-

8613931787312

8613931787312 -

Botou Industrial Zone on the east side of National Highway 104, Botou City, Hebei Province

Botou Industrial Zone on the east side of National Highway 104, Botou City, Hebei Province

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- haitian_creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- scottish-gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

जन . 16, 2025 01:15

Back to list

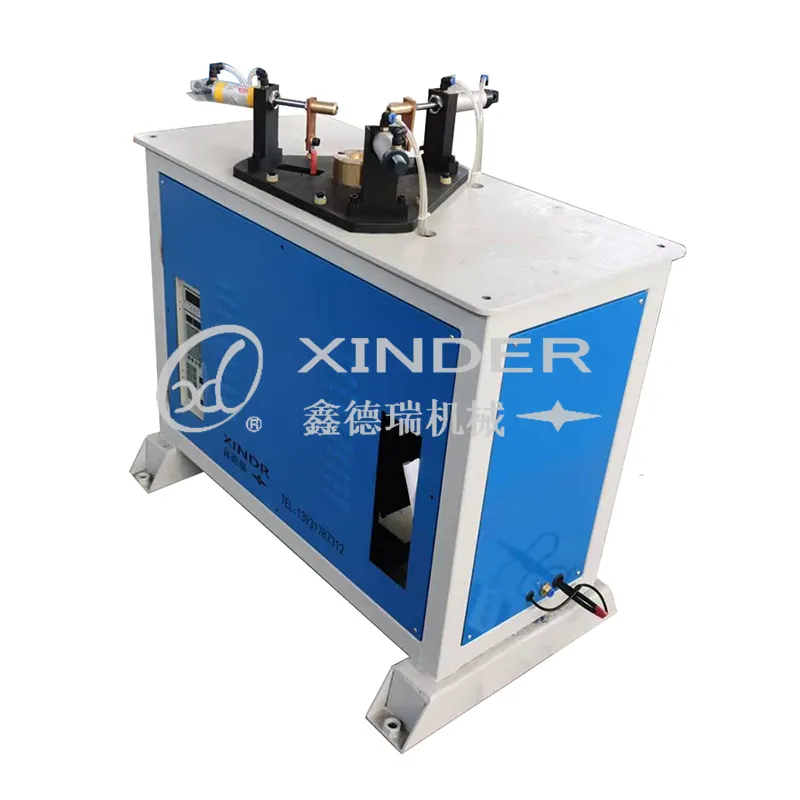

laser welder with wire feed

The laser welder with wire feed is revolutionizing metalwork in industries ranging from automotive to aerospace. As professionals in these fields continue to seek efficiency, precision, and reliability, the integration of wire feed technology with laser welding emerges as a game-changer.

In terms of authoritativeness, the application of this technology is being championed by leading manufacturers across the globe. Continuous research and development efforts from industry leaders ensure these machines incorporate the latest advances. From augmented reality interfaces that guide novice operators to sophisticated algorithms that adjust laser parameters in real time, these developments solidify the standing of laser welders with wire feed as a cornerstone technology in modern manufacturing. Trustworthiness in the performance of laser welders with wire feed is well-documented. They provide high repeatability and a consistent performance record, which is especially important for industries like aerospace that cannot afford any variability. Comprehensive testing and real-world applications prove their reliability across different scenarios. This technology not only optimizes production but also reduces the likelihood of errors, thus instilling confidence among operators and stakeholders alike. In conclusion, the laser welder with wire feed is not just an innovation—it's a necessity for forward-thinking industries where quality cannot be compromised. Its combination of precision, versatility, and innovation makes it a superior choice. Those investing in such technology are not merely upgrading their equipment; they are securing a future where craftsmanship meets the pinnacle of modern engineering.

In terms of authoritativeness, the application of this technology is being championed by leading manufacturers across the globe. Continuous research and development efforts from industry leaders ensure these machines incorporate the latest advances. From augmented reality interfaces that guide novice operators to sophisticated algorithms that adjust laser parameters in real time, these developments solidify the standing of laser welders with wire feed as a cornerstone technology in modern manufacturing. Trustworthiness in the performance of laser welders with wire feed is well-documented. They provide high repeatability and a consistent performance record, which is especially important for industries like aerospace that cannot afford any variability. Comprehensive testing and real-world applications prove their reliability across different scenarios. This technology not only optimizes production but also reduces the likelihood of errors, thus instilling confidence among operators and stakeholders alike. In conclusion, the laser welder with wire feed is not just an innovation—it's a necessity for forward-thinking industries where quality cannot be compromised. Its combination of precision, versatility, and innovation makes it a superior choice. Those investing in such technology are not merely upgrading their equipment; they are securing a future where craftsmanship meets the pinnacle of modern engineering.

Prev:

Next:

Latest News

-

Understanding Seam Welding Technology: Applications and Equipment OverviewNewsAug.15,2025

-

The Rise of Automation in Welding: Enhancing Precision and ProductivityNewsAug.15,2025

-

The Applications and Importance of Laser Welding in Modern ManufacturingNewsAug.15,2025

-

Revolutionizing Industrial Welding with Automatic Seam Welding TechnologyNewsAug.15,2025

-

Precision and Efficiency in Metal Packaging: The Role of Can Welding MachinesNewsAug.15,2025

-

Advancing Metal Joining Technologies with Laser Welding and Soldering SolutionsNewsAug.15,2025

-

The Rise of Laser Welding: Precision Meets Power in Modern MetalworkNewsAug.06,2025

related products

-

Pneumatic Handle Welding MachineSep . 13, 2024

Pneumatic Handle Welding MachineSep . 13, 2024 -

Fully Automatic Kaiping Production LineOct . 17, 2024

Fully Automatic Kaiping Production LineOct . 17, 2024 -

Fully Automatic Metal Bucket Lifting HeadphonesSep . 14, 2024

Fully Automatic Metal Bucket Lifting HeadphonesSep . 14, 2024