-

8613931787312

8613931787312 -

Botou Industrial Zone on the east side of National Highway 104, Botou City, Hebei Province

Botou Industrial Zone on the east side of National Highway 104, Botou City, Hebei Province

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- haitian_creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- scottish-gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

ಫೆಬ್ರ . 18, 2025 03:39

Back to list

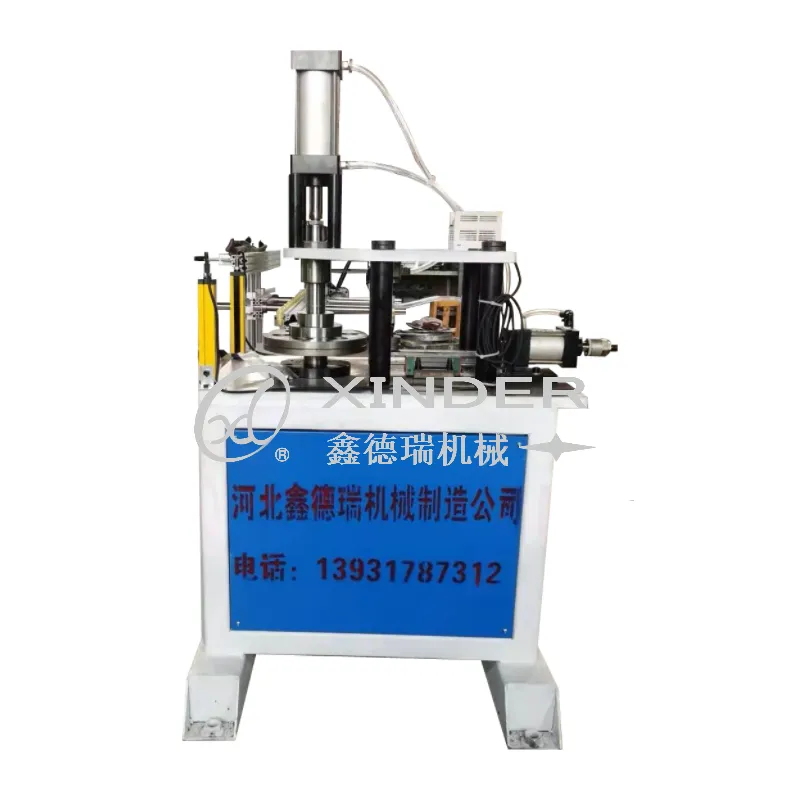

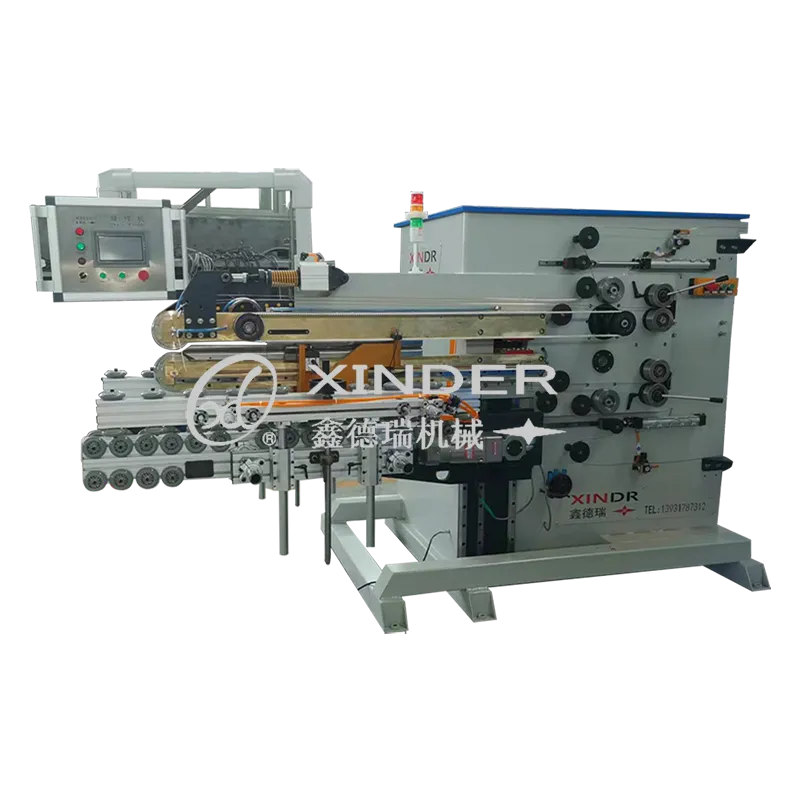

cylindrical seam welding machine

In the ever-evolving industry of welding technology, cylindrical seam welding machines stand out as a pivotal advancement, continuously transforming how industrial tasks are carried out. These machines are engineered to provide precision, stability, and efficiency in welding cylindrical components, offering unparalleled advantages to manufacturers across various sectors.

The specialized design of cylindrical seam welding machines offers several key advantages over conventional welding techniques. Their capability to weld around cylindrical parts with uninterrupted seam lines is crucial in applications like tank and pipe manufacturing, where leak-proof and structurally sound welds are vital. This characteristic not only improves the integrity and longevity of the products but also aligns with rigorous safety and performance criteria prevalent in modern manufacturing. In manufacturing environments where precision and efficiency are paramount, cylindrical seam welding machines bring an automated solution that addresses both. By reducing manual labor and potential human error, these machines heighten overall manufacturing quality. Furthermore, the welding speed and accuracy provided streamline operations, allowing manufacturers to meet tight deadlines without compromising weld quality. Additionally, the automation incorporated in these machines opens up new possibilities for large-scale production runs without the need for constant human supervision. As sustainability becomes a pressing concern across industries, cylindrical seam welding machines contribute to this movement by reducing waste and energy consumption. By ensuring precise control over welding parameters and minimizing material usage, these machines align with environmental goals and sustainability initiatives, a growing priority for modern businesses. In conclusion, cylindrical seam welding machines are more than just additions to the welding landscape; they are transformative tools that encapsulate the essence of technological advancement in industrial applications. Their precision, efficiency, and adaptability make them indispensable in sectors requiring high-quality welds and rapid production cycles. As manufacturers continue to prioritize innovation, the capabilities of cylindrical seam welding machines will undoubtedly expand, further cementing their role in shaping the future of welding technology.

The specialized design of cylindrical seam welding machines offers several key advantages over conventional welding techniques. Their capability to weld around cylindrical parts with uninterrupted seam lines is crucial in applications like tank and pipe manufacturing, where leak-proof and structurally sound welds are vital. This characteristic not only improves the integrity and longevity of the products but also aligns with rigorous safety and performance criteria prevalent in modern manufacturing. In manufacturing environments where precision and efficiency are paramount, cylindrical seam welding machines bring an automated solution that addresses both. By reducing manual labor and potential human error, these machines heighten overall manufacturing quality. Furthermore, the welding speed and accuracy provided streamline operations, allowing manufacturers to meet tight deadlines without compromising weld quality. Additionally, the automation incorporated in these machines opens up new possibilities for large-scale production runs without the need for constant human supervision. As sustainability becomes a pressing concern across industries, cylindrical seam welding machines contribute to this movement by reducing waste and energy consumption. By ensuring precise control over welding parameters and minimizing material usage, these machines align with environmental goals and sustainability initiatives, a growing priority for modern businesses. In conclusion, cylindrical seam welding machines are more than just additions to the welding landscape; they are transformative tools that encapsulate the essence of technological advancement in industrial applications. Their precision, efficiency, and adaptability make them indispensable in sectors requiring high-quality welds and rapid production cycles. As manufacturers continue to prioritize innovation, the capabilities of cylindrical seam welding machines will undoubtedly expand, further cementing their role in shaping the future of welding technology.

Latest News

-

The Rise of Laser Welding in Global Manufacturing: Spotlight on China’s Competitive EdgeNewsJun.05,2025

-

The Power of Precision: Exploring the Role of Automatic Seam Welding Machines in Modern ManufacturingNewsJun.05,2025

-

The Essential Guide to Can Welding Machines: Revolutionizing the Packaging IndustryNewsJun.05,2025

-

Resistance Welding Equipment: A Smart Investment for Industrial ManufacturingNewsJun.05,2025

-

Precision Welding for Modern Manufacturing: The Rise of Automatic Seam Welding MachinesNewsJun.05,2025

-

Laser Welding for Stainless Steel: The Precision Edge in Modern Metal FabricationNewsJun.05,2025

-

The Modern Evolution of Barrel Production: Technology, Machines, and Market PricingNewsMay.22,2025

related products

-

Fully Automatic Kaiping Production LineOct . 17, 2024

Fully Automatic Kaiping Production LineOct . 17, 2024 -

Fully Automatic Metal Bucket Lifting HeadphonesSep . 14, 2024

Fully Automatic Metal Bucket Lifting HeadphonesSep . 14, 2024 -

Automatic Rolling MachineSep . 14, 2024

Automatic Rolling MachineSep . 14, 2024