-

8613931787312

8613931787312 -

Botou Industrial Zone on the east side of National Highway 104, Botou City, Hebei Province

Botou Industrial Zone on the east side of National Highway 104, Botou City, Hebei Province

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- haitian_creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- scottish-gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

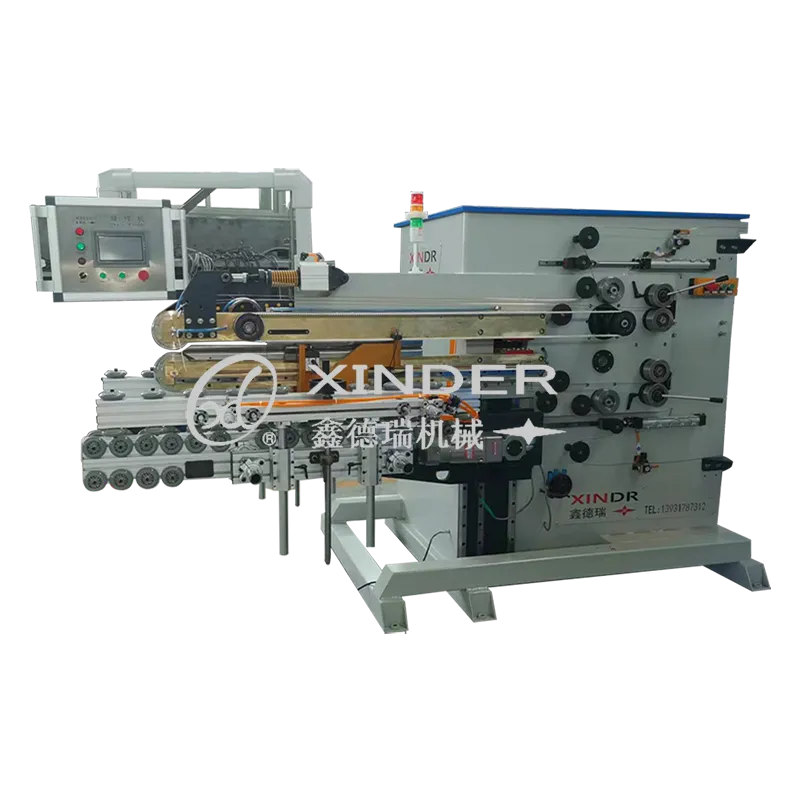

4 roll bending machine

Understanding the 4% Roll Bending Machine A Key Tool for Metal Fabrication

In the world of metal fabrication, precision and efficiency are paramount. One of the standout devices that facilitate these objectives is the roll bending machine, particularly those designed with a 4% bending capability. This article delves into the mechanics, applications, and advantages of the 4% roll bending machine, illustrating its significance in various industries.

What is a Roll Bending Machine?

A roll bending machine is a specialized piece of equipment designed to bend metal sheets and plates into curved shapes. The machine typically consists of three rollers, positioned in a triangular arrangement, that can be adjusted to achieve different radii of curvature. The rollers are powered, allowing for continuous bending of metal as it passes through the machine. The designation of 4% signifies the machine's capacity to bend materials to a certain degree, which can be crucial for specific applications.

Functionality of the 4% Roll Bending Machine

The most notable feature of a 4% roll bending machine is its ability to bend materials within a specified range of thickness and radius. The machine can produce bends up to 4% of the material's thickness, which translates into greater versatility in shaping various types of metals. This functionality is essential for industries that require precise and uniform bends, such as the automotive, aerospace, and construction sectors.

With advancements in technology, modern roll bending machines are increasingly equipped with digital controls that allow operators to set parameters with high precision. This not only enhances the accuracy of the bends but also reduces waste, as the machine can be calibrated to meet specific requirements.

Applications in Various Industries

4 roll bending machine

The 4% roll bending machine is widely utilized across multiple sectors. In the automotive industry, for instance, it is commonly used to bend metal for frames, chassis, and body parts. The ability to create complex curves and turns is vital for designing components that must fit together seamlessly. Similarly, in aerospace, the machine is instrumental in fabricating parts that require a high degree of curvature while maintaining structural integrity.

In the construction industry, roll bending machines are employed to create curved beams, frames, and architectural elements. The aesthetic appeal and functional requirements of modern architecture demand precision bending capabilities, making the 4% roll bending machine an invaluable asset. Furthermore, the shipbuilding industry benefits from these machines as they create the hulls and other components that require specific bends to ensure buoyancy and durability.

Advantages of Using a 4% Roll Bending Machine

One of the key advantages of using a 4% roll bending machine is the efficiency and speed with which it operates. Unlike other bending processes, which may require multiple setups and manual adjustments, the roll bending machine simplifies the workflow, allowing for quick transitions between different bends and thicknesses. This operational speed can significantly reduce production times and overall costs.

Moreover, the precision provided by these machines greatly minimizes material waste. By accurately calculating the necessary bends, fabricators can employ strategies that optimize the use of metal sheets, saving both time and resources.

The flexibility of the 4% roll bending machine also deserves mention. Operators can easily adapt the machine for different materials, including stainless steel, aluminum, and mild steel. This adaptability ensures that businesses can cater to diverse client needs without the necessity of investing in multiple machines.

Conclusion

In conclusion, the 4% roll bending machine stands as a crucial tool in the realm of metal fabrication. Its precise bending capabilities, coupled with speed and adaptability, make it indispensable across various industries ranging from automotive to construction. As technology continues to advance, these machines will likely become even more refined, further enhancing their role in shaping the future of metalwork. Embracing such innovative equipment can lead to improved production efficiency and quality, ensuring that businesses remain competitive in an ever-evolving marketplace.

-

The Rise of Laser Welding in Global Manufacturing: Spotlight on China’s Competitive EdgeNewsJun.05,2025

-

The Power of Precision: Exploring the Role of Automatic Seam Welding Machines in Modern ManufacturingNewsJun.05,2025

-

The Essential Guide to Can Welding Machines: Revolutionizing the Packaging IndustryNewsJun.05,2025

-

Resistance Welding Equipment: A Smart Investment for Industrial ManufacturingNewsJun.05,2025

-

Precision Welding for Modern Manufacturing: The Rise of Automatic Seam Welding MachinesNewsJun.05,2025

-

Laser Welding for Stainless Steel: The Precision Edge in Modern Metal FabricationNewsJun.05,2025

-

The Modern Evolution of Barrel Production: Technology, Machines, and Market PricingNewsMay.22,2025

-

Pneumatic Handle Welding MachineSep . 13, 2024

Pneumatic Handle Welding MachineSep . 13, 2024 -

Fully Automatic Kaiping Production LineOct . 17, 2024

Fully Automatic Kaiping Production LineOct . 17, 2024 -

Fully Automatic Metal Bucket Lifting HeadphonesSep . 14, 2024

Fully Automatic Metal Bucket Lifting HeadphonesSep . 14, 2024