovative solutions to enhance their production capabilities, the reliability and performance of air-cooled laser systems make them an invaluable asset within any forward-thinking organization. Whether enhancing current production lines or embarking on new manufacturing ventures, incorporating air-cooled laser welding technology can offer substantial, measurable benefits, ensuring a strong return on investment and a competitive edge in today's demanding market landscape.

Latest News

-

Understanding Seam Welding Technology: Applications and Equipment OverviewNewsAug.15,2025

-

The Rise of Automation in Welding: Enhancing Precision and ProductivityNewsAug.15,2025

-

The Applications and Importance of Laser Welding in Modern ManufacturingNewsAug.15,2025

-

Revolutionizing Industrial Welding with Automatic Seam Welding TechnologyNewsAug.15,2025

-

Precision and Efficiency in Metal Packaging: The Role of Can Welding MachinesNewsAug.15,2025

-

Advancing Metal Joining Technologies with Laser Welding and Soldering SolutionsNewsAug.15,2025

-

The Rise of Laser Welding: Precision Meets Power in Modern MetalworkNewsAug.06,2025

related products

-

Pneumatic Handle Welding MachineSep . 13, 2024

Pneumatic Handle Welding MachineSep . 13, 2024 -

Fully Automatic Kaiping Production LineOct . 17, 2024

Fully Automatic Kaiping Production LineOct . 17, 2024 -

Fully Automatic Metal Bucket Lifting HeadphonesSep . 14, 2024

Fully Automatic Metal Bucket Lifting HeadphonesSep . 14, 2024