-

8613931787312

8613931787312 -

Botou Industrial Zone on the east side of National Highway 104, Botou City, Hebei Province

Botou Industrial Zone on the east side of National Highway 104, Botou City, Hebei Province

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- haitian_creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- scottish-gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

1월 . 15, 2025 04:08

Back to list

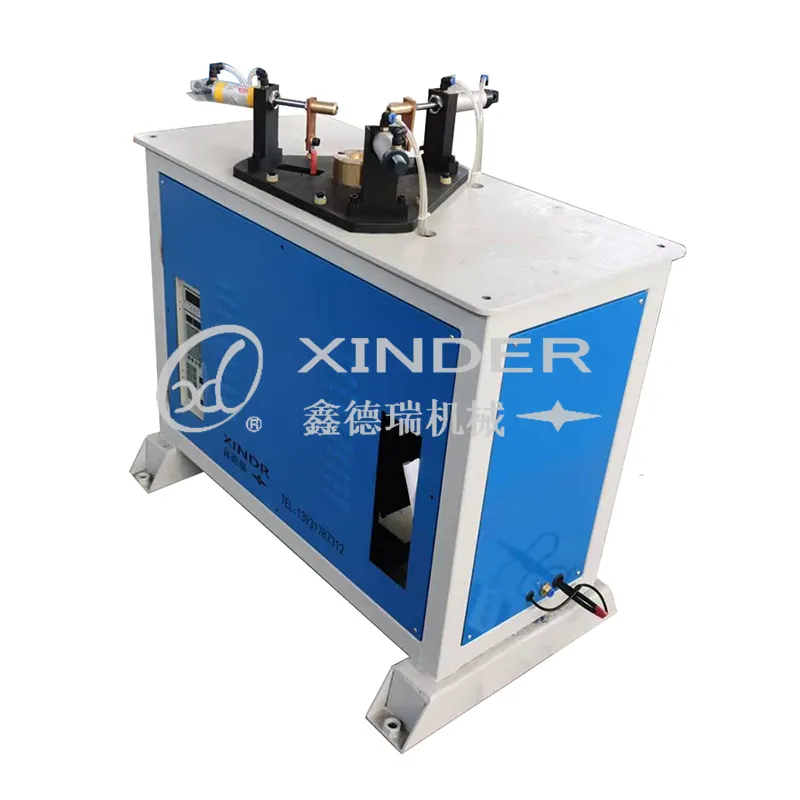

Small Can Seam Welding Machine

The convergence of laser cutting and welding technology has revolutionized the manufacturing industry, offering unparalleled precision, speed, and versatility. As an experienced SEO specialist, I aim to empower manufacturers and fabricators with valuable insights into utilizing laser cutter welders to optimize their operations.

Authoritativeness in laser cutter welding is reflected in the ability to keep up with industry advancements and trends. Engaging with industry forums, technical bulletins, and peer-reviewed journals provides invaluable insight into new technologies and methodologies. Companies that align their services with the latest advancements build a reputation of innovation and reliability, attracting a clientele that values cutting-edge solutions. Establishing trustworthiness in this domain involves more than just technical expertise; it requires a commitment to safety and quality assurance. Laser cutter welders inherently carry risks, such as intense light exposure and material fume emission. Adhering to stringent safety regulations, such as wearing protective gear and ensuring proper ventilation, is non-negotiable. Additionally, implementing robust quality control measures ensures that every fabricated part meets the highest standards. Adding to this, the environmental impact of manufacturing processes cannot be overlooked. Laser cutter welders significantly reduce material waste compared to traditional cutting and welding methods. Their precision minimizes excess material loss, promoting a more sustainable manufacturing approach—a crucial aspect for companies striving for eco-friendly certifications. In conclusion, the integration of laser cutter welders into manufacturing operations offers a multitude of benefits, from enhanced efficiency and precision to environmental sustainability. Companies that invest in this technology and understand its complexities will find themselves at a competitive advantage. As the industry continues to evolve, staying informed about technological advancements and maintaining rigorous safety and quality standards will ensure continued success and reliability in this dynamic field.

Authoritativeness in laser cutter welding is reflected in the ability to keep up with industry advancements and trends. Engaging with industry forums, technical bulletins, and peer-reviewed journals provides invaluable insight into new technologies and methodologies. Companies that align their services with the latest advancements build a reputation of innovation and reliability, attracting a clientele that values cutting-edge solutions. Establishing trustworthiness in this domain involves more than just technical expertise; it requires a commitment to safety and quality assurance. Laser cutter welders inherently carry risks, such as intense light exposure and material fume emission. Adhering to stringent safety regulations, such as wearing protective gear and ensuring proper ventilation, is non-negotiable. Additionally, implementing robust quality control measures ensures that every fabricated part meets the highest standards. Adding to this, the environmental impact of manufacturing processes cannot be overlooked. Laser cutter welders significantly reduce material waste compared to traditional cutting and welding methods. Their precision minimizes excess material loss, promoting a more sustainable manufacturing approach—a crucial aspect for companies striving for eco-friendly certifications. In conclusion, the integration of laser cutter welders into manufacturing operations offers a multitude of benefits, from enhanced efficiency and precision to environmental sustainability. Companies that invest in this technology and understand its complexities will find themselves at a competitive advantage. As the industry continues to evolve, staying informed about technological advancements and maintaining rigorous safety and quality standards will ensure continued success and reliability in this dynamic field.

Latest News

-

Understanding Resistance Welding: Equipment, Manufacturers, and PricingNewsMay.15,2025

-

Understanding Pneumatic Welding Machines: Types, Applications, and AdvantagesNewsMay.15,2025

-

Exploring Tube Benders: Types, Manufacturers, and ApplicationsNewsMay.15,2025

-

Exploring Metal Pipe Machines: Types, Functions, and ApplicationsNewsMay.15,2025

-

Exploring Laser Welding Machines: Key Manufacturers, Technology, and ApplicationsNewsMay.15,2025

-

Exploring Barrel Production Lines: Machines, Pricing, and Manufacturing ProcessNewsMay.15,2025

-

The Role of Steel Pipe Manufacturing Machines in Modern IndustriesNewsApr.18,2025

related products

-

Fully Automatic Kaiping Production LineOct . 17, 2024

Fully Automatic Kaiping Production LineOct . 17, 2024 -

Fully Automatic Metal Bucket Lifting HeadphonesSep . 14, 2024

Fully Automatic Metal Bucket Lifting HeadphonesSep . 14, 2024 -

Automatic Rolling MachineSep . 14, 2024

Automatic Rolling MachineSep . 14, 2024