-

8613931787312

8613931787312 -

Botou Industrial Zone on the east side of National Highway 104, Botou City, Hebei Province

Botou Industrial Zone on the east side of National Highway 104, Botou City, Hebei Province

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- haitian_creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- scottish-gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

شوبات . 17, 2025 16:23

Back to list

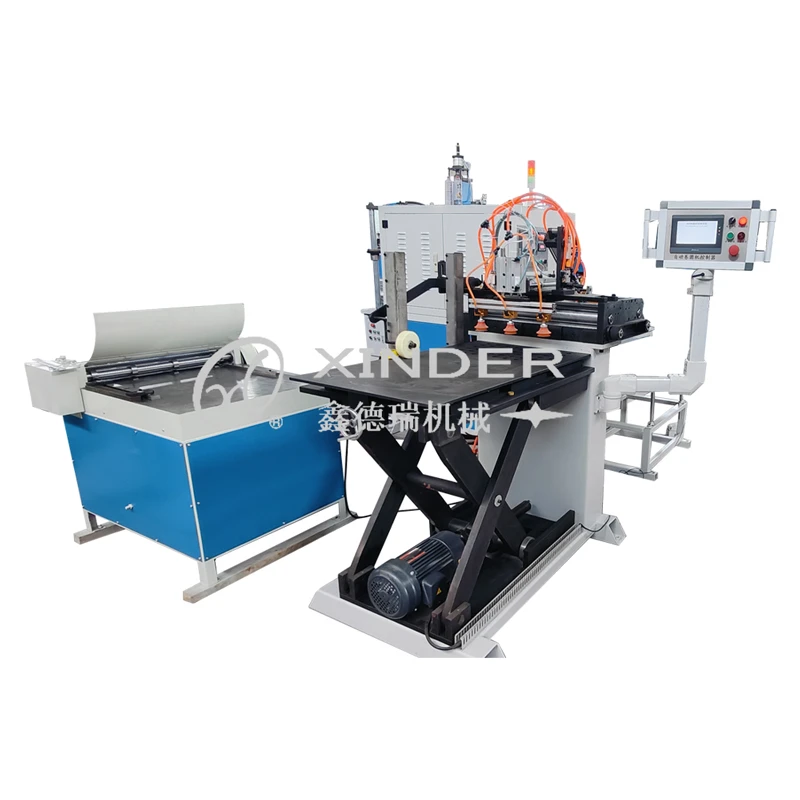

hot forming elbow machine

In the heart of advanced manufacturing technologies, the hot forming elbow machine stands as a beacon of innovation and efficiency. With the pressing demand for high-quality piping components in industries such as oil and gas, construction, and shipbuilding, the expertise encapsulated in these machines has become invaluable. They are engineered to facilitate the seamless production of elbows that integrate perfectly into complex pipe systems, ensuring fluid dynamics work effortlessly without hindrance.

Furthermore, the user interface of modern hot forming elbow machines underscores their trustworthiness and ease of use. It typically features advanced software that allows for the seamless translation of design blueprints into tangible products. This integration minimizes human error and speeds up the production process, providing consistent quality in every batch. Moreover, the tedious maintenance routines are considerably reduced due to innovative self-diagnostic tools that predict wear and necessary adjustments—ensuring prolonged operational effectiveness. From an authoritative standpoint, manufacturers of these machines have led industry standards in ensuring safety and compliance. The continued evolution of safety features guarantees operators are shielded from potential hazards, thus endorsing a culture of safety alongside productivity. These machines not only meet but often exceed the stringent quality standards set by international bodies, reinforcing their position as leading products in the global market. The investment in a hot forming elbow machine is justifiable by the unmatched accuracy, efficiency, and durability they offer. Businesses looking to maintain a competitive edge in industries reliant on sophisticated piping solutions find these machines indispensable. They are a testament to human ingenuity combining scientific knowledge with practical application, ensuring the smooth unraveling of complex industrial challenges. In summary, the hot forming elbow machine is a cornerstone in the modern industrial landscape, supported by authentic expertise and authoritative manufacturing, a symbol of reliability and excellence in engineering solutions.

Furthermore, the user interface of modern hot forming elbow machines underscores their trustworthiness and ease of use. It typically features advanced software that allows for the seamless translation of design blueprints into tangible products. This integration minimizes human error and speeds up the production process, providing consistent quality in every batch. Moreover, the tedious maintenance routines are considerably reduced due to innovative self-diagnostic tools that predict wear and necessary adjustments—ensuring prolonged operational effectiveness. From an authoritative standpoint, manufacturers of these machines have led industry standards in ensuring safety and compliance. The continued evolution of safety features guarantees operators are shielded from potential hazards, thus endorsing a culture of safety alongside productivity. These machines not only meet but often exceed the stringent quality standards set by international bodies, reinforcing their position as leading products in the global market. The investment in a hot forming elbow machine is justifiable by the unmatched accuracy, efficiency, and durability they offer. Businesses looking to maintain a competitive edge in industries reliant on sophisticated piping solutions find these machines indispensable. They are a testament to human ingenuity combining scientific knowledge with practical application, ensuring the smooth unraveling of complex industrial challenges. In summary, the hot forming elbow machine is a cornerstone in the modern industrial landscape, supported by authentic expertise and authoritative manufacturing, a symbol of reliability and excellence in engineering solutions.

Prev:

Next:

Latest News

-

The Rise of Laser Welding: Precision Meets Power in Modern MetalworkNewsAug.06,2025

-

Streamlining Industrial Packaging: The Power of Barrel Production LinesNewsAug.06,2025

-

Revolutionizing Metal Joining: The Power of Automatic Seam Welding MachinesNewsAug.06,2025

-

Powering Industrial Innovation: The Role of Pipe and Tube Machinery in Modern ManufacturingNewsAug.06,2025

-

Exploring the World of Resistance Welding: Equipment, Manufacturers, and Pricing InsightsNewsAug.06,2025

-

Advancing Container Manufacturing: The Role of the Modern Can Welding MachineNewsAug.06,2025

-

Understanding Automatic Seam Welding Machines: A Game Changer in Welding TechnologyNewsJul.18,2025

related products

-

Pneumatic Handle Welding MachineSep . 13, 2024

Pneumatic Handle Welding MachineSep . 13, 2024 -

Fully Automatic Kaiping Production LineOct . 17, 2024

Fully Automatic Kaiping Production LineOct . 17, 2024 -

Fully Automatic Metal Bucket Lifting HeadphonesSep . 14, 2024

Fully Automatic Metal Bucket Lifting HeadphonesSep . 14, 2024