-

8613931787312

8613931787312 -

Botou Industrial Zone on the east side of National Highway 104, Botou City, Hebei Province

Botou Industrial Zone on the east side of National Highway 104, Botou City, Hebei Province

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- haitian_creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- scottish-gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

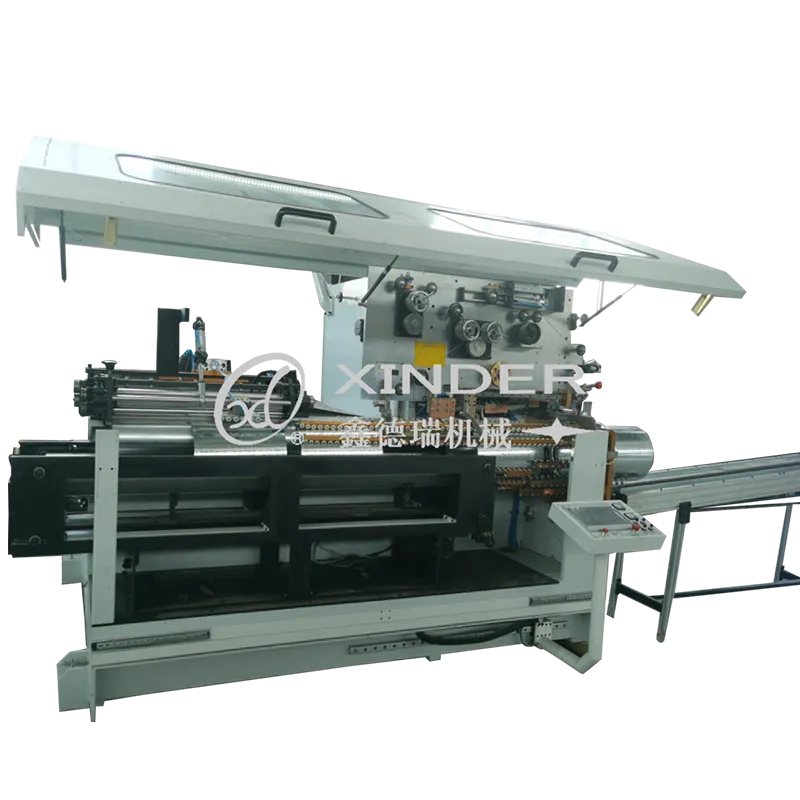

automatic acrylic bending machine

The Rise of Automatic Acrylic Bending Machines Revolutionizing the Fabrication Process

In the realm of manufacturing and fabrication, the demand for precision and efficiency has never been higher. Among the various materials that are widely utilized, acrylic stands out due to its versatility, lightweight nature, and optical clarity. However, one of the challenges with acrylic is the bending process, which requires careful handling to avoid cracking or breaking. Enter the automatic acrylic bending machine—a technological innovation that is transforming the way acrylic products are produced.

Understanding Acrylic Bending

Acrylic, commonly known as Plexiglass, is a thermoplastic material widely used in various applications, from signage and displays to furniture and protective barriers. The process of bending acrylic involves applying heat to the material until it becomes flexible, allowing manufacturers to shape it into desired forms. Traditionally, this process has been labor-intensive, relying heavily on manual skills and experience. However, as the demand grows for more complex designs and mass production, relying solely on manual bending techniques has become inefficient.

The Advantages of Automatic Acrylic Bending Machines

1. Precision and Consistency One of the primary benefits of automatic acrylic bending machines is their ability to deliver precise and consistent results. Unlike manual bending, where variances in technique can lead to inconsistencies, automatic machines utilize advanced technology—such as CNC (Computer Numerical Control)—to ensure each piece is bent to exact specifications. This precision reduces waste and increases overall efficiency.

2. Increased Productivity Automatic bending machines significantly boost productivity. While manual bending requires skilled labor and can only handle a limited volume of work on a daily basis, automated systems can operate continuously with minimal downtime. This means that manufacturers can meet large orders and tight deadlines without compromising quality.

3. Reduced Labor Costs With automation, the reliance on skilled labor decreases. Although initial investments in automatic bending machines can be substantial, the long-term savings in labor costs often offset these expenditures. Additionally, automation minimizes human error, thereby reducing the likelihood of costly mistakes during production.

automatic acrylic bending machine

4. Enhanced Design Capabilities Automatic acrylic bending machines can handle complex designs that might be challenging or impossible to achieve through manual methods. This capability broadens the horizons for designers and manufacturers, allowing for innovative applications that enhance their product offerings.

5. User-Friendly Interfaces Modern automatic bending machines are designed with user-friendly interfaces, making it simple for operators, even those with minimal technical expertise, to manage the bending process. Many machines come equipped with touchscreens and pre-programmed bending profiles, which streamline the setup and operation processes.

Applications Across Industries

The versatility of acrylic combined with the efficiency of automatic bending machines has led to their adoption across various industries. In the retail industry, businesses use acrylic displays and signage to attract customers; the ability to produce these pieces quickly and with precision is crucial for maintaining a competitive edge. Similarly, in the architecture and interior design sectors, acrylic is favored for its aesthetic appeal, and automatic bending machines can create complex shapes that might be necessary for unique design elements.

Additionally, the automotive and aerospace industries benefit from automatic acrylic bending machines for creating lightweight components that do not compromise structural integrity. As these industries continue to evolve, the ability to mass-produce customized parts will be invaluable.

Conclusion

The advent of automatic acrylic bending machines represents a significant advancement in the way acrylic products are manufactured. The combination of precision, increased productivity, and reduced labor costs makes these machines an essential asset for modern fabrication facilities. As technology continues to develop, we can expect further innovations in this field, pushing the boundaries of what is possible with acrylic and other materials. In an era where efficiency and creativity are paramount, the automatic acrylic bending machine stands out as a tool that not only simplifies the manufacturing process but also enhances the capability to meet consumer demands. Whether in retail, architecture, or manufacturing, these machines are set to play a pivotal role in shaping the future of production.

-

Understanding Automatic Seam Welding Machines: A Game Changer in Welding TechnologyNewsJul.18,2025

-

Revolutionizing Packaging: The Role of Welding Machines in Steel and Tin Can ManufacturingNewsJul.18,2025

-

Precision in Motion: Exploring Seam Welding Machines for Industrial FabricationNewsJul.18,2025

-

Mastering Precision Bending: A Guide to Tube Benders and Their TypesNewsJul.18,2025

-

Inside the World of Barrel Manufacturing: Machines, Lines, and CostsNewsJul.18,2025

-

Exploring the Technology Behind Elbow Bending Machines in Pipe ManufacturingNewsJul.18,2025

-

Unlocking the Power of Light: Exploring Modern Laser Welding SolutionsNewsJul.15,2025

-

Pneumatic Handle Welding MachineSep . 13, 2024

Pneumatic Handle Welding MachineSep . 13, 2024 -

Fully Automatic Kaiping Production LineOct . 17, 2024

Fully Automatic Kaiping Production LineOct . 17, 2024 -

Fully Automatic Metal Bucket Lifting HeadphonesSep . 14, 2024

Fully Automatic Metal Bucket Lifting HeadphonesSep . 14, 2024