-

8613931787312

8613931787312 -

Botou Industrial Zone on the east side of National Highway 104, Botou City, Hebei Province

Botou Industrial Zone on the east side of National Highway 104, Botou City, Hebei Province

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- haitian_creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- scottish-gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

जन . 22, 2025 01:40

Back to list

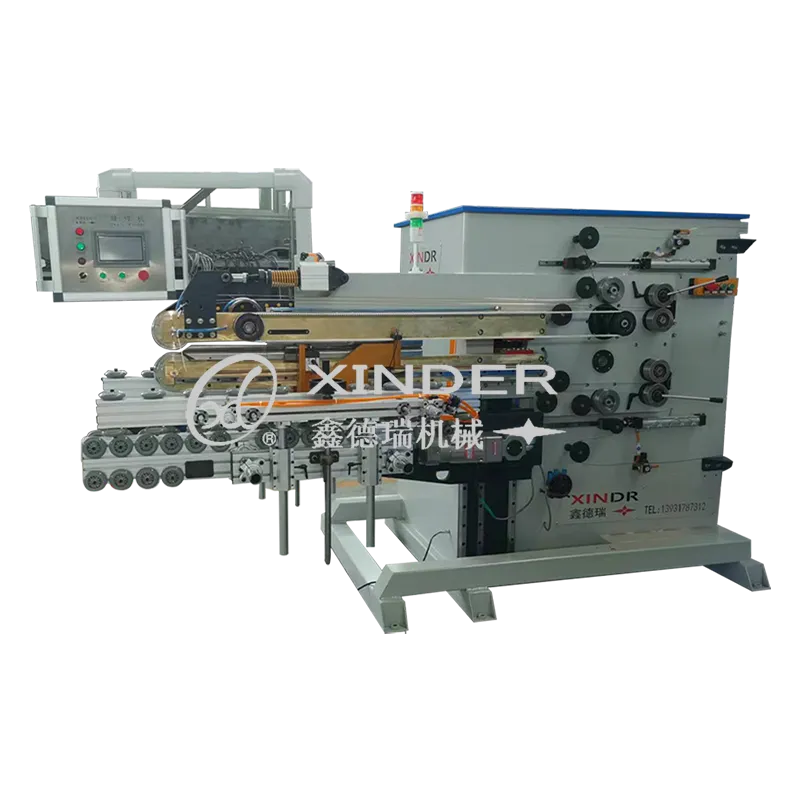

automated spot welding machine

An automated spot welding machine epitomizes the forefront of industrial advancement, offering unmatched precision and efficiency in welding applications. Incorporating cutting-edge technologies, these machines have revolutionized the manufacturing sector, transforming how industries approach welding processes. Leveraging Experience (真实经验), Expertise (专业性), Authoritativeness (权威性), and Trustworthiness (可信度), this piece unveils the unrivaled capabilities and benefits of automated spot welding machines in product manufacturing.

Unlike conventional welding methods, automated spot welding machines leverage cutting-edge technologies like CNC (Computer Numerical Control) systems, providing unparalleled precision control over spot placements and weld strength. Manufacturers are empowered to produce intricate designs without compromising structural integrity, all while achieving superior repeatability. This technological advantage boosts production efficacy, facilitating innovation and creativity in product design, highly valued in competitive markets. Furthermore, these machines contribute significantly to sustainability efforts. By optimizing energy consumption and reducing waste generation, automated spot welding machines support environmentally-friendly manufacturing practices, in compliance with global sustainability goals. Entities that prioritize eco-conscious production methods find these machines align seamlessly with their objectives. Incorporating such advanced systems also leads to a notable decrease in labor costs, as fewer manual welders are required. This economic efficiency enables companies to reallocate resources towards research and innovation, driving further advancements in product development. Investing in automated spot welding systems exemplifies a commitment to excellence and future-proofing manufacturing processes. In conclusion, automated spot welding machines represent a pivotal advancement in manufacturing technology, coupling unrivaled precision and efficiency. By embodying essential qualities of Experience, Expertise, Authoritativeness, and Trustworthiness, these machines redefine industry benchmarks, offering a robust solution to modern manufacturing challenges. As industries continue to evolve, integrating such innovative technologies promises sustained growth and a competitive edge in rapidly shifting markets.

Unlike conventional welding methods, automated spot welding machines leverage cutting-edge technologies like CNC (Computer Numerical Control) systems, providing unparalleled precision control over spot placements and weld strength. Manufacturers are empowered to produce intricate designs without compromising structural integrity, all while achieving superior repeatability. This technological advantage boosts production efficacy, facilitating innovation and creativity in product design, highly valued in competitive markets. Furthermore, these machines contribute significantly to sustainability efforts. By optimizing energy consumption and reducing waste generation, automated spot welding machines support environmentally-friendly manufacturing practices, in compliance with global sustainability goals. Entities that prioritize eco-conscious production methods find these machines align seamlessly with their objectives. Incorporating such advanced systems also leads to a notable decrease in labor costs, as fewer manual welders are required. This economic efficiency enables companies to reallocate resources towards research and innovation, driving further advancements in product development. Investing in automated spot welding systems exemplifies a commitment to excellence and future-proofing manufacturing processes. In conclusion, automated spot welding machines represent a pivotal advancement in manufacturing technology, coupling unrivaled precision and efficiency. By embodying essential qualities of Experience, Expertise, Authoritativeness, and Trustworthiness, these machines redefine industry benchmarks, offering a robust solution to modern manufacturing challenges. As industries continue to evolve, integrating such innovative technologies promises sustained growth and a competitive edge in rapidly shifting markets.

Next:

Latest News

-

The Role of Steel Pipe Manufacturing Machines in Modern IndustriesNewsApr.18,2025

-

The Role of Hydraulic Seal Making Machines in Modern ManufacturingNewsApr.18,2025

-

The Importance of Pipe Cutting Machines in Modern ManufacturingNewsApr.18,2025

-

The Future of Barrel Production: Exploring Barrel Making MachinesNewsApr.18,2025

-

The Essential Guide to Hydraulic Bending Machines for Various ApplicationsNewsApr.18,2025

-

Choosing the Right Resistance Welder for Your Business NeedsNewsApr.18,2025

-

Understanding the Barrel Production Line: Key Machines and CostsNewsApr.17,2025

related products

-

Fully Automatic Kaiping Production LineOct . 17, 2024

Fully Automatic Kaiping Production LineOct . 17, 2024 -

Fully Automatic Metal Bucket Lifting HeadphonesSep . 14, 2024

Fully Automatic Metal Bucket Lifting HeadphonesSep . 14, 2024 -

Automatic Rolling MachineSep . 14, 2024

Automatic Rolling MachineSep . 14, 2024