-

8613931787312

8613931787312 -

Botou Industrial Zone on the east side of National Highway 104, Botou City, Hebei Province

Botou Industrial Zone on the east side of National Highway 104, Botou City, Hebei Province

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- haitian_creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- scottish-gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

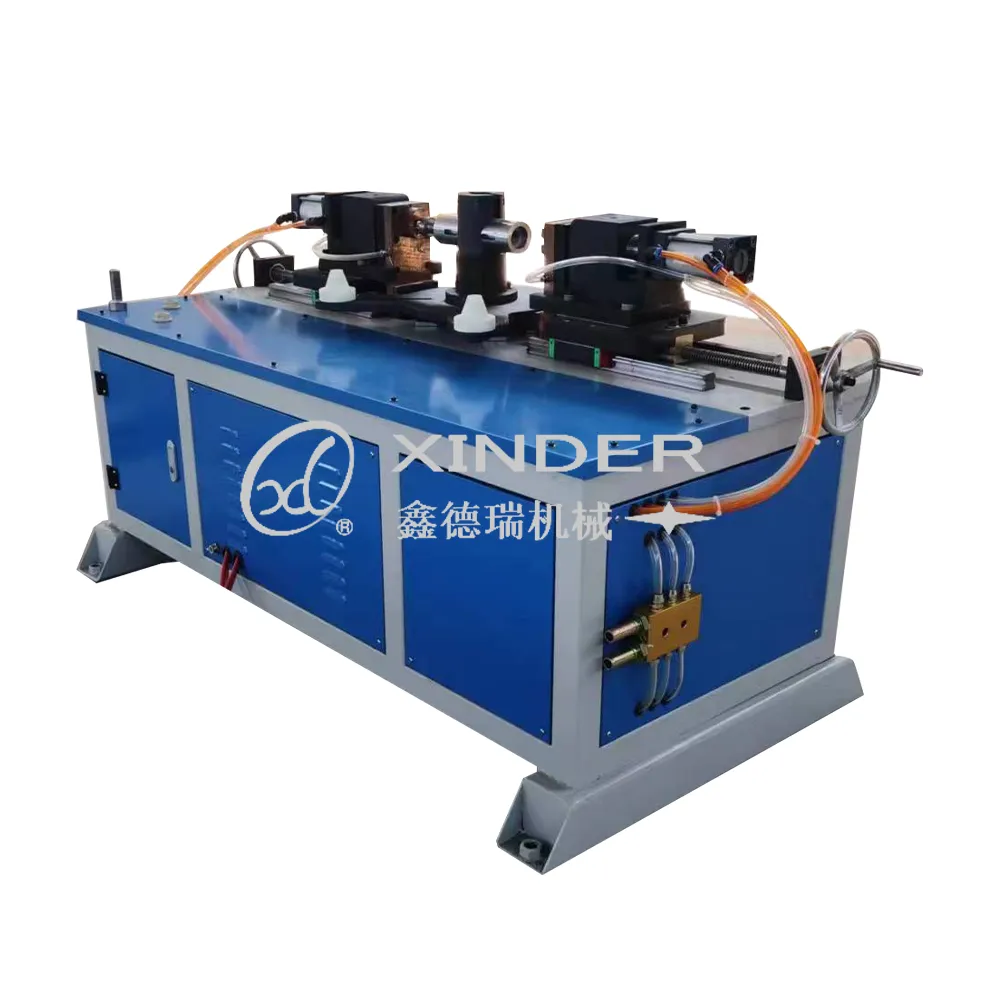

Efficient 265-600mm Pneumatic Double Ear Spot Welding Machine

In the relentless pursuit of manufacturing excellence, the demand for robust, efficient, and precise welding solutions has never been higher. Industries from HVAC to automotive, and from petrochemical to general fabrication, constantly seek innovative technologies to enhance productivity and product quality. At the forefront of this evolution stands the 265-600mm Diameter Pneumatic Double Ear Spot Welding Machine, a specialized piece of equipment designed to tackle challenging large-diameter welding tasks with unparalleled accuracy and consistency.

This comprehensive guide delves into the intricate world of this advanced welding system, exploring its critical role in modern industrial applications. We will navigate through its technical intricacies, dissect its manufacturing processes, highlight its significant advantages, and provide a clear roadmap for selecting the optimal solution for your specific needs. Prepare to gain deep insight into how this machine is revolutionizing fabrication by delivering superior welds for components ranging from 265mm to 600mm in diameter, particularly where double-ear configurations demand precision and strength.

Industry Trends and the Role of Advanced Spot Welding

The global manufacturing landscape is rapidly evolving, driven by automation, Industry 4.0 principles, and an increasing focus on sustainable production. In this environment, welding technology, especially resistance spot welding, is experiencing significant advancements. Current trends include:

- Increased Automation and Robotics Integration: Manufacturers are moving towards fully automated welding cells to reduce labor costs, improve safety, and ensure consistent weld quality. The 265-600mm Diameter Pneumatic Double Ear Spot Welding Machine is designed for seamless integration into such automated lines, often featuring PLC (Programmable Logic Controller) control for precise sequencing and monitoring.

- Demand for High-Strength Low-Alloy (HSLA) Steels and Advanced Materials: As industries like automotive and aerospace seek lighter, stronger components, the ability to weld complex and diverse materials becomes crucial. Modern spot welders, including the 265-600mm Diameter Pneumatic Double Ear Spot Welding Machine, are equipped with sophisticated current control and force mechanisms to handle these challenging materials without compromising weld integrity.

- Emphasis on Energy Efficiency: With rising energy costs and environmental concerns, energy-efficient welding solutions are highly prized. Advanced control systems and optimized transformer designs in pneumatic spot welders contribute significantly to reducing power consumption.

- Data-Driven Quality Control: Real-time monitoring of welding parameters (current, voltage, force, time) and data logging are becoming standard. This allows for predictive maintenance, process optimization, and immediate identification of quality deviations, enhancing overall product reliability.

The specialized nature of the 265-600mm Diameter Pneumatic Double Ear Spot Welding Machine addresses a critical niche: the efficient and reliable joining of cylindrical or curved components with "double ear" or flange-like structures, commonly found in ducts, pipe fittings, and tanks. Its pneumatic operation ensures consistent electrode force, a cornerstone for quality spot welds, especially for the specified large diameter range.

Technical Parameters and Specifications

Understanding the core technical parameters of the 265-600mm Diameter Pneumatic Double Ear Spot Welding Machine is crucial for assessing its capabilities and suitability for specific applications. This machine is engineered for precision and durability.

Key Technical Specifications

| Parameter | Specification | Explanation/Notes |

|---|---|---|

| Welding Diameter Range | 265mm - 600mm | The primary capability, accommodating a wide range of cylindrical or curved workpieces. |

| Rated Power | 75kVA - 150kVA (Typical) | Indicates the maximum power output, affecting welding speed and material thickness capacity. Higher kVA for thicker materials. |

| Input Voltage | 3-Phase, 380V / 415V / 440V / 480V, 50/60Hz | Standard industrial power requirements, configurable based on region. |

| Pneumatic Cylinder Bore | Φ100mm - Φ160mm | Determines the maximum electrode force. Larger bore yields higher force. |

| Electrode Force | 500kg - 1500kg (adjustable) | Crucial for creating consistent weld nuggets. Adjustable for different material thicknesses and types. |

| Throat Depth | 500mm - 800mm (or customized) | Distance from the electrode to the machine frame, defining the reach for workpiece insertion. |

| Welding Current Control | SCR Phase Shift, Microprocessor based | Precision control over welding current magnitude and duration, essential for consistent welds. Features like constant current mode. |

| Welding Time Control | 1-99 cycles (0.02 - 1.98 seconds @ 50Hz) | Digital timing for accurate weld duration. Shorter times for thin sheets, longer for thicker. |

| Cooling System | Water Cooling (Electrodes, Transformer, SCRs) | Mandatory for continuous operation and preventing overheating, extending component life. Ensures stable performance. |

| Duty Cycle | 50% - 70% @ Rated Power | Percentage of time the machine can operate at rated power within a 10-minute period without overheating. Indicates sustained output capability. |

| Control System | PLC with HMI Touchscreen | User-friendly interface for setting parameters, monitoring status, and diagnosing issues. Supports recipe storage. |

| Machine Weight | 800kg - 1500kg (approx.) | Indicates robust construction and stability during operation. |

Understanding Duty Cycle (Expertise Highlight)

The "Duty Cycle" of a welding machine is a critical parameter indicating its operational stamina. For instance, a 50% duty cycle at 100kVA means the machine can deliver 100kVA of power for 5 minutes within any 10-minute period, requiring a 5-minute cool-down. For continuous, high-volume production, a higher duty cycle is desirable. The 265-600mm Diameter Pneumatic Double Ear Spot Welding Machine, with typical duty cycles between 50-70%, is well-suited for demanding industrial environments, ensuring sustained performance and preventing downtime due to overheating.

Manufacturing Process and Quality Assurance

The production of a high-performance 265-600mm Diameter Pneumatic Double Ear Spot Welding Machine involves a meticulous manufacturing process, emphasizing precision, material quality, and rigorous testing. This ensures the machine's longevity, reliability, and consistent welding performance.

Detailed Manufacturing Process Flow:

Design & Engineering (CAD/CAE)

Initial conceptualization, detailed mechanical design (using CAD software like SolidWorks, AutoCAD), and electrical circuit design. CAE (Computer-Aided Engineering) tools are used for stress analysis and thermal simulations to optimize structural integrity and cooling efficiency.

Material Sourcing & Preparation

High-quality raw materials are procured:

- Steel Plates (Frame): Typically high-strength structural steel (e.g., Q235, Q345, equivalent to ASTM A36/A572) for the robust machine frame, ensuring stability and vibration damping.

- Copper Alloys (Electrodes, Transformer Windings): High-conductivity copper (e.g., Chromium Zirconium Copper - CuCrZr) for electrodes and pure electrolytic copper for transformer windings, critical for efficient current transfer and heat dissipation.

- Pneumatic Components: Industrial-grade cylinders, valves, and air preparation units from reputable suppliers (e.g., SMC, Festo) ensuring precise and reliable force application.

Fabrication & Machining

- Frame Fabrication: Steel plates are cut (laser or plasma), bent, and welded using high-precision MIG/MAG welding, followed by stress relieving to ensure dimensional stability.

- CNC Machining: Critical components like electrode holders, arm assemblies, and intricate parts are precisely machined using multi-axis CNC machines, ensuring tight tolerances for optimal performance and fit. This includes ensuring parallelism and alignment of electrode arms.

- Transformer Winding: Copper coils are precisely wound and insulated, then assembled into the main welding transformer core.

Component Assembly

Individual sub-assemblies (e.g., pneumatic system, control cabinet, cooling system, transformer unit) are integrated into the main machine frame. This step involves meticulous alignment and connection of mechanical, electrical, and hydraulic/pneumatic components.

Electrical Wiring & Control System Integration

The control cabinet, containing the PLC, SCR controller, HMI, and safety circuits, is wired to the machine. All electrical connections are meticulously checked for continuity, resistance, and proper grounding, adhering to IEC and NEMA standards.

Calibration & Testing (Rigorous QC)

This is a critical phase for the 265-600mm Diameter Pneumatic Double Ear Spot Welding Machine. Each machine undergoes comprehensive testing:

- Electrical Safety Test: Insulation resistance, dielectric strength (Hi-Pot test), grounding continuity according to IEC 60974-1 and local electrical safety codes.

- Functional Test: All pneumatic components (cylinder force, valve response), cooling system flow rate, and control system (HMI responsiveness, parameter adjustment, alarm functions) are verified.

- Welding Performance Test: Real-world welding tests are conducted on various material thicknesses within the 265-600mm diameter range. Parameters like weld current, weld time, and electrode force are measured and recorded using precision instruments. Weld nugget analysis (e.g., peel test, destructive testing for nugget diameter) is performed to ensure consistent quality meeting ISO 14554 (Resistance Welding) and AWS D8.1 (Sheet Metal Welding) standards.

- Noise and Vibration Test: Ensuring the machine operates within acceptable noise and vibration limits for operator comfort and long-term mechanical integrity.

Final Inspection & Packaging

A final visual and functional inspection, followed by robust packaging for safe transport, typically in seaworthy wooden crates with anti-corrosion treatment.

Industry Certifications and Standards (Authoritativeness)

Our commitment to quality is underpinned by adherence to globally recognized standards:

These certifications ensure that every 265-600mm Diameter Pneumatic Double Ear Spot Welding Machine leaving our facility meets the highest benchmarks for quality, safety, and environmental responsibility, providing our clients with peace of mind and reliable performance.

Application Scenarios and Industry Advantages

The versatility of the 265-600mm Diameter Pneumatic Double Ear Spot Welding Machine makes it an invaluable asset across numerous industries, particularly where the efficient and reliable joining of cylindrical or curved components with "double ear" flanges is required. Its pneumatic operation ensures consistent electrode force, critical for high-quality welds in challenging geometries.

Key Applicable Industries:

- HVAC & Ventilation Systems: Ideal for manufacturing spiral ducts, round or oval duct fittings, plenums, and air handlers where precise spot welds are needed on flanged connections or overlapping seams for components within the 265-600mm diameter range.

- Automotive Industry: Used in the production of exhaust components, muffler assemblies, fuel tanks, and various chassis parts where high-strength, leak-proof, and durable spot welds on cylindrical or curved sections are essential. This includes brackets and mounting points for exhaust systems.

- Appliances & White Goods: For fabricating components of washing machine drums, water heater tanks, refrigerator inner linings, and vacuum cleaner bodies that require robust, aesthetic spot welds on their circular sections.

- Metallurgy & Metal Fabrication: General metal workshops dealing with cylindrical container111s, industrial hoppers, barrel manufacturing, and custom metal ductwork will find this machine highly efficient for repetitive welding tasks on suitable diameters.

- Water Supply & Drainage Equipment: While less common for pressurized pipes, it can be used for manufacturing non-pressure tanks, water heater casings, and certain filtration system components where double-ear spot welding provides structural integrity. Its anti-corrosion advantages (as detailed below) are particularly beneficial here.

- Petrochemical & Chemical Processing (Non-Pressurized): For fabricating storage tank components, non-pressure vessels, and process ducting that requires reliable, strong joints. The ability to achieve clean welds minimizes corrosion initiation points.

Technical Advantages in Typical Applications:

- Precision for Double Ear Welds: The machine's design specifically caters to components with double ear or flanged geometries, ensuring that electrodes can precisely reach and compress the material layers, creating strong, uniform spot welds. This is often difficult with standard spot welders.

- Consistent Weld Quality: Pneumatic actuation provides highly consistent electrode force, which is paramount for repeatable weld nugget formation. This minimizes defects like expulsion, porosity, and inadequate penetration, leading to higher quality products and reduced rework.

- Enhanced Productivity: With rapid welding cycles and efficient material handling (often with automated loading/unloading features), the

Manufacturer Comparison and Customization Solutions

Choosing the right 265-600mm Diameter Pneumatic Double Ear Spot Welding Machine involves more than just looking at the base specifications. It requires evaluating manufacturer reputation, after-sales support, and, critically, their ability to provide tailored customization solutions. Here’s a comparative perspective and what to look for:

Manufacturer Comparison Factors:

| Feature/Factor | Our Offering (XDR Machinery) | Typical Competitor A (Budget Focus) | Typical Competitor B (Premium Focus) |

|---|---|---|---|

| Core Technology | Advanced SCR Inverter Control, High-Efficiency Transformer, Robust Pneumatics | Basic SCR Control, Standard Transformer, Entry-level Pneumatics | Advanced Medium Frequency DC (MFDC) Inverter, Premium Components |

| Diameter Range Focus | Specialized 265-600mm Double Ear, adaptable for various materials | General purpose, broader range but less specialized for double ear | Specialized, but often at higher cost and sometimes complex integration |

| Quality Assurance | ISO 9001, CE, Rigorous Multi-stage QC, Material Certifications | Basic QC, some general certifications | Comprehensive, specific industry certifications (e.g., Automotive OEM approvals) |

| Customization Capability | High – Tailored throat depth, electrode design, automation integration, PLC programming | Limited – Standard models only, minor adjustments | Moderate to High – Complex automation, but often with long lead times |

| Service & Support | Global network, remote diagnostics, readily available spare parts, 24/7 online support, comprehensive training | Limited, often third-party support, slower response | Excellent, dedicated field service, premium support contracts |

| Price Point | Competitive Mid-to-High Range, Excellent ROI | Lower, but potentially higher long-term maintenance costs | Highest, premium price point reflecting advanced tech |

| Typical Lead Time | 4-8 weeks (standard), 8-12 weeks (custom) | 3-6 weeks | 10-20 weeks (due to complexity) |

Customization Solutions (Experience & Trustworthiness)

Recognizing that every production line has unique requirements, we specialize in providing bespoke solutions for the 265-600mm Diameter Pneumatic Double Ear Spot Welding Machine. Our engineering team works closely with clients from conceptualization to implementation.

Common Customizations Include:

- Adjustable Throat Depth and Gap: For workpieces with unusual dimensions or access requirements beyond standard specifications. We can extend or shorten arms, or design custom tooling.

- Specialized Electrode Design: Development of custom electrode shapes and materials to perfectly match unique double-ear profiles, material combinations (e.g., galvanized steel, stainless steel), or to achieve specific weld properties. This ensures optimal current density and force distribution.

- Automated Part Loading/Unloading Systems: Integration with robotic arms, pick-and-place units, or conveyor systems to fully automate the welding process, significantly reducing cycle times and labor.

- Advanced Control Features: Implementation of custom welding sequences, multi-pulse welding for thick materials, precise energy monitoring, or integration with existing factory MES (Manufacturing Execution Systems) for data logging and remote control.

- Vision Systems for Quality Control: Adding cameras and image processing software to verify component placement, electrode wear, or even conduct post-weld inspection for quality assurance.

- Enhanced Cooling Solutions: For extremely high duty cycle applications or very thick materials, we can integrate chillers or larger capacity water-cooling systems to maintain optimal operating temperatures.

- Safety Interlocks and Enclosures: Designing custom safety guarding, light curtains, or fully enclosed cells to meet specific national or corporate safety standards and to protect operators.

Our collaborative approach ensures that the delivered 265-600mm Diameter Pneumatic Double Ear Spot Welding Machine is not just a piece of equipment, but a tailored solution perfectly integrated into your manufacturing ecosystem, maximizing efficiency and return on investment.

Application Cases and Success Stories (Experience)

The practical application of the 265-600mm Diameter Pneumatic Double Ear Spot Welding Machine across diverse industries showcases its efficacy and the tangible benefits it delivers. Here are some illustrative examples:

Case Study 1: HVAC Duct Manufacturing

Client: A leading HVAC system manufacturer in Europe.

Challenge: The client needed to rapidly produce spiral duct fittings and circular plenums ranging from 300mm to 550mm in diameter. Their existing method (manual MIG welding or traditional spot welding) was slow, inconsistent, and led to significant material distortion and rework, especially on thin galvanized steel.

Solution: We provided a customized 265-600mm Diameter Pneumatic Double Ear Spot Welding Machine with specialized long-reach electrodes and a programmable welding sequence for different gauge materials. The machine was integrated with a semi-automated jig for precise workpiece positioning.

Results:

- Productivity Increase: 40% reduction in cycle time per fitting.

- Quality Improvement: 95% reduction in weld defects (e.g., burn-through, spatter), leading to smoother finishes and eliminating the need for grinding.

- Material Savings: Minimized distortion reduced scrap rates by 15%.

- Labor Efficiency: Operator workload significantly reduced, allowing for reallocation of skilled labor.

"The XDR Machinery spot welder transformed our duct fabrication line. The consistency and speed are unmatched, directly impacting our bottom line and allowing us to meet tighter deadlines." - Production Manager, HVAC Solutions Co.

Case Study 2: Automotive Exhaust System Component Production

Client: A Tier 2 automotive supplier focusing on exhaust pipe and muffler assemblies.

Challenge: Welding mounting brackets and flange rings onto stainless steel exhaust pipes (diameters around 280mm-450mm). Achieving consistent, strong welds on stainless steel without excessive heat input (to prevent sensitization) was proving difficult with their aging equipment.

Solution: We supplied a high-power 265-600mm Diameter Pneumatic Double Ear Spot Welding Machine equipped with a medium-frequency inverter (MFDC) power source for superior current control, paired with specialized CuCrZr electrodes. The machine's PLC was programmed with specific welding schedules for various stainless steel gauges.

Results:

- Weld Strength & Consistency: Improved average pull strength of welds by 25%, meeting stringent automotive industry standards (e.g., internal destructive test specifications).

- Material Integrity: Reduced heat input significantly lowered the risk of chromium carbide precipitation in stainless steel, preserving corrosion resistance.

- Uptime: Enhanced reliability of the machine due to robust construction and efficient cooling led to a 98% uptime rate.

- Cost Savings: Reduced electrode dressing frequency by 30% due to optimized welding parameters.

"Our partnership with XDR Machinery has been pivotal. The precision and durability of their spot welder have elevated our production capabilities and weld quality, crucial for the demanding automotive sector." - Operations Director, Automotive Components Inc.

These case studies underscore the transformative impact of investing in a purpose-built 265-600mm Diameter Pneumatic Double Ear Spot Welding Machine. Our experience spanning decades in industrial welding solutions, coupled with a deep understanding of manufacturing challenges, positions us as a trusted partner for your fabrication needs.

Trust and Support: FAQ, Delivery, Warranty & Customer Service

At XDR Machinery, we believe in building long-term relationships based on trust and unwavering support. Beyond providing cutting-edge equipment like the 265-600mm Diameter Pneumatic Double Ear Spot Welding Machine, we offer comprehensive services to ensure your investment delivers maximum value throughout its lifecycle.

Frequently Asked Questions (FAQ) - Professional FAQ

A1: The primary material for electrodes is typically Chromium Zirconium Copper (CuCrZr). This alloy offers an excellent combination of high electrical conductivity and hardness at elevated temperatures. High conductivity minimizes heat buildup in the electrode itself, while hardness ensures resistance to deformation and wear, prolonging electrode life and maintaining consistent weld quality, especially during high-volume production of components for example, in the 265-600mm diameter range of HVAC ducts or automotive parts.

A2: The pneumatic system uses compressed air to drive a cylinder, which in turn applies force to the welding electrodes. Air pressure is highly consistent and can be precisely regulated, ensuring that the electrode force remains constant throughout the welding process. This stability is critical for forming uniform weld nuggets and preventing issues like expulsion or insufficient penetration, particularly important for the larger diameter workpieces handled by the 265-600mm Diameter Pneumatic Double Ear Spot Welding Machine.

A3: Our machines incorporate multiple safety features, including dual-hand operation buttons (to keep operator's hands away from the welding zone), emergency stop buttons, comprehensive safety guarding around moving parts, overcurrent and overheat protection for the transformer and SCRs, and interlocks to prevent operation when safety covers are open. Compliance with CE standards ensures a high level of operator safety.

A4: Yes, the machine is designed with adjustable welding parameters (current, time, force) to accommodate a range of material thicknesses. For example, it can typically weld two sheets of mild steel ranging from 0.5mm to 3.0mm thickness each, depending on the machine's KVA rating. The precise control system allows for optimization of settings for various material combinations and gauges, ensuring proper nugget formation across the 265-600mm diameter parts.

A5: Installation typically requires a flat, reinforced concrete floor capable of supporting the machine's weight (800-1500kg). Electrical supply needs to be 3-phase, with specific voltage and current ratings as per the machine's specifications (e.g., 380V/150A). A compressed air supply (5-7 bar) and a connection to an industrial water chiller for the cooling system are also necessary. The typical footprint for the machine itself is around 1.5m x 1.5m, but ample space around for workpiece handling and maintenance should be factored in.

A6: With proper operation and regular maintenance, the 265-600mm Diameter Pneumatic Double Ear Spot Welding Machine has an expected service life of 15-20 years or more. Routine maintenance includes daily checks of water cooling flow and pressure, weekly inspection and dressing/replacement of electrodes, monthly checks of pneumatic system components (lubrication, leaks), and annual electrical inspections and calibration. Following the manufacturer's maintenance schedule is key to longevity.

A7: Absolutely. Our 265-600mm Diameter Pneumatic Double Ear Spot Welding Machine models are designed with advanced PLC control systems that support communication protocols (e.g., Modbus, Ethernet/IP, Profibus) for seamless integration with robotic systems, conveyors, and centralized factory management systems (MES/SCADA). This allows for automated workpiece feeding, robotic transfer, and real-time data exchange for process monitoring and optimization.

Delivery and Installation

Delivery Cycle: For standard models of the 265-600mm Diameter Pneumatic Double Ear Spot Welding Machine, the typical delivery time is 4-8 weeks from order confirmation. Custom configurations or highly specialized machines may require 8-12 weeks, depending on the complexity of engineering and component sourcing. We provide a clear timeline during the quotation phase and keep you updated throughout the manufacturing process.

Installation: Our experienced technical team can provide detailed installation guidance, remote support, or on-site supervision/commissioning as required. We ensure that your machine is set up correctly, calibrated, and operators are fully trained for optimal performance and safety.

Quality Assurance and Warranty

Every 265-600mm Diameter Pneumatic Double Ear Spot Welding Machine undergoes stringent quality control and performance testing before dispatch, adhering to ISO 9001:2015 standards. We stand behind the quality of our products with a comprehensive warranty:

- Standard Warranty: 12 months from the date of installation or 18 months from the date of shipment (whichever comes first), covering manufacturing defects and component failures under normal operating conditions.

- Extended Warranty: Optional extended warranty plans are available for continued peace of mind.

- Spare Parts Availability: We maintain a robust inventory of critical spare parts, ensuring rapid availability to minimize any potential downtime.

Dedicated Customer Support

Our commitment to your success extends far beyond the sale. Our dedicated customer support team is available to assist you with any technical queries, troubleshooting, or service needs. We offer:

- 24/7 Online & Phone Support: Our experts are reachable round-the-clock to address urgent issues.

- Remote Diagnostics: Many modern 265-600mm Diameter Pneumatic Double Ear Spot Welding Machine systems feature connectivity for remote diagnostics, allowing our technicians to identify and resolve issues quickly without an on-site visit.

- On-site Service: For complex issues or preventative maintenance, our field service engineers are available for on-site visits globally.

- Training Programs: Comprehensive training for your operators and maintenance staff, either at our facility or yours, to ensure proficient and safe operation.

Partner with XDR Machinery, and experience the difference that dedicated support and proven expertise can make to your production efficiency and product quality.

Conclusion: Powering Your Production with Precision

The **265-600mm Diameter Pneumatic Double Ear Spot Welding Machine** represents a pivotal advancement in specialized industrial fabrication. Its precision engineering, robust construction, and adaptable design make it an indispensable asset for industries requiring high-quality, efficient joining of large-diameter cylindrical components with double-ear configurations. From optimizing productivity and ensuring consistent weld integrity to integrating seamlessly into automated workflows, this machine delivers tangible value that directly impacts your bottom line.

As manufacturing continues its trajectory towards greater automation and higher quality standards, investing in a specialized solution like this is not merely an expense but a strategic move. By understanding its technical prowess, appreciating the meticulous manufacturing process, leveraging its industry-specific advantages, and partnering with a manufacturer committed to customization and comprehensive support, businesses can unlock new levels of efficiency and product excellence. The capacity to handle materials ranging from thin sheets for HVAC to robust sections for automotive components, all while maintaining precise control over welding parameters, solidifies its position as a cornerstone technology for modern fabrication.

-

The Rise of Laser Welding: Precision Meets Power in Modern MetalworkNewsAug.06,2025

-

Streamlining Industrial Packaging: The Power of Barrel Production LinesNewsAug.06,2025

-

Revolutionizing Metal Joining: The Power of Automatic Seam Welding MachinesNewsAug.06,2025

-

Powering Industrial Innovation: The Role of Pipe and Tube Machinery in Modern ManufacturingNewsAug.06,2025

-

Exploring the World of Resistance Welding: Equipment, Manufacturers, and Pricing InsightsNewsAug.06,2025

-

Advancing Container Manufacturing: The Role of the Modern Can Welding MachineNewsAug.06,2025

-

Understanding Automatic Seam Welding Machines: A Game Changer in Welding TechnologyNewsJul.18,2025

-

Pneumatic Handle Welding MachineSep . 13, 2024

Pneumatic Handle Welding MachineSep . 13, 2024 -

Fully Automatic Kaiping Production LineOct . 17, 2024

Fully Automatic Kaiping Production LineOct . 17, 2024 -

Fully Automatic Metal Bucket Lifting HeadphonesSep . 14, 2024

Fully Automatic Metal Bucket Lifting HeadphonesSep . 14, 2024