-

8613931787312

8613931787312 -

Botou Industrial Zone on the east side of National Highway 104, Botou City, Hebei Province

Botou Industrial Zone on the east side of National Highway 104, Botou City, Hebei Province

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- haitian_creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- scottish-gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

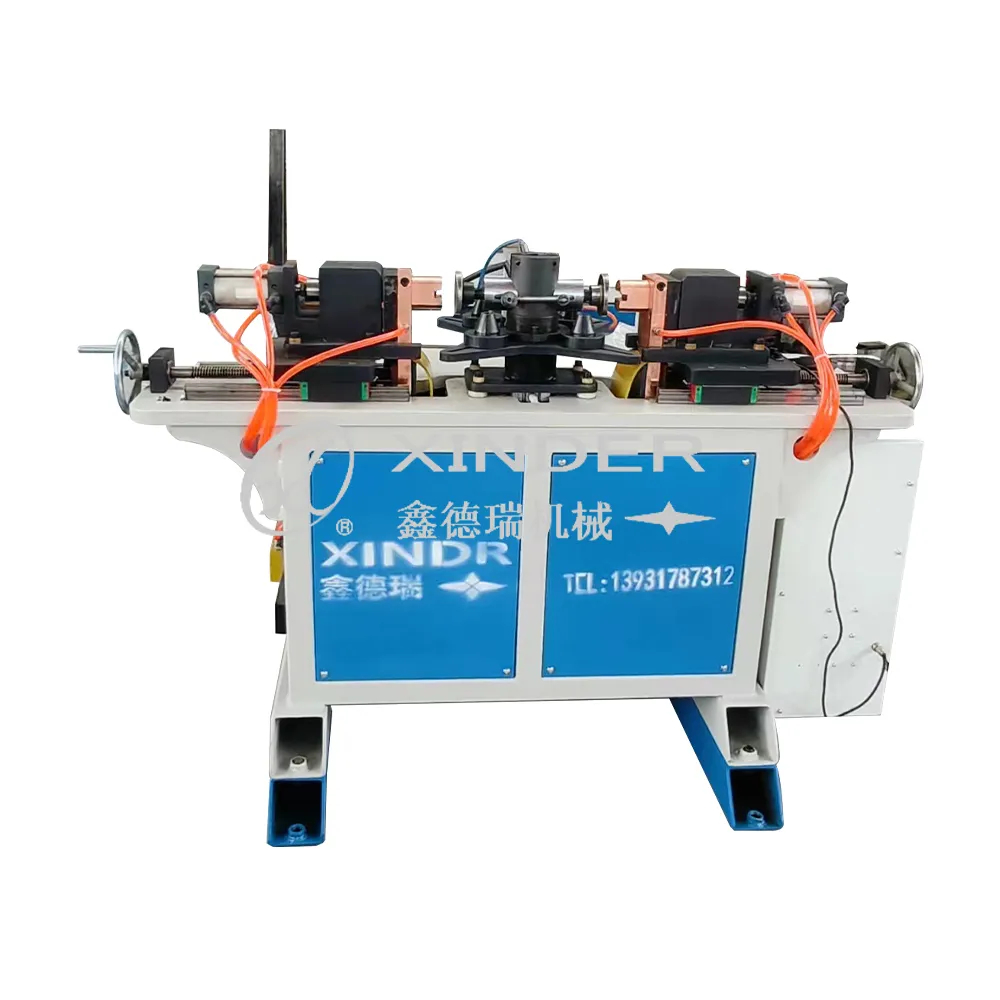

265-450mm MF Pneumatic Double Ear Spot Welder - Efficient & Precise

Hebei Xindrui Machinery Manufacturing Co., Ltd.

Botou Industrial Zone on the east side of National Highway 104, Botou City, Hebei Province

Technological Advancements in Spot Welding Systems

The manufacturing sector has witnessed remarkable progress in resistance welding technology over the past decade. Medium frequency (MFDC) welding systems represent a quantum leap from traditional AC welding machines, offering significantly improved control over the welding process. According to a study published in the Journal of Manufacturing Processes, MFDC technology increases energy efficiency by 30-40% compared to conventional AC systems while reducing thermal distortion in workpieces.

Revolutionizing Can Production

The specialized 265-450mm Medium Frequency Pneumatic Double Ear Spot Welding Machine has been engineered specifically for attaching lifting ears to can bodies. This sophisticated equipment welds both lifting ears simultaneously, ensuring perfect symmetry and structural integrity. Key advantages include:

- Simultaneous Dual-Ear Welding: Ensures consistent symmetry and structural balance

- Advanced Pneumatic Control: Imported components guarantee reliable operation

- High-Performance Electrodes: Alloy construction maximizes durability and longevity

- Precision Microcontroller: Digital circuits regulate current and action sequences

- Automatic Paint Breaking: Stable and efficient processing without blank spaces

Technical Specifications and Performance Metrics

The operational excellence of the 265-450mm Medium Frequency Pneumatic Double Ear Spot Welding Machine stems from its meticulously engineered specifications. Utilizing digital control systems and pneumatic precision, these machines deliver unmatched consistency in industrial settings.

| Parameter | Specification | Performance Benefit |

|---|---|---|

| Welding Diameter Range | 265-450mm | Versatility across can sizes |

| Welding Thickness | 0.4-1.2mm (steel) | Flexibility for different material grades |

| Power Supply | 380V ±10% 50/60Hz | Compatible with global standards |

| Rated Capacity | 120kVA | High-output performance |

| Air Consumption | 0.5-0.6MPa (0.6m³/min) | Energy-efficient operation |

| Welding Time | Adjustable 1-60 cycles | Precision process control |

| Frequency | 1kHz Medium Frequency | Better heat control, reduced spatter |

| Dimensions | 1500×850×1700mm | Compact footprint |

Dual-Ear Welding Precision

Simultaneous welding action of the 265-450mm Medium Frequency Pneumatic Double Ear Spot Welding Machine ensures perfect symmetry and structural balance

Advanced Control System

Microcontroller technology in the 265-450mm Medium Frequency Pneumatic Double Ear Spot Welding Machine provides exceptional process control

Industrial Applications and Material Compatibility

Precision welding machines serve critical functions across multiple industries. The specialized design of the 265-450mm Medium Frequency Pneumatic Double Ear Spot Welding Machine makes it particularly valuable in:

Packaging Industry Applications

Industrial can manufacturing demands precision joining of complex assemblies. Research by the International Journal of Advanced Manufacturing Technology indicates that specialized welding equipment can reduce rejection rates by up to 25% while increasing production speeds by 30%.

Material Compatibility and Electrode Technology

The welding system is engineered for compatibility with multiple material grades:

- Galvanized Steel: Primary application with thickness ranging from 0.4-1.2mm

- Cold Rolled Steel: Standard material for industrial container111s

- Special Alloys: Compatibility with specialized container111 requirements

Technical FAQ: Pneumatic Double Ear Spot Welding

MFDC technology enables faster rise times and superior control of current flow. According to the Resistance Welding Manufacturing Alliance, this results in 25-35% energy efficiency improvements and 40% reduction in electrode wear compared to AC systems. The inverter technology allows precise adjustment of welding parameters for different material combinations.

Daily lubrication of pneumatic cylinders and monthly inspection of valves is recommended. The system uses ISO 8573-1 Class 3 compressed air with moisture content below 80% relative humidity. Quarterly replacement of air filters ensures optimal performance of the dual-ear welding mechanism.

The system incorporates a two-stage welding process that first removes paint or coating at the contact point using a precisely controlled electrical discharge. This creates a clean metallic surface before the main welding current is applied, ensuring superior electrical contact and consistent weld quality across production batches.

The equipment meets CE safety requirements and ANSI/AWS C1.1M:2020 specifications for resistance welding. Weld quality verification follows ISO 14329:2003 standards for destructive testing of spot welds. Additional certifications ensure compliance with electrical safety directives for industrial machinery.

Electrode longevity primarily depends on material combination, required welding current, and workpiece thickness. Industry studies show that proper water cooling and force application can extend electrode life by 60-80%. Standard copper-chromium-zirconium alloys typically maintain peak performance for 15,000-25,000 welds before reconditioning is needed.

The installation requires a stable power supply with maximum 10% voltage fluctuation. Clean, dry compressed air at 0.5-0.6MPa is critical for consistent operation. Foundation specifications include vibration isolation pads and thermal management systems for heat dissipation. Environmental conditions should maintain temperatures between 5-40°C with relative humidity below 80%.

The digital control systems continuously monitor and adjust welding parameters using PID algorithms. Real-time feedback mechanisms regulate output to overcome resistance variations caused by surface contamination, electrode wear, or material inconsistencies. Modern systems achieve parametric consistency within ±1.5%, significantly reducing quality variability.

Industry Research and References

- "Advances in Medium Frequency Resistance Welding" - Journal of Materials Processing Technology: https://doi.org/10.1016/j.jmatprotec.2022.117123

- "Productivity Improvements in Container Manufacturing" - International Packaging Research Association: https://ipra.org/research/packaging-automation-2023/

- "Energy Efficiency in Industrial Welding Processes" - Manufacturing Technology Review: https://mtrjournal.com/volume-14/welding-energy-optimization/

- "Quality Control in Resistance Spot Welding" - American Welding Society Research Reports: https://app.aws.org/research/spot-welding-quality/

- "Automation Trends in Metal Fabrication" - Industrial Equipment News: https://www.ien.com/automation/article/22860595/metal-fabrication-automation-trends-2024

-

Understanding Automatic Seam Welding Machines: A Game Changer in Welding TechnologyNewsJul.18,2025

-

Revolutionizing Packaging: The Role of Welding Machines in Steel and Tin Can ManufacturingNewsJul.18,2025

-

Precision in Motion: Exploring Seam Welding Machines for Industrial FabricationNewsJul.18,2025

-

Mastering Precision Bending: A Guide to Tube Benders and Their TypesNewsJul.18,2025

-

Inside the World of Barrel Manufacturing: Machines, Lines, and CostsNewsJul.18,2025

-

Exploring the Technology Behind Elbow Bending Machines in Pipe ManufacturingNewsJul.18,2025

-

Unlocking the Power of Light: Exploring Modern Laser Welding SolutionsNewsJul.15,2025

-

Pneumatic Handle Welding MachineSep . 13, 2024

Pneumatic Handle Welding MachineSep . 13, 2024 -

Fully Automatic Kaiping Production LineOct . 17, 2024

Fully Automatic Kaiping Production LineOct . 17, 2024 -

Fully Automatic Metal Bucket Lifting HeadphonesSep . 14, 2024

Fully Automatic Metal Bucket Lifting HeadphonesSep . 14, 2024