-

8613931787312

8613931787312 -

Botou Industrial Zone on the east side of National Highway 104, Botou City, Hebei Province

Botou Industrial Zone on the east side of National Highway 104, Botou City, Hebei Province

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- haitian_creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- scottish-gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

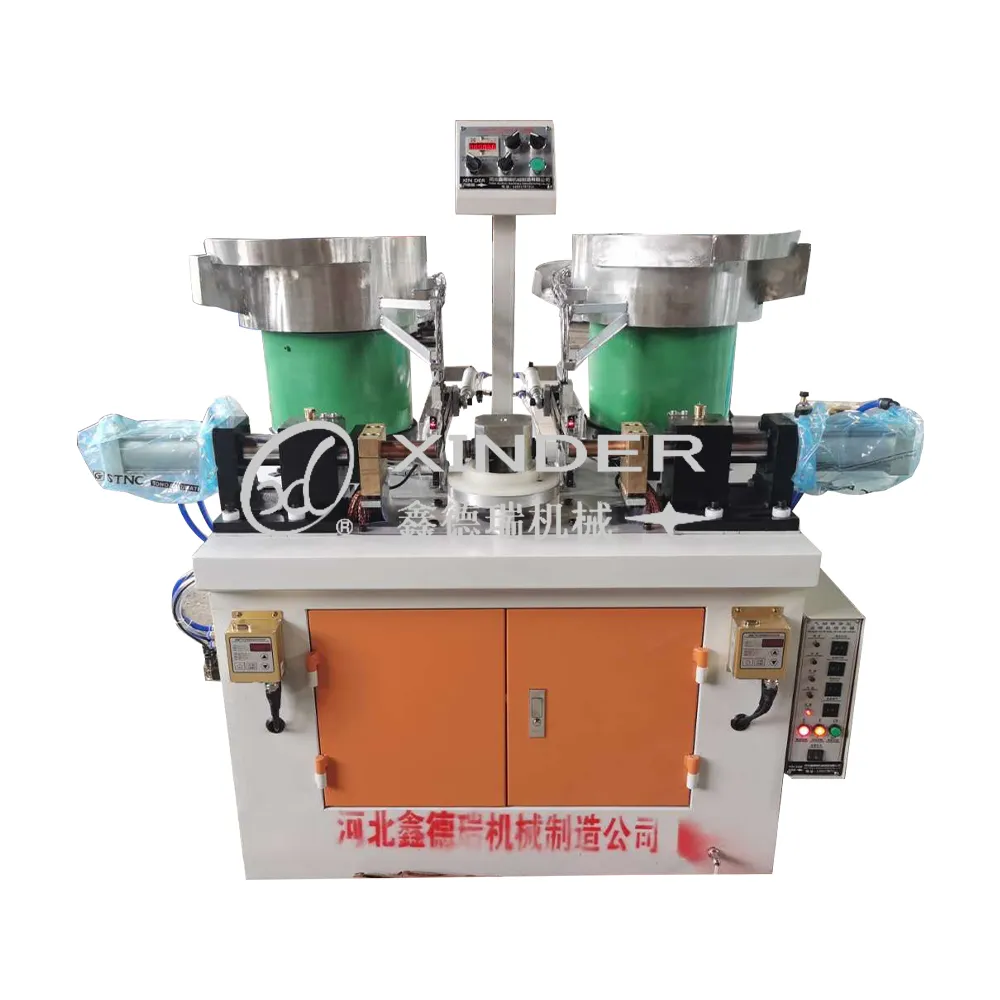

Pneumatic Spot Welder: Auto Precision Welding Machine

The Evolution of Precision Welding: Understanding the Pneumatic Spot Welder in Modern Manufacturing

In the dynamic landscape of industrial manufacturing, the demand for robust, efficient, and precise joining techniques has never been more critical. At the forefront of this evolution stands the pneumatic spot welder, a cornerstone technology that has revolutionized various production lines, particularly in sectors requiring high-volume, repetitive, and reliable metal joining. This technology, exemplified by sophisticated systems like the Fully automatic pneumatic double ear spot welding machine, leverages compressed air to apply controlled pressure to workpieces, facilitating resistance welding where localized heat generates a molten nugget at the interface of the metals. Unlike other welding methods, spot welding excels in creating strong, discrete welds without the need for filler materials, making it ideal for thin gauge metals and assemblies where aesthetics and minimal distortion are paramount. The inherent advantages of pneumatic actuation, including rapid response times, precise force control, and minimal maintenance requirements, contribute significantly to its widespread adoption. Modern iterations of these machines integrate advanced programmable logic controllers (PLCs), sophisticated human-machine interfaces (HMIs), and servo-motor driven components, transforming them into intelligent, highly automated solutions. This technological advancement allows for intricate control over welding parameters—such as squeeze time, weld time, hold time, and off time—optimizing the nugget formation and ensuring consistent weld quality across diverse materials, including various grades of steel, stainless steel, and aluminum alloys. The industry is currently witnessing a pronounced trend towards enhanced automation and integration, driven by the persistent pursuit of higher productivity, reduced labor costs, and superior product consistency. Companies are increasingly investing in auto spot welding machine solutions that offer seamless integration with robotic cells and assembly lines, enabling lights-out manufacturing and minimizing human intervention, thereby mitigating risks associated with manual operations and reducing potential for errors. Furthermore, the focus on sustainability and energy efficiency is prompting manufacturers to develop machines that consume less power while delivering superior performance, often through optimized transformer designs and advanced power management systems. This shift is not merely about achieving higher output; it's about fostering a manufacturing environment that is both economically viable and environmentally responsible, aligning with global initiatives for sustainable industrial practices. The evolution from manual to semi-automatic, and now to fully automatic pneumatic spot welders underscores a commitment to innovation that meets the stringent demands of contemporary industrial applications, providing unparalleled precision and reliability in joining metallic components. This foundational understanding sets the stage for a deeper dive into the specific capabilities and strategic advantages offered by cutting-edge pneumatic spot welding technology.

Comprehensive Process Flow: From Raw Material to Precision Weld

The journey of a high-performance pneumatic spot welder, specifically engineered for precision applications like the Fully automatic pneumatic double ear spot welding machine, begins long before it reaches the customer's factory floor. This intricate manufacturing process adheres to stringent quality control and material selection protocols, ensuring each component contributes to the machine's overall durability and operational excellence. The primary structural components, such as the machine frame and critical mechanical linkages, are typically fabricated from high-grade steel, often utilizing precision CNC machining to achieve exceptionally tight tolerances. This choice of material, coupled with advanced manufacturing processes like precision casting for complex parts or robust forging for high-stress components, ensures structural rigidity and long-term stability under continuous industrial operation. Every raw material batch undergoes rigorous incoming inspection, including spectrographic analysis to verify chemical composition and ultrasonic testing to detect internal flaws, aligning with international standards such as ASTM and EN. The electrodes, pivotal to the welding process, are crafted from specialized copper alloys like chromium-zirconium copper (CuCrZr), which offer superior electrical conductivity, high thermal conductivity, and excellent resistance to deformation at elevated temperatures. These electrodes are often precision-machined to specific profiles tailored for various applications, ensuring optimal current density and efficient heat dissipation. During assembly, each sub-component, from the pneumatic cylinders sourced from reputable manufacturers like Festo or SMC, to the custom-wound high-current transformers, is meticulously installed and calibrated. The internal wiring for power and control signals adheres to strict electrical codes (e.g., IEC 60204-1), with industrial-grade shielded cables used to minimize electromagnetic interference (EMI) and ensure signal integrity in harsh industrial environments. Prior to final assembly, critical components like pneumatic valves and pressure regulators undergo individual testing to confirm their operational range and responsiveness. The control system, often built around a robust industrial PLC (e.g., Siemens S7, Allen-Bradley ControlLogix) and integrated with a user-friendly HMI panel, is programmed and extensively tested to manage complex welding sequences, fault detection, and parameter logging. Comprehensive inspection stages are integrated throughout the manufacturing lifecycle, including dimensional inspections after machining, functional testing of sub-assemblies, and electrical safety checks. The final product undergoes a full operational test, simulating real-world working conditions, where weld quality, consistency, and machine performance are validated against predefined parameters. This includes non-destructive testing (NDT) methods like peel tests or chisel tests on sample welds to verify nugget size and integrity, adhering to industry benchmarks for weld quality. Furthermore, the machine's lifespan is engineered for longevity, typically exceeding 10-15 years with proper maintenance, a testament to the quality of materials and manufacturing processes. These machines find indispensable utility across a broad spectrum of applicable industries, notably in the automotive sector for chassis and body panel assembly, the appliance manufacturing industry for components like refrigerator doors and washing machine drums, and the electronics industry for intricate component joining. Beyond these, their application extends to the HVAC sector for ductwork, the aerospace industry for non-critical structural components, and even general sheet metal fabrication. A key advantage of using a pneumatic spot welder in these demanding environments is its inherent capability for energy efficiency; by optimizing the weld cycle and minimizing power consumption during idle times, significant energy savings can be achieved compared to less advanced systems. Moreover, the controlled welding process minimizes the Heat Affected Zone (HAZ), thereby preserving the material's structural integrity and preventing issues like corrosion or deformation, which is particularly critical in applications within industries like petrochemical processing or water treatment, where material stability and corrosion resistance are paramount. The precision of the pneumatic system ensures that consistent force is applied, leading to uniform nugget formation, which is crucial for applications requiring high structural integrity and specific mechanical properties. This detailed manufacturing and testing protocol underscores the commitment to delivering a reliable and high-performing welding solution, meeting and often exceeding international standards such as ISO 9001 for quality management and ANSI/AWS standards for welding processes, ultimately bolstering confidence in the machine's performance and long-term value.

Unpacking Technical Excellence: Parameters, Performance, and Industry Benchmarks

The core strength of any advanced welding solution, especially a high-caliber pneumatic spot welder like the Fully automatic pneumatic double ear spot welding machine, lies in its meticulously engineered technical specifications and the precision with which it can control critical welding parameters. Understanding these parameters is essential for engineers and technical procurement specialists aiming to optimize their manufacturing processes and achieve superior weld quality. Key operational parameters include the welding current, typically measured in kiloamperes (kA), which determines the heat generated; the electrode force, measured in kilonewtons (kN) or pounds-force (lbf), dictating the contact pressure between the workpieces; and the welding time, expressed in cycles or milliseconds, which controls the duration of current flow. For a robust pneumatic spot welder, the welding current can range from 10 kA to over 100 kA for heavy-duty applications, while electrode forces typically vary from 1 kN to 15 kN, depending on material thickness and type. The machine's capability to deliver precise and repeatable control over these parameters directly influences the quality of the weld nugget—its size, strength, and structural integrity. Advanced control systems often feature closed-loop feedback mechanisms that continuously monitor and adjust current and force, compensating for minor variations in material thickness or surface conditions, thereby ensuring consistent weld quality. The transformer design is another critical technical aspect; high-efficiency medium-frequency DC (MFDC) transformers are increasingly common, offering superior power factor, reduced energy consumption, and more stable welding current delivery compared to traditional AC transformers. These MFDC systems can achieve energy savings of up to 30-40% and provide faster response times for current regulation, leading to more robust welds and reduced spatter. Furthermore, the electrode cooling system, often employing a recirculating water chiller, is vital for maintaining electrode tip integrity and extending their lifespan, minimizing the need for frequent tip dressing and replacement, which in turn reduces downtime and operational costs. The integration of advanced diagnostics and monitoring tools allows operators to track key performance indicators (KPIs) such as cycle time, weld count, energy consumption per weld, and fault logs, enabling proactive maintenance and continuous process improvement. Real-time data logging, often compatible with OPC UA or other industrial communication protocols, facilitates seamless integration into broader manufacturing execution systems (MES) or supervisory control and data acquisition (SCADA) platforms, enabling data-driven decision-making and enhancing overall operational transparency.

Typical Parameters for Advanced Pneumatic Spot Welders

| Parameter | Value/Range | Unit | Notes |

|---|---|---|---|

| Welding Current | 20-80 (up to 120 for special models) | kA (Kiloamperes) | Peak current delivery, determines heat generation. |

| Electrode Force | 2-10 (up to 15 for heavy gauge) | kN (Kilonewtons) | Programmable and highly repeatable. |

| Welding Time | 50-500 | ms (Milliseconds) | Adjustable in fine increments (cycles). |

| Throat Depth | 300-800 | mm | Influences accessibility for various part geometries. |

| Power Supply | 380V-480V, 50/60Hz, 3-phase | V/Hz | Standard industrial supply. |

| Cooling System | Water Cooled | Type | Integral or external chiller recommended. |

| Air Pressure Requirement | 0.5-0.8 | MPa | Clean, dry compressed air. |

| Welding Materials | Mild Steel, Stainless Steel, Galvanized Steel, Aluminum | Types | Specific electrode tips for each material. |

Beyond these foundational technical specifications, the adaptability of a pneumatic spot welder to various material thicknesses and types is paramount. High-end machines offer comprehensive material libraries and adaptive welding schedules that can automatically adjust parameters based on sensor inputs, further enhancing versatility and reducing setup times. The integration of advanced features such as automatic electrode tip dressing systems ensures consistent weld quality by maintaining optimal electrode geometry, thus reducing manual intervention and extending electrode life cycle, which translates directly into lower operational costs and improved uptime. Furthermore, the operational noise levels and energy efficiency metrics are increasingly scrutinized by manufacturing companies. Modern pneumatic spot welders are designed with noise reduction in mind, often incorporating acoustic dampening materials and optimized pneumatic circuitry to minimize operational sound, contributing to a more comfortable and compliant working environment. In terms of energy consumption, the shift towards inverter-based power sources with active power factor correction (PFC) dramatically reduces power utility costs and minimizes the carbon footprint, aligning with global sustainability initiatives. These technical refinements underscore a broader industry trend where the focus is not just on raw power or speed, but on intelligent, sustainable, and highly controllable welding processes that deliver consistent, high-quality results while minimizing environmental impact and operational expenditures. The meticulous engineering of these machines ensures that they not only meet but exceed the rigorous demands of contemporary industrial production, setting new benchmarks for efficiency, precision, and reliability in metal joining applications, making them an indispensable asset for any forward-thinking manufacturing facility.

Versatile Applications and Real-World Impact: Driving Productivity Across Industries

The widespread utility of the pneumatic spot welder is vividly demonstrated across a diverse range of industrial applications, each benefiting from its precision, speed, and reliability. From high-volume automotive production lines to intricate electronics assembly, the adaptability of a modern auto spot welding machine like the Fully automatic pneumatic double ear spot welding machine makes it an indispensable tool. In the automotive industry, spot welding is the predominant method for joining sheet metal components of vehicle bodies and chassis. A typical passenger car can have several thousand spot welds, underscoring the critical need for consistency and strength. Our machines are designed to meet the stringent demands of automotive OEMs, providing consistent nugget formation and penetration across various steel grades, including advanced high-strength steels (AHSS), which are crucial for vehicle safety and weight reduction. For example, a leading automotive manufacturer recently deployed our automatic pneumatic double ear spot welding machines for welding critical sub-assemblies of electric vehicle battery packs, achieving a 30% increase in production throughput and a 15% reduction in rework due to the machine's superior repeatability and integrated quality monitoring systems. This success story highlights the transformative impact of precise welding technology on complex manufacturing challenges. Beyond automotive, the appliance manufacturing sector extensively utilizes pneumatic spot welders for assembling components like oven cavities, washing machine tubs, and refrigerator panels. The ability to create clean, strong welds without marring visible surfaces is highly valued in consumer goods where aesthetics are important. In the HVAC industry, these welders are used for ductwork fabrication, joining sheet metal sections efficiently to create airtight and durable ventilation systems. The precise control over electrode force and current ensures minimal distortion, which is crucial for maintaining the structural integrity and airflow efficiency of large duct assemblies. Furthermore, in the electronics industry, smaller, highly agile pneumatic spot welders are employed for connecting delicate components, such as battery tabs to cells, or joining thin gauge materials in sensor housings, where heat management and precise placement are critical to prevent damage to sensitive electronics. A notable case involves a consumer electronics company that integrated our specialized fine-spot welding solution for joining intricate metal components in smartphone chassis, resulting in improved structural integrity and a significant reduction in cosmetic defects, directly enhancing product quality and customer satisfaction. The construction sector also leverages these machines for light structural elements, metal decking, and reinforcing mesh, where rapid and reliable joining is essential for project timelines and safety standards. The inherent advantages of pneumatic systems, such as their simplicity, robustness, and ease of maintenance compared to hydraulic alternatives, make them particularly well-suited for demanding industrial environments where uptime is paramount. Furthermore, the ability to rapidly change welding programs and electrode configurations allows for quick adaptation to different product lines and material specifications, supporting flexible manufacturing strategies. This adaptability, combined with the proven track record of delivering high-quality, repeatable welds, solidifies the position of the pneumatic spot welder as a cornerstone technology driving efficiency, reliability, and innovation across a vast array of industrial applications, contributing directly to product performance and market competitiveness.

Strategic Advantages and Manufacturer Differentiation in the Spot Welding Market

Choosing the right pneumatic spot welder is a strategic decision for any manufacturing entity, directly impacting operational efficiency, product quality, and long-term cost of ownership. The technical advantages of pneumatic systems over other welding technologies are manifold. Firstly, pneumatic systems offer superior speed and responsiveness, enabling rapid electrode movement and quick welding cycles, which translates to higher production rates. This quick response time is crucial for high-volume manufacturing environments where every millisecond counts towards overall throughput. Secondly, the consistency of force application is a significant benefit; pneumatic cylinders provide a very stable and repeatable force profile, which is paramount for achieving uniform weld nuggets and minimizing weld defects like expulsion or insufficient penetration. This consistency ensures predictable weld strength, critical for safety-critical components. Thirdly, pneumatic systems are inherently simpler in design compared to hydraulic alternatives, leading to lower maintenance requirements, fewer potential leak points, and easier troubleshooting, resulting in reduced downtime and lower operational costs over the machine's lifespan. Furthermore, modern pneumatic spot welders are highly energy-efficient, particularly when equipped with advanced inverter power sources. These systems convert AC input to DC current at higher frequencies, significantly reducing transformer size, improving power factor, and minimizing energy waste. This can lead to substantial reductions in electricity bills, aligning with corporate sustainability goals. When evaluating manufacturers, several key differentiation points emerge. Leading manufacturers, like XDR Machinery with its Fully automatic pneumatic double ear spot welding machine, distinguish themselves through a commitment to innovation, comprehensive R&D, and adherence to global quality standards. Our machines are designed with a focus on human-machine interaction, featuring intuitive HMI interfaces that simplify programming and monitoring, reducing the learning curve for operators and enhancing operational flexibility. Beyond the machine itself, the depth of engineering expertise and technical support offered by a manufacturer is critical. This includes pre-sales consultation to identify the optimal welding solution for specific applications, comprehensive training programs for client personnel, and responsive post-sales technical assistance. Certifications such as ISO 9001 for quality management, CE marking for European market compliance, and adherence to American Welding Society (AWS) standards underscore a manufacturer's commitment to quality and safety. Unlike some competitors who offer generic solutions, our approach emphasizes customized solutions, recognizing that each client's production environment and product specifications are unique. This involves tailoring machine dimensions, throat depth, electrode configurations, and even integrating specialized tooling or part handling systems to seamlessly fit into existing production lines. For instance, for a client in the automotive exhaust system manufacturing, we customized a pneumatic spot welder with extended throat depth and specialized C-type guns to reach difficult-to-access welding spots, improving their production efficiency by 25%. Our long-standing service record of over two decades in the industry, coupled with testimonials from global clients, reinforces our authority and trustworthiness. We consistently invest in cutting-edge research to develop solutions that not only meet current industry demands but also anticipate future trends, such as the increasing use of lightweight materials and advanced alloys in manufacturing. This proactive approach ensures our clients remain at the forefront of welding technology, securing a competitive edge in their respective markets. The strategic advantages offered by a technologically advanced pneumatic spot welder, backed by a reputable manufacturer, extend beyond mere machine performance to encompass holistic operational improvements and long-term value creation.

Ensuring Trust and Reliability: Customer Support, Warranty, and Beyond

In the highly competitive B2B landscape, the decision to invest in a major capital expenditure like a Fully automatic pneumatic double ear spot welding machine is heavily influenced not just by technical specifications, but by the assurances of reliability, longevity, and comprehensive post-sales support. A truly authoritative and trustworthy supplier of a pneumatic spot welder differentiates itself through transparent policies and unwavering commitment to customer satisfaction. Our approach to trustworthiness is multifaceted, beginning with a clear and robust warranty policy. We typically offer a 2-year comprehensive warranty on all major components and a lifetime technical support guarantee, underscoring our confidence in the durability and quality of our machines. This warranty covers manufacturing defects and provides peace of mind, minimizing potential financial exposure for our clients. Beyond the initial warranty period, our commitment extends to readily available spare parts and consumables, ensuring minimal downtime in the event of component wear or failure. We maintain a comprehensive inventory of essential parts, ensuring that replacements can be dispatched quickly, often within 24-48 hours for critical components, minimizing operational disruptions. The delivery schedule for our specialized welding machines is meticulously managed and communicated upfront. A typical lead time for a customized pneumatic spot welder ranges from 8 to 12 weeks, depending on the complexity of the configuration and current production load. This includes design, fabrication, assembly, rigorous quality assurance testing, and final packaging. Expedited delivery options can also be discussed for urgent projects. Our logistics team works closely with clients to coordinate shipping and customs procedures, ensuring a smooth and timely delivery process globally. Customer support is the bedrock of our trustworthiness. We provide multi-channel support, including dedicated technical hotlines, email support, and remote diagnostic capabilities. Our team of experienced service engineers is available 24/7 for critical issues, providing immediate troubleshooting and guidance. For complex problems, on-site support can be dispatched globally, ensuring that expert assistance is always within reach. We also offer annual maintenance contracts (AMCs) that include preventive maintenance visits, software updates, and performance optimization, designed to maximize the machine's lifespan and efficiency. For example, a recent client in Southeast Asia reported a 98% uptime rate on their automatic pneumatic double ear spot welding machines over a 3-year period, attributing this success to our prompt technical support and proactive maintenance recommendations. Furthermore, our commitment to customer success includes extensive training programs. We offer both on-site training during machine commissioning and off-site specialized courses at our facilities, covering operational procedures, basic troubleshooting, advanced programming, and safety protocols. These training sessions ensure that client personnel are fully proficient in operating and maintaining the equipment, maximizing their return on investment. Our transparent communication, detailed service reports, and continuous feedback loop from clients are integral to building and maintaining long-term partnerships, reinforcing our reputation as a reliable and trusted supplier in the precision welding industry. This holistic approach to support and service reinforces our commitment to not just selling a machine, but partnering with our clients for their sustained success and operational excellence.

Frequently Asked Questions (FAQs) about Pneumatic Spot Welders

The Future of Welding: Industry Insights and Concluding Perspectives

The trajectory of welding technology, particularly for the pneumatic spot welder, is firmly set towards greater automation, intelligence, and sustainability. Industry 4.0 and the advent of smart factories are driving manufacturers to adopt welding solutions that can seamlessly integrate with broader production ecosystems, enabling real-time data exchange, predictive maintenance, and artificial intelligence-driven process optimization. The ongoing evolution of materials, particularly the proliferation of lightweight and dissimilar materials in sectors like automotive and aerospace, poses new challenges and opportunities for resistance welding. Future developments in pneumatic spot welder technology will likely focus on enhanced adaptive control algorithms that can automatically adjust to variations in material properties, surface coatings, and part fit-up, further minimizing defects and maximizing efficiency. Research is also concentrated on advanced electrode materials and designs that offer extended lifespan and superior current transfer properties, reducing the frequency of maintenance and improving overall uptime. Furthermore, the emphasis on energy efficiency will only intensify, with innovations in power electronics and energy recovery systems playing a crucial role in developing even more environmentally friendly and cost-effective welding solutions. The digital twin concept, where virtual models of welding processes can simulate and optimize performance before physical implementation, is gaining traction, promising significant gains in development speed and process robustness. Another area of active research involves integrating advanced non-destructive testing (NDT) techniques, such as ultrasonic inspection or eddy current testing, directly into the welding cycle, allowing for real-time quality verification of every weld nugget. This level of integrated quality assurance minimizes post-production inspection requirements and ensures unparalleled product reliability. The continuous refinement of control software will also empower operators with more intuitive interfaces and powerful analytical tools, making complex welding tasks more manageable and accessible. The industry is also observing a push towards modular and scalable welding systems, allowing manufacturers to easily expand or reconfigure their production lines to meet changing demands. This flexibility is critical in today's fast-paced manufacturing environment. As a leading provider of the Fully automatic pneumatic double ear spot welding machine, we are actively engaged in these cutting-edge developments, ensuring our clients benefit from the most advanced, reliable, and future-proof welding technologies available. Our commitment to continuous innovation is reflected in our robust R&D pipeline and strategic partnerships with academic institutions and research organizations, ensuring that our products remain at the forefront of the industry. The future of the pneumatic spot welder is bright, promising even greater precision, efficiency, and intelligence to meet the evolving demands of global manufacturing.

References and Further Reading:

-

The Rise of Laser Welding: Precision Meets Power in Modern MetalworkNewsAug.06,2025

-

Streamlining Industrial Packaging: The Power of Barrel Production LinesNewsAug.06,2025

-

Revolutionizing Metal Joining: The Power of Automatic Seam Welding MachinesNewsAug.06,2025

-

Powering Industrial Innovation: The Role of Pipe and Tube Machinery in Modern ManufacturingNewsAug.06,2025

-

Exploring the World of Resistance Welding: Equipment, Manufacturers, and Pricing InsightsNewsAug.06,2025

-

Advancing Container Manufacturing: The Role of the Modern Can Welding MachineNewsAug.06,2025

-

Understanding Automatic Seam Welding Machines: A Game Changer in Welding TechnologyNewsJul.18,2025

-

Pneumatic Handle Welding MachineSep . 13, 2024

Pneumatic Handle Welding MachineSep . 13, 2024 -

Fully Automatic Kaiping Production LineOct . 17, 2024

Fully Automatic Kaiping Production LineOct . 17, 2024 -

Fully Automatic Metal Bucket Lifting HeadphonesSep . 14, 2024

Fully Automatic Metal Bucket Lifting HeadphonesSep . 14, 2024