-

8613931787312

8613931787312 -

Botou Industrial Zone on the east side of National Highway 104, Botou City, Hebei Province

Botou Industrial Zone on the east side of National Highway 104, Botou City, Hebei Province

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- haitian_creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- scottish-gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

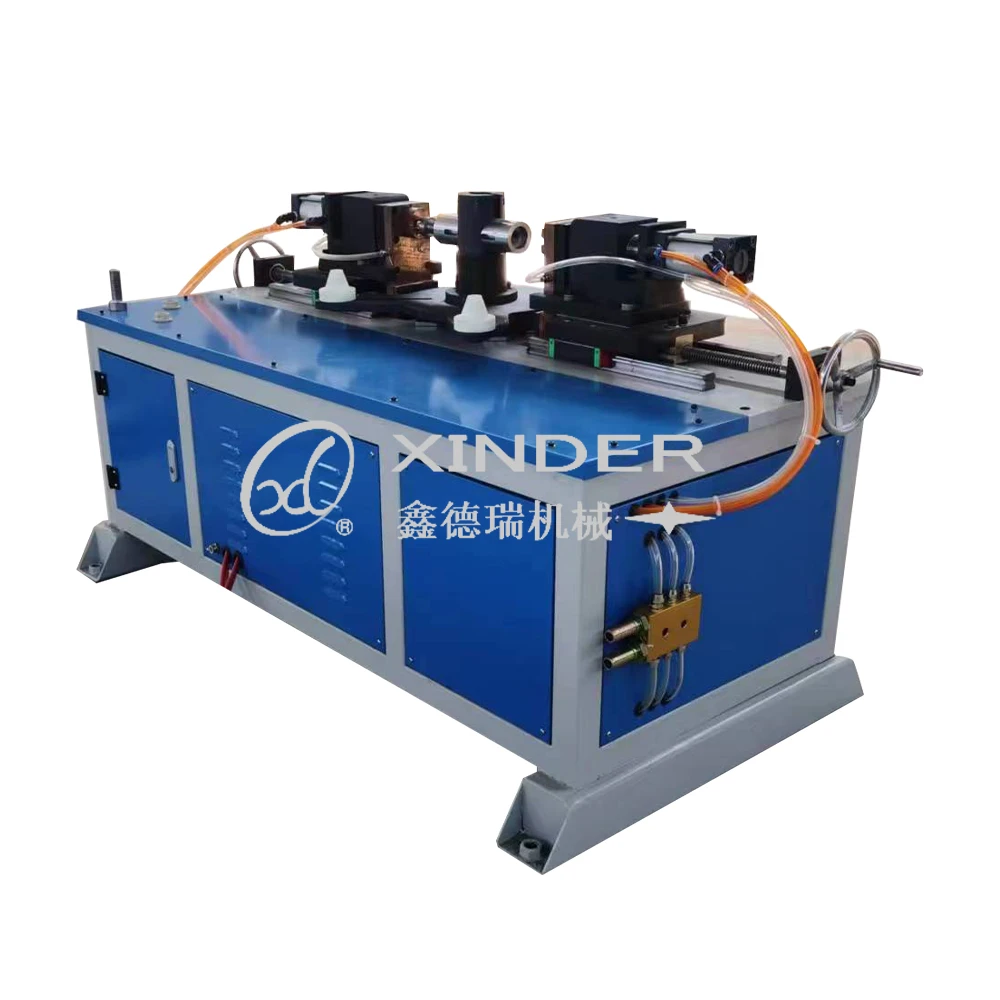

Affordable Automatic PVC Pipe Cutting Machine Cost and Features

The Price of Automatic PVC Pipe Cutting Machines An Overview

In today's fast-paced manufacturing environment, efficiency is key to staying competitive. Automatic PVC pipe cutting machines represent a significant investment for companies looking to enhance their production capabilities, streamline operations, and improve overall accuracy in pipe fabrication processes. Understanding the factors that influence the price of these machines is essential for businesses considering a purchase.

What is an Automatic PVC Pipe Cutting Machine?

An automatic PVC pipe cutting machine is a specialized piece of equipment designed to cut polyvinyl chloride (PVC) pipes with precision and speed. These machines automate the cutting process, reducing the labor required and minimizing the potential for human error. Most models are equipped with advanced features such as programmable settings, adjustable cutting speeds, and various blade options, making them adaptable for different types of PVC pipes and diameters.

Factors Influencing the Price

Several factors can influence the price of automatic PVC pipe cutting machines

1. Machine Specifications The size, cutting capacity, and technology used in the machine significantly impact its price. Higher capacity machines that can handle larger diameters and longer pipes typically cost more. Additionally, machines with advanced features like computer numerical control (CNC) or laser cutting technology may also command a higher price tag due to their enhanced precision and automation capabilities.

2. Brand and Manufacturer Renowned brands known for their quality and durability often charge a premium for their equipment. While these machines may be more expensive upfront, they often provide greater reliability and can be more cost-effective in the long run due to lower maintenance costs and longer lifespans.

3. Customization and Features Various optional features can increase the price of a machine. For instance, additional tooling, software for enhanced operation management, improved safety features, and integration capabilities with other manufacturing equipment can all affect cost. Businesses that require specific customizations will likely find that these options raise the overall price of the cutting machine.

automatic pvc pipe cutting machine price

4. Market Trends and Demand The broader market conditions, including supply chain issues or fluctuations in the PVC industry, can also impact pricing. A surge in demand for construction and plumbing projects can increase the demand for cutting machines, potentially leading to higher prices across the board.

5. Location and Shipping Depending on where a business operates, shipping costs and local market conditions can affect the final price of the machinery. Import taxes, tariffs, and regional sales taxes may also add to the overall expense.

Typical Price Range

As of recent data, the price range for automatic PVC pipe cutting machines can vary widely. Basic models designed for small to medium operations may start at around $5,000. In contrast, more advanced machines featuring higher capacities, automation, and precision could cost upwards of $20,000 or more. For large enterprises requiring high-volume production, custom solutions can exceed this range significantly.

Return on Investment

When considering the purchase of an automatic PVC pipe cutting machine, it’s crucial to evaluate the potential return on investment (ROI). For many manufacturers, the advantages of faster production speeds, reduced labor costs, and improved accuracy can quickly justify the expense. Additionally, the efficiency gains can lead to enhanced output and the ability to take on more projects.

Conclusion

Investing in an automatic PVC pipe cutting machine can be a game-changer for companies in the plumbing, construction, or manufacturing industries. By understanding the factors that influence pricing and weighing the potential benefits against the costs, businesses can make informed decisions that will enhance their operational efficiency and competitiveness in the market. As technology continues to advance, these machines will likely become even more integral to successful production processes.

-

The Rise of Laser Welding in Global Manufacturing: Spotlight on China’s Competitive EdgeNewsJun.05,2025

-

The Power of Precision: Exploring the Role of Automatic Seam Welding Machines in Modern ManufacturingNewsJun.05,2025

-

The Essential Guide to Can Welding Machines: Revolutionizing the Packaging IndustryNewsJun.05,2025

-

Resistance Welding Equipment: A Smart Investment for Industrial ManufacturingNewsJun.05,2025

-

Precision Welding for Modern Manufacturing: The Rise of Automatic Seam Welding MachinesNewsJun.05,2025

-

Laser Welding for Stainless Steel: The Precision Edge in Modern Metal FabricationNewsJun.05,2025

-

The Modern Evolution of Barrel Production: Technology, Machines, and Market PricingNewsMay.22,2025

-

Fully Automatic Kaiping Production LineOct . 17, 2024

Fully Automatic Kaiping Production LineOct . 17, 2024 -

Fully Automatic Metal Bucket Lifting HeadphonesSep . 14, 2024

Fully Automatic Metal Bucket Lifting HeadphonesSep . 14, 2024 -

Automatic Rolling MachineSep . 14, 2024

Automatic Rolling MachineSep . 14, 2024