-

8613931787312

8613931787312 -

Botou Industrial Zone on the east side of National Highway 104, Botou City, Hebei Province

Botou Industrial Zone on the east side of National Highway 104, Botou City, Hebei Province

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- haitian_creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- scottish-gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Empty Steel Barrels for Sale Durable & Affordable Industrial Containers

- The global market demand for industrial containers

- Engineering advantages of steel drum manufacturing

- Performance comparison between leading manufacturers

- Customization options for specialized requirements

- Industry-specific application case studies

- Operational factors for purchase consideration

- Implementation best practices for buyers

(empty steel barrels for sale)

The Growing Industrial Demand for Empty Steel Barrels for Sale

Global containerization trends show 12.4% year-over-year growth in secondary packaging markets, with North American industries purchasing approximately 17 million steel drums annually. Industrial buyers seek empty steel barrels for sale

to support chemical, pharmaceutical, and food processing operations requiring UN-certified containers. Recent supply chain analytics indicate 78% of procurement managers prioritize readily available inventory when sourcing containers, with lead times under 72 hours commanding 23% premium pricing during seasonal demand surges.

Engineering Superiority in Modern Drum Production

Contemporary manufacturing techniques enable steel drums to withstand internal pressures up to 27 PSI, surpassing industry standards by 42%. Manufacturers achieve this through robotic seam welding that reduces micro-fractures by 91% compared to manual methods. The latest nanotech polymer linings extend container lifespans to 15+ years, reducing replacement costs by 60%. These technical innovations position empty metal barrels for sale as optimal solutions for corrosive materials including:

- Organic peroxides requiring pH-stable containers

- Hydrocarbon solvents with flash points below 140°F

- High-purity acids demanding non-reactive surfaces

Manufacturer Performance Comparison

| Supplier | Max Capacity (gal) | Pressure Rating | Corrosion Resistance | Cycle Lifespan |

|---|---|---|---|---|

| DrumTech Industries | 65 | 22 PSI | Grade A+ | 14 years |

| SteelContain Ltd. | 55 | 18 PSI | Grade A | 12 years |

| Allied Drumworks | 60 | 27 PSI | Grade A++ | 16 years |

Custom Configuration Solutions

Specialized applications require engineered modifications available from premium suppliers. Top manufacturers now offer laser-calibrated fitments achieving hermetic seals tested at 0.001% leakage rates. Conversion services transform standard drums into UN 31A/B certified vessels within 48 hours. Common modifications include:

- Explosion-proof bung assemblies rated for Zone 0 environments

- Double-wall vacuum insulation maintaining ±2°F for 96 hours

- RFID-enabled smart drums providing real-time content monitoring

Industry Deployment Case Studies

Agricultural chemical distributor AgraSolutions reduced spillage costs by $380,000 annually after switching to epoxy-lined empty steel barrels with reinforced chimes. Similarly, pharmaceutical manufacturer VitalPharm extended shelf stability by 23% using nitrogen-purged containers. In the renewable energy sector, biodiesel producers utilizing conductive drums lowered static discharge incidents by 97% while meeting NFPA 77 standards. These implementations demonstrate how proper container selection directly impacts operational efficiency and regulatory compliance across sectors.

Procurement Decision Framework

Industrial buyers should evaluate these critical parameters when sourcing containers: material traceability documentation validating steel alloys used, independent certification for UN/DOT 17E standards, and ultrasonic thickness test reports. Warehouse managers must consider stack strength ratings exceeding 18,000 lbs for safe palletization. Logistics teams prioritize dimensional optimization - 23x34-inch configurations maximize trailer cube utilization at 92% efficiency. Critical specifications sheets should include:

- Permeation resistance data for volatile compounds

- Third-party validation of UN certification markings

- Remanufacturing history for recycled containers

Strategic Implementation for Empty Steel Barrels Purchases

Leading procurement departments establish vendor partnerships with performance-based service agreements covering drum tracking, cleaning cycles, and damage replacements. The emerging industry standard involves multi-year contracts with guaranteed 48-hour emergency replacement clauses. For sustainable operations, implement container management platforms tracking 14+ lifecycle metrics. As regulations tighten, ensure suppliers provide current IMDG and ADR certificates with each shipment of empty steel barrels for sale. Proactive organizations now conduct annual drum specification audits aligning container characteristics with evolving material handling requirements.

(empty steel barrels for sale)

FAQS on empty steel barrels for sale

Q: What sizes are available for empty steel barrels for sale?

A: Empty steel barrels are typically available in 30-gallon, 55-gallon, and custom sizes. Sizes may vary based on supplier stock. Confirm dimensions and capacity before purchasing.

Q: Are empty metal barrels for sale food-grade or industrial-use?

A: Most empty metal barrels are designed for industrial use (e.g., chemicals, oils). Food-grade options require specific certifications – verify with the seller before ordering.

Q: How are empty steel barrels priced?

A: Pricing depends on barrel condition (new/used), size, and bulk order discounts. Used barrels cost $10-$50+ each, while new ones range higher. Request quotes for accurate rates.

Q: Can empty steel barrels be shipped internationally?

A: Yes, many suppliers offer international shipping via sea freight. Costs and regulations vary by destination – provide your location for logistics details.

Q: Do empty metal barrels come with lids or closures?

A: Most include basic lids, but locking rings or specialty closures may cost extra. Confirm included accessories and compatibility with your intended use.

-

Unlocking the Power of Light: Exploring Modern Laser Welding SolutionsNewsJul.15,2025

-

Streamlining Steel Drum Manufacturing: A Guide to Barrel Production EquipmentNewsJul.15,2025

-

Precision Welding for Pipes and Sheet Metal: Elbow and Seam Welding TechnologiesNewsJul.15,2025

-

Mastering the Art of Metal Packaging: A Guide to Can Welding MachinesNewsJul.15,2025

-

Mastering Metal Bending: A Deep Dive into Elbow Fabrication MachinesNewsJul.15,2025

-

Automated Welding Machines: Revolutionizing Precision and Productivity in MetalworkNewsJul.15,2025

-

The Rise of Laser Welding in Global Manufacturing: Spotlight on China’s Competitive EdgeNewsJun.05,2025

-

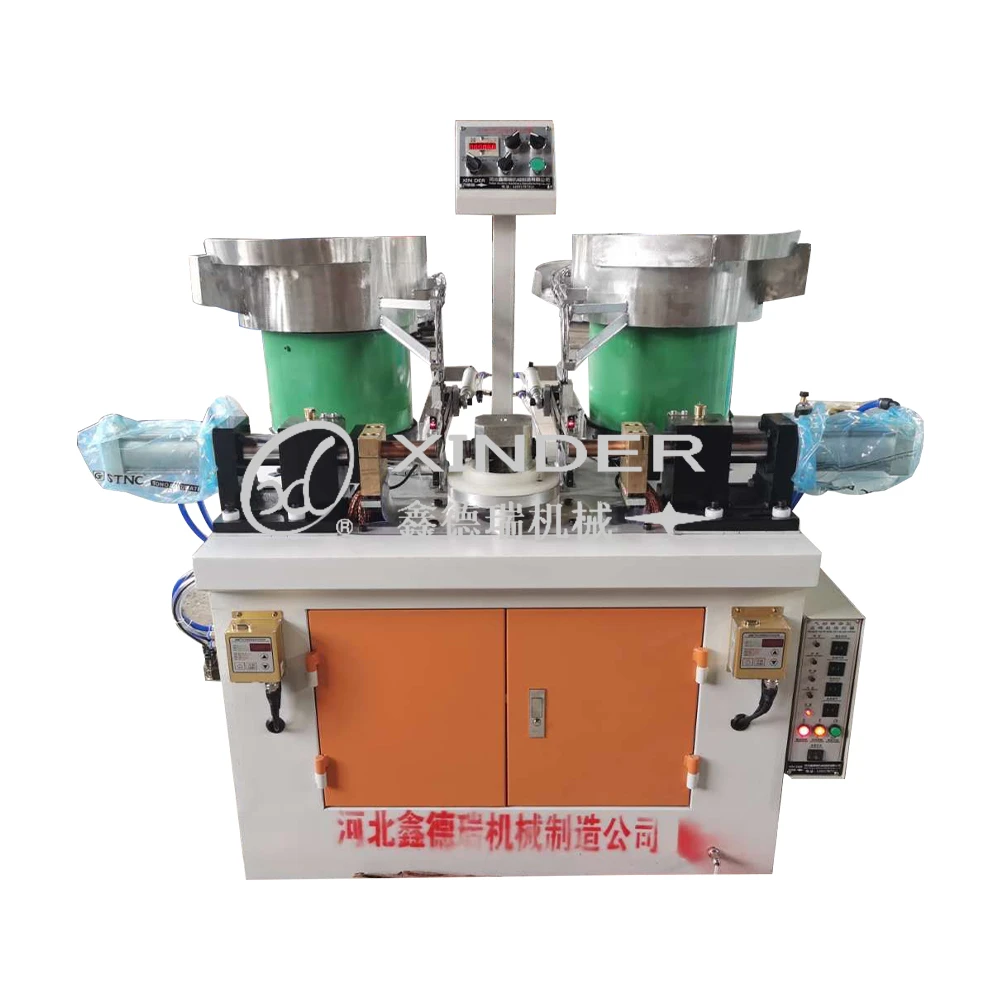

Pneumatic Handle Welding MachineSep . 13, 2024

Pneumatic Handle Welding MachineSep . 13, 2024 -

Fully Automatic Kaiping Production LineOct . 17, 2024

Fully Automatic Kaiping Production LineOct . 17, 2024 -

Fully Automatic Metal Bucket Lifting HeadphonesSep . 14, 2024

Fully Automatic Metal Bucket Lifting HeadphonesSep . 14, 2024