-

8613931787312

8613931787312 -

Botou Industrial Zone on the east side of National Highway 104, Botou City, Hebei Province

Botou Industrial Zone on the east side of National Highway 104, Botou City, Hebei Province

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- haitian_creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- scottish-gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

2 сар . 01, 2025 04:59

Back to list

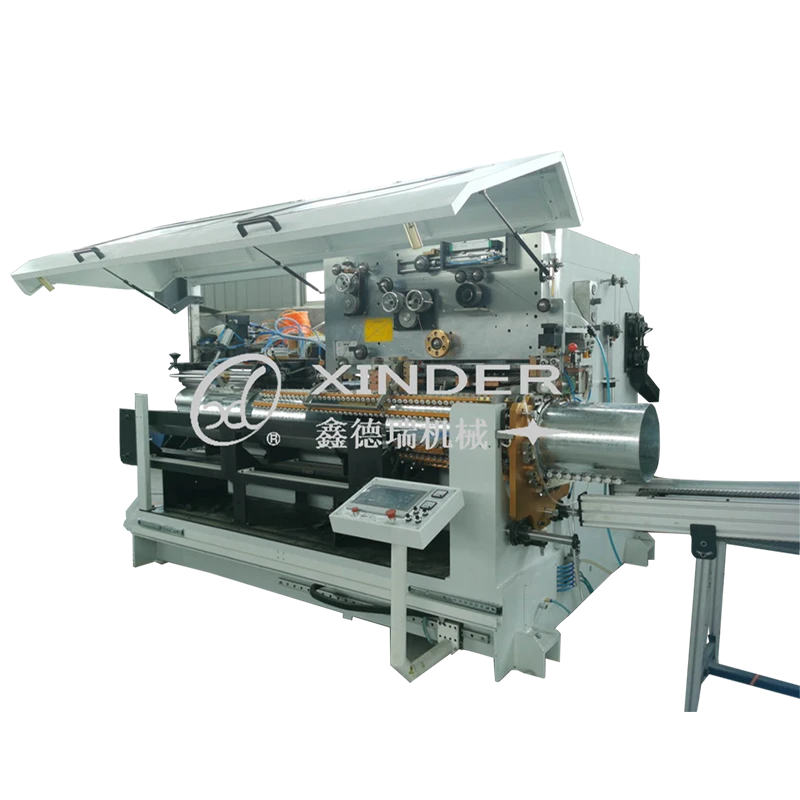

Corrugated Metal Elbow Production Line

In the intricate world of industrial manufacturing, the evolution of the barrel making machine stands as a testament to both innovation and precision. With a history as rich as the resources it helps manage, the modern barrel making machine is an epitome of technological advancement, solving age-old challenges in storage and transportation with unparalleled efficiency.

Authoritativeness in the field is demonstrated by manufacturers and industry leaders who continuously innovate and set benchmarks for quality and performance. Prestigious brands in the sector leverage decades of research and feedback to enhance machine functionalities, incorporating eco-friendly technologies and energy-saving mechanisms. Their commitment to quality is reflected in rigorous testing and certification processes, ensuring that their machines comply with international safety and efficiency standards. Trustworthiness is crucial, particularly in industries where safety and durability of the barrels are paramount. Reliable manufacturers offer comprehensive warranties and support services, fostering long-term trust and partnerships with clients. Furthermore, user testimonials and case studies provide potent evidence of machine reliability and longevity. Prospective buyers are advised to seek out these endorsements, ensuring they invest in machines that deliver proven results. In conclusion, the modern barrel making machine is a remarkable convergence of tradition and technology, serving as a backbone to key global industries. While the initial investment might seem substantial, the long-term benefits of high productivity, reduced labor, and precise output present undeniable advantages. Companies striving for excellence in production should consider incorporating these machines into their operations, aligning with their goals of achieving superior quality and operational efficiency. Such strategic moves not only bolster an enterprise’s market position but also pave the way for sustainable growth in an ever-evolving industrial landscape.

Authoritativeness in the field is demonstrated by manufacturers and industry leaders who continuously innovate and set benchmarks for quality and performance. Prestigious brands in the sector leverage decades of research and feedback to enhance machine functionalities, incorporating eco-friendly technologies and energy-saving mechanisms. Their commitment to quality is reflected in rigorous testing and certification processes, ensuring that their machines comply with international safety and efficiency standards. Trustworthiness is crucial, particularly in industries where safety and durability of the barrels are paramount. Reliable manufacturers offer comprehensive warranties and support services, fostering long-term trust and partnerships with clients. Furthermore, user testimonials and case studies provide potent evidence of machine reliability and longevity. Prospective buyers are advised to seek out these endorsements, ensuring they invest in machines that deliver proven results. In conclusion, the modern barrel making machine is a remarkable convergence of tradition and technology, serving as a backbone to key global industries. While the initial investment might seem substantial, the long-term benefits of high productivity, reduced labor, and precise output present undeniable advantages. Companies striving for excellence in production should consider incorporating these machines into their operations, aligning with their goals of achieving superior quality and operational efficiency. Such strategic moves not only bolster an enterprise’s market position but also pave the way for sustainable growth in an ever-evolving industrial landscape.

Latest News

-

Unlocking the Power of Light: Exploring Modern Laser Welding SolutionsNewsJul.15,2025

-

Streamlining Steel Drum Manufacturing: A Guide to Barrel Production EquipmentNewsJul.15,2025

-

Precision Welding for Pipes and Sheet Metal: Elbow and Seam Welding TechnologiesNewsJul.15,2025

-

Mastering the Art of Metal Packaging: A Guide to Can Welding MachinesNewsJul.15,2025

-

Mastering Metal Bending: A Deep Dive into Elbow Fabrication MachinesNewsJul.15,2025

-

Automated Welding Machines: Revolutionizing Precision and Productivity in MetalworkNewsJul.15,2025

-

The Rise of Laser Welding in Global Manufacturing: Spotlight on China’s Competitive EdgeNewsJun.05,2025

related products

-

Pneumatic Handle Welding MachineSep . 13, 2024

Pneumatic Handle Welding MachineSep . 13, 2024 -

Fully Automatic Kaiping Production LineOct . 17, 2024

Fully Automatic Kaiping Production LineOct . 17, 2024 -

Fully Automatic Metal Bucket Lifting HeadphonesSep . 14, 2024

Fully Automatic Metal Bucket Lifting HeadphonesSep . 14, 2024