-

8613931787312

8613931787312 -

Botou Industrial Zone on the east side of National Highway 104, Botou City, Hebei Province

Botou Industrial Zone on the east side of National Highway 104, Botou City, Hebei Province

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- haitian_creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- scottish-gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

1-р сар . 13, 2025 11:33

Back to list

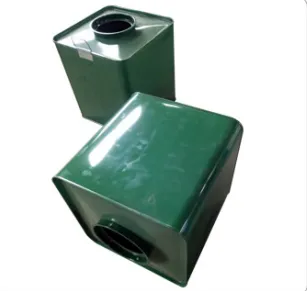

pneumatic welding machine

Pneumatic welding machines have revolutionized the industrial landscape by providing a more efficient and versatile approach to welding. These machines harness the power of compressed air to apply force, ensuring precision and accuracy in various welding processes. The result is a seamless and high-quality weld that meets the demands of modern manufacturing standards.

Authoritativeness in the pneumatic welding machine industry is largely dictated by the reputation of the manufacturers and the innovations they bring to the market. Leading companies invest heavily in research and development to enhance the capabilities of these machines, integrating features such as advanced control interfaces, automation, and real-time monitoring systems. These innovations not only boost performance but also enhance the machine's reliability and lifespan. When selecting a pneumatic welding machine, it is essential to consider manufacturers with a proven track record of quality and innovation. Trustworthiness is a key factor in the adoption of pneumatic welding machines. Users need to be assured that the equipment will perform consistently and meet safety standards. Reliable customer support, comprehensive warranties, and positive user testimonials contribute significantly to building trust between manufacturers and end-users. Furthermore, compliance with international safety and quality standards, such as ISO certification, is essential for ensuring that the machines are safe to operate and produce high-quality welds. In conclusion, pneumatic welding machines offer a compelling combination of precision, versatility, and efficiency for modern manufacturing. Their ability to accommodate a wide variety of materials and applications, coupled with the expertise and innovation from leading manufacturers, makes them an indispensable tool in the industrial sector. As technology advances, these machines will continue to evolve, providing even greater benefits in terms of performance, safety, and cost-effectiveness.

Authoritativeness in the pneumatic welding machine industry is largely dictated by the reputation of the manufacturers and the innovations they bring to the market. Leading companies invest heavily in research and development to enhance the capabilities of these machines, integrating features such as advanced control interfaces, automation, and real-time monitoring systems. These innovations not only boost performance but also enhance the machine's reliability and lifespan. When selecting a pneumatic welding machine, it is essential to consider manufacturers with a proven track record of quality and innovation. Trustworthiness is a key factor in the adoption of pneumatic welding machines. Users need to be assured that the equipment will perform consistently and meet safety standards. Reliable customer support, comprehensive warranties, and positive user testimonials contribute significantly to building trust between manufacturers and end-users. Furthermore, compliance with international safety and quality standards, such as ISO certification, is essential for ensuring that the machines are safe to operate and produce high-quality welds. In conclusion, pneumatic welding machines offer a compelling combination of precision, versatility, and efficiency for modern manufacturing. Their ability to accommodate a wide variety of materials and applications, coupled with the expertise and innovation from leading manufacturers, makes them an indispensable tool in the industrial sector. As technology advances, these machines will continue to evolve, providing even greater benefits in terms of performance, safety, and cost-effectiveness.

Latest News

-

The Rise of Laser Welding: Precision Meets Power in Modern MetalworkNewsAug.06,2025

-

Streamlining Industrial Packaging: The Power of Barrel Production LinesNewsAug.06,2025

-

Revolutionizing Metal Joining: The Power of Automatic Seam Welding MachinesNewsAug.06,2025

-

Powering Industrial Innovation: The Role of Pipe and Tube Machinery in Modern ManufacturingNewsAug.06,2025

-

Exploring the World of Resistance Welding: Equipment, Manufacturers, and Pricing InsightsNewsAug.06,2025

-

Advancing Container Manufacturing: The Role of the Modern Can Welding MachineNewsAug.06,2025

-

Understanding Automatic Seam Welding Machines: A Game Changer in Welding TechnologyNewsJul.18,2025

related products

-

Pneumatic Handle Welding MachineSep . 13, 2024

Pneumatic Handle Welding MachineSep . 13, 2024 -

Fully Automatic Kaiping Production LineOct . 17, 2024

Fully Automatic Kaiping Production LineOct . 17, 2024 -

Fully Automatic Metal Bucket Lifting HeadphonesSep . 14, 2024

Fully Automatic Metal Bucket Lifting HeadphonesSep . 14, 2024