-

8613931787312

8613931787312 -

Botou Industrial Zone on the east side of National Highway 104, Botou City, Hebei Province

Botou Industrial Zone on the east side of National Highway 104, Botou City, Hebei Province

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- haitian_creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- scottish-gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Vas . 16, 2025 01:50

Back to list

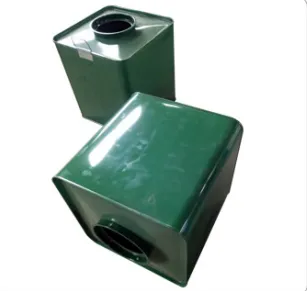

Fully Automatic Welded Pipe Machine

Investing in an electrofusion pipe welder can revolutionize your approach to pipeline installation and repair. An electrofusion pipe welder is a sophisticated tool designed to join plastic pipes and fittings using a controlled electrical process. This advanced technique has gained popularity due to its efficacy in creating strong, durable joints that withstand the test of time and environmental stresses.

Moreover, the controlled nature of the electrofusion process eliminates many variables that can undermine welding reliability. Each weld is recorded in a data log, allowing for transparency and traceability which is essential in environments requiring stringent documentation for safety and regulatory compliance. Users can verify that every joint meets the necessary criteria, fostering trust with stakeholders concerned about adherence to strict guidelines. From a product perspective, selecting a high-quality electrofusion pipe welder enhances operational efficiency. Features such as automated processes, user-friendly interfaces, and low maintenance requirements reduce downtime and operational costs. These benefits are especially pertinent in large-scale projects where time and cost efficiency are pivotal to maintaining budgetary constraints. Electrofusion technology is environmentally considerate, aligning with growing global emphasis on sustainable practices. By minimizing the need for manual intervention and the production of wasted material, operational carbon footprints can be reduced. This aligns with corporate social and environmental responsibility agendas and improves brand perception among increasingly environmentally aware consumers and partners. Investors and stakeholders evaluating the addition of an electrofusion pipe welder into their infrastructure should consider the long-term savings and reliability it provides. The upfront investment is offset by reduced repairs, enhanced safety, and the prestige of utilizing state-of-the-art technology. These outcomes build a compelling case for adopting electrofusion technology, ensuring clients receive nothing short of excellence in service. In conclusion, the adoption of an electrofusion pipe welder in pipeline operations streamlines processes, ensures high integrity joins, complies with rigorous standards, and upholds environmentally sustainable practices, all crucial metrics for gaining a competitive edge. As a sophisticated, effective, and reliable tool, it sets the standard for modern pipe welding, proving to be an investment that pays for itself through enhanced durability and client satisfaction.

Moreover, the controlled nature of the electrofusion process eliminates many variables that can undermine welding reliability. Each weld is recorded in a data log, allowing for transparency and traceability which is essential in environments requiring stringent documentation for safety and regulatory compliance. Users can verify that every joint meets the necessary criteria, fostering trust with stakeholders concerned about adherence to strict guidelines. From a product perspective, selecting a high-quality electrofusion pipe welder enhances operational efficiency. Features such as automated processes, user-friendly interfaces, and low maintenance requirements reduce downtime and operational costs. These benefits are especially pertinent in large-scale projects where time and cost efficiency are pivotal to maintaining budgetary constraints. Electrofusion technology is environmentally considerate, aligning with growing global emphasis on sustainable practices. By minimizing the need for manual intervention and the production of wasted material, operational carbon footprints can be reduced. This aligns with corporate social and environmental responsibility agendas and improves brand perception among increasingly environmentally aware consumers and partners. Investors and stakeholders evaluating the addition of an electrofusion pipe welder into their infrastructure should consider the long-term savings and reliability it provides. The upfront investment is offset by reduced repairs, enhanced safety, and the prestige of utilizing state-of-the-art technology. These outcomes build a compelling case for adopting electrofusion technology, ensuring clients receive nothing short of excellence in service. In conclusion, the adoption of an electrofusion pipe welder in pipeline operations streamlines processes, ensures high integrity joins, complies with rigorous standards, and upholds environmentally sustainable practices, all crucial metrics for gaining a competitive edge. As a sophisticated, effective, and reliable tool, it sets the standard for modern pipe welding, proving to be an investment that pays for itself through enhanced durability and client satisfaction.

Latest News

-

The Rise of Laser Welding: Precision Meets Power in Modern MetalworkNewsAug.06,2025

-

Streamlining Industrial Packaging: The Power of Barrel Production LinesNewsAug.06,2025

-

Revolutionizing Metal Joining: The Power of Automatic Seam Welding MachinesNewsAug.06,2025

-

Powering Industrial Innovation: The Role of Pipe and Tube Machinery in Modern ManufacturingNewsAug.06,2025

-

Exploring the World of Resistance Welding: Equipment, Manufacturers, and Pricing InsightsNewsAug.06,2025

-

Advancing Container Manufacturing: The Role of the Modern Can Welding MachineNewsAug.06,2025

-

Understanding Automatic Seam Welding Machines: A Game Changer in Welding TechnologyNewsJul.18,2025

related products

-

Pneumatic Handle Welding MachineSep . 13, 2024

Pneumatic Handle Welding MachineSep . 13, 2024 -

Fully Automatic Kaiping Production LineOct . 17, 2024

Fully Automatic Kaiping Production LineOct . 17, 2024 -

Fully Automatic Metal Bucket Lifting HeadphonesSep . 14, 2024

Fully Automatic Metal Bucket Lifting HeadphonesSep . 14, 2024