-

8613931787312

8613931787312 -

Botou Industrial Zone on the east side of National Highway 104, Botou City, Hebei Province

Botou Industrial Zone on the east side of National Highway 104, Botou City, Hebei Province

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- haitian_creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- scottish-gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

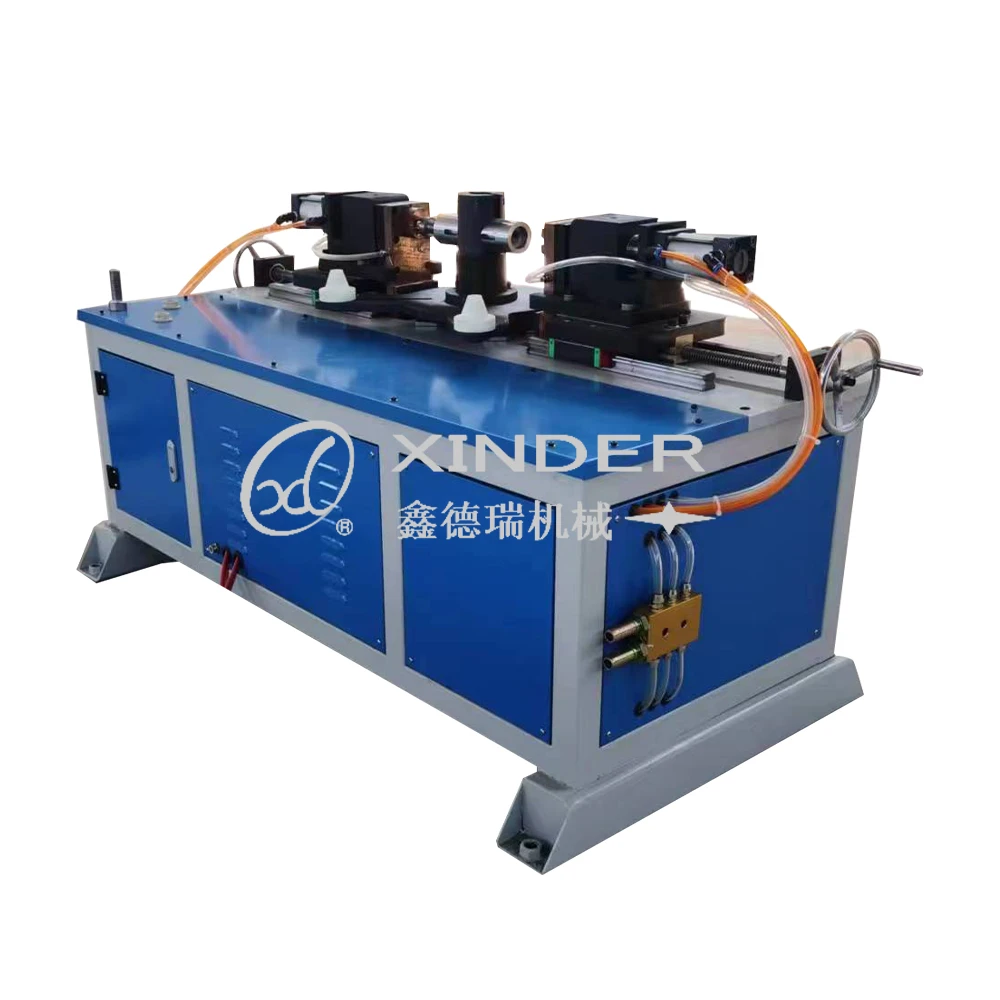

Hydraulic Pipe Cutting Machine - High Precision, Durable & Efficient Pipe Solutions

- Introduction to hydraulic pipe cutting machine

: role in modern manufacturing - Technological breakthroughs in pipe cutting equipment

- Comparing hydraulic, laser, and portable CNC cutting solutions

- Detailed manufacturer and price comparison

- Customizable features and tailored cutting solutions

- Industrial use cases and productivity outcomes

- Future outlook for hydraulic pipe cutting machine and its evolving roles

(hydraulic pipe cutting machine)

Empowering Industry: The Hydraulic Pipe Cutting Machine Revolution

The advent of the hydraulic pipe cutting machine has significantly transformed pipe fabrication and industrial assembly across sectors, including oil and gas, shipbuilding, aerospace, and infrastructure construction. These machines, renowned for their power, accuracy, and adaptability, have become critical to modern manufacturing lines. With the global pipe and tubing market poised to reach a value of $161.1 billion by 2030, efficient and reliable pipe cutting solutions are fundamental for meeting both production volume and quality demands. According to a 2023 survey by Global Industry Analysts Inc., over 62% of large-scale manufacturers attributed a more than 14% increase in output directly to advanced pipe cutting technology integration. In essence, the right machine reduces labor, waste, and downtime—three crucial factors for maintaining competitive advantage.

Breakthroughs in Pipe Cutting: From Hydraulics to Precision Automation

Pipe cutting machine technology has seen a rapid progression from manual sawing to sophisticated, computer-driven systems, dramatically enhancing productivity and safety. Modern models deliver:

- Hydraulic Systems: Offering intense cutting force, typically up to 350 tons, these machines slice through thick-walled pipes with remarkable precision, enabling cut accuracy within ±0.2 mm.

- Laser Pipe Cutting Technology: Utilizing fiber or CO2 lasers operating at 2kW–6kW, this approach provides clean, slag-free cuts at up to 120 m/min, ideal for high-volume production of stainless steel, copper, and aluminum pipes.

- Portable CNC Pipe Cutting: Revolutionizing on-site operations, these machines deliver digital control and error-free replication for custom arch, saddle, hole, or bevel cuts, with productivity increases of up to 35% reported by field operators.

Comparative Analysis: Hydraulic, Laser, and Portable CNC Pipe Cutting Options

The diversity of pipe cutting machinery means careful evaluation is essential to maximize ROI. Here’s a comparative look at leading system types:

| Feature | Hydraulic Pipe Cutting Machine | Laser Pipe Cutting Machine | Portable CNC Pipe Cutting Machine |

|---|---|---|---|

| Cutting Speed | 12–60 m/min | 60–120 m/min | 8–35 m/min |

| Cut Accuracy | ±0.2 mm | ±0.05 mm | ±0.5 mm |

| Pipe Diameter Range | 50–800 mm | 10–650 mm | 20–600 mm |

| Suitable Materials | Steel, Iron, Alloy | Steel, Stainless Steel, Copper, Aluminum | Varied; inc. coated and plastics |

| Initial Investment | $14,000–$55,000 | $43,000–$220,000 | $9,000–$42,000 |

| Maintenance Cost (Yearly) | $900–$1,700 | $1,800–$6,000 | $650–$1,400 |

| Operator Skill Level | Semi-skilled | Advanced; CNC certified | Basic CNC understanding |

| Mobility | Stationary | Stationary | Portable (weight: 45–220kg) |

| Environmental Impact | Low-moderate | Low (dust filtration required) | Very low |

Top Manufacturers and Actual Market Price Exploration

Selecting a trustworthy supplier is critical for enduring performance and after-sales confidence. Industry analysis across leading manufacturers reveals:

| Manufacturer | Country | Hydraulic Pipe Cutting Solutions | Laser Pipe Cutting Machine Price Range | Portable CNC Pipe Cutting Models |

|---|---|---|---|---|

| HGG Profiling Equipment B.V. | Netherlands | SPC 500–1200, ProCutter Series | $98,000–$185,000 | Minibevel, ProCutter CNC |

| Watts Specialties | USA | Model 360/500/80 | N/A | Plasma Pipe CNC, W-2440 |

| Golden Laser | China | N/A | $33,000–$105,000 | P2060A, P3080A |

| Promotech | Poland | PRO36RH Series | N/A | PCM-120, ProCutter Light |

| Jinfeng Machine Tool Co. | China | JFDG-315Y, JFDG-410Y | $21,000–$62,000 | JFCNC-12P, JFCNC-16S |

Customized Pipe Cutting Solutions: Meeting Specific Industrial Needs

The surge in complex piping projects across pharmaceuticals, petrochemicals, and power generation underscores the necessity for customizable cutting solutions. Contemporary pipe cutting machine platforms are now engineered for:

- Variable Pipe Profiles: Accommodate round, square, elliptical, and custom cross-section pipes up to 40mm wall thickness.

- Precision Multiaxis Programming: Simultaneous beveling, grooving, and slotting in a single operation; programmable angles 0°–67°.

- Material Compatibility: Ability to process specialty alloys (Inconel, Hastelloy) with software-guided tool adjustments.

- Workflow Integration: Real-time inventory and quality control reporting, barcode-enabled tracking, and integration with ERP/MES systems for traceability.

- Energy Efficiency: Adaptive power management leading to energy savings of up to 17% per shift compared to conventional systems.

Industrial Case Studies and Productivity Results

Real-world implementations of innovative pipe cutting systems highlight their impact on profitability and operational excellence. For example:

- Global Oil Pipeline Expansion (Asia, 2022–2023): Hydraulic pipe cutting machines contributed to a 27% reduction in project completion time, saving over $9.8 million in labor and welding rework costs.

- Shipyard Modernization (Europe, 2023): Combining laser and portable CNC units, total cut errors dropped from 3.1% to 0.4%, while delivery cycle time shortened by eight weeks.

- Pharmaceutical Cleanroom Construction: Portable machines enabled on-site contamination-free precision cuts, decreasing pipe installation rework by 42% and supporting full FDA compliance.

- Urban Infrastructure (USA, 2023): Multi-vendor, hybrid deployments demonstrated an overall 21% productivity rise, attributed to optimized scheduling and less equipment queuing.

Innovation and the Future of Hydraulic Pipe Cutting Machine Technology

The future of the hydraulic pipe cutting machine is intricately linked to digital transformation and sustainable manufacturing. Forthcoming models will feature cloud-based diagnostics, remote firmware updates, predictive maintenance alerts, and even AI-driven optimization algorithms to fine-tune cut plans in real time. Integration with the Industrial Internet of Things (IIoT) will provide full visibility over every stage of the cutting process. As global manufacturers accelerate the adoption of hybrid lines—including both hydraulic pipe cutting machine platforms and precision robotic interfaces—expect greater precision, efficiency, and flexibility. A continuous commitment to eco-friendly innovation will further reduce energy and material waste. The journey towards zero-defect fabrication, traceable quality, and agile response to new market demands will be led by forward-looking, connected pipe cutting technologies.

(hydraulic pipe cutting machine)

FAQS on hydraulic pipe cutting machine

Q: What is a hydraulic pipe cutting machine?

A: A hydraulic pipe cutting machine uses hydraulic power to cut pipes precisely and efficiently. It's suitable for cutting various pipe materials and sizes. These machines are widely used in construction and manufacturing industries.

Q: How does the price of a laser pipe cutting machine compare to hydraulic pipe cutting machines?

A: Generally, a laser pipe cutting machine price is higher than that of a hydraulic pipe cutting machine due to advanced technology and precision. Laser machines offer cleaner cuts and are ideal for complex shapes. However, hydraulic machines are more budget-friendly for standard cutting tasks.

Q: What are the benefits of a portable CNC pipe cutting machine?

A: A portable CNC pipe cutting machine allows for easy onsite usage and transport. It provides accurate and consistent cuts due to computer numerical control. This increases efficiency and reduces labor costs for cutting pipes in various locations.

Q: Can hydraulic pipe cutting machines be used for stainless steel pipes?

A: Yes, hydraulic pipe cutting machines can be used for stainless steel pipes. They deliver powerful and precise cuts, making them suitable for tough materials. Ensure the machine is fitted with the proper blade for optimal results.

Q: What should I consider when choosing between a hydraulic and a laser pipe cutting machine?

A: Consider your budget, required cutting precision, and types of materials you'll be working with. Laser machines excel in accuracy and complexity but are more expensive. Hydraulic machines are cost-effective and robust for general pipe cutting needs.

-

Understanding Automatic Seam Welding Machines: A Game Changer in Welding TechnologyNewsJul.18,2025

-

Revolutionizing Packaging: The Role of Welding Machines in Steel and Tin Can ManufacturingNewsJul.18,2025

-

Precision in Motion: Exploring Seam Welding Machines for Industrial FabricationNewsJul.18,2025

-

Mastering Precision Bending: A Guide to Tube Benders and Their TypesNewsJul.18,2025

-

Inside the World of Barrel Manufacturing: Machines, Lines, and CostsNewsJul.18,2025

-

Exploring the Technology Behind Elbow Bending Machines in Pipe ManufacturingNewsJul.18,2025

-

Unlocking the Power of Light: Exploring Modern Laser Welding SolutionsNewsJul.15,2025

-

Pneumatic Handle Welding MachineSep . 13, 2024

Pneumatic Handle Welding MachineSep . 13, 2024 -

Fully Automatic Kaiping Production LineOct . 17, 2024

Fully Automatic Kaiping Production LineOct . 17, 2024 -

Fully Automatic Metal Bucket Lifting HeadphonesSep . 14, 2024

Fully Automatic Metal Bucket Lifting HeadphonesSep . 14, 2024