-

8613931787312

8613931787312 -

Botou Industrial Zone on the east side of National Highway 104, Botou City, Hebei Province

Botou Industrial Zone on the east side of National Highway 104, Botou City, Hebei Province

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- haitian_creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- scottish-gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

ಜನ . 10, 2025 08:26

Back to list

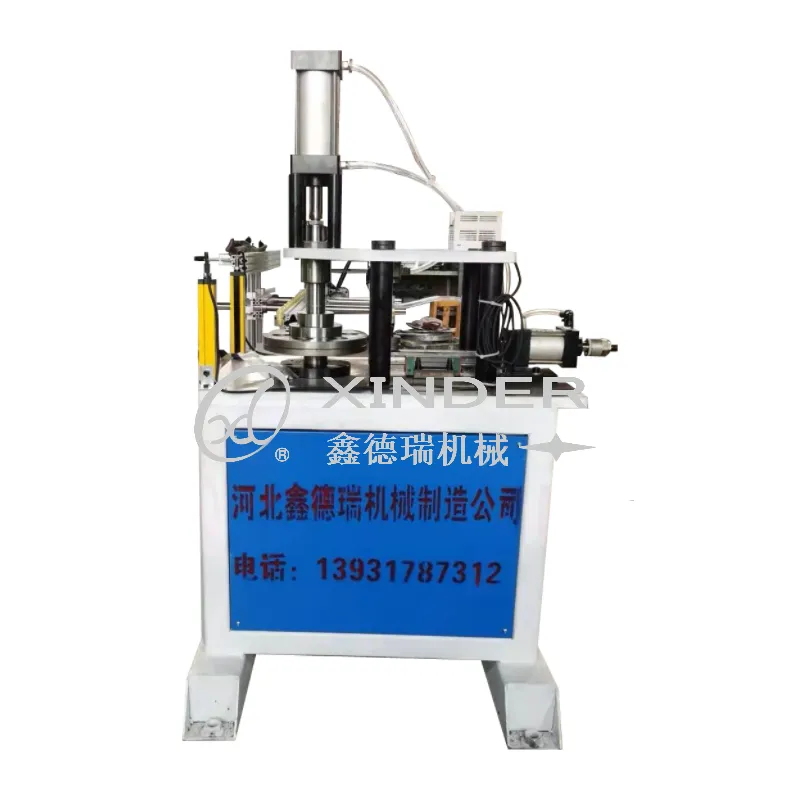

chief resistance welder

A chief resistance welder stands as a cornerstone in modern manufacturing, especially in industries where precision and strength are paramount. This sophisticated machinery, essential for efficiency and quality in production lines, melds technical expertise with practical innovation, providing manufacturers with reliable and high-performance tools.

Authoritativeness in the realm of resistance welding often comes from institutions and companies that have set the standards for the industry. Organizations like the American Welding Society (AWS) provide certifications and qualifications that validate skills in handling such high-precision equipment. Development and research programs within companies producing these welders continually push the boundaries of what's possible, contributing to industry-wide benchmarks for quality and safety. Trustworthiness is built over time, and in the field of chief resistance welding, it’s exemplified by the long-standing relationships between manufacturers and their clients. Testimonials from leading manufacturers, who depend on these welders for the integrity of their production lines, reinforce the reliability and necessity of these machines. Feedback loops between users and developers enhance the welders’ design, ensuring they meet the evolving needs of the industry while maintaining safety and quality. Investing in a chief resistance welder is not just a commitment to a piece of equipment; it's a dedication to producing exceptional products consistently. Each welder is a testament to human ingenuity, engineering prowess, and the unyielding demand for quality and reliability in the manufacturing process. For businesses aiming to lead with precision, trust, and expertise, integrating a chief resistance welder into their production line is not just a choice, but a strategic imperative.

Authoritativeness in the realm of resistance welding often comes from institutions and companies that have set the standards for the industry. Organizations like the American Welding Society (AWS) provide certifications and qualifications that validate skills in handling such high-precision equipment. Development and research programs within companies producing these welders continually push the boundaries of what's possible, contributing to industry-wide benchmarks for quality and safety. Trustworthiness is built over time, and in the field of chief resistance welding, it’s exemplified by the long-standing relationships between manufacturers and their clients. Testimonials from leading manufacturers, who depend on these welders for the integrity of their production lines, reinforce the reliability and necessity of these machines. Feedback loops between users and developers enhance the welders’ design, ensuring they meet the evolving needs of the industry while maintaining safety and quality. Investing in a chief resistance welder is not just a commitment to a piece of equipment; it's a dedication to producing exceptional products consistently. Each welder is a testament to human ingenuity, engineering prowess, and the unyielding demand for quality and reliability in the manufacturing process. For businesses aiming to lead with precision, trust, and expertise, integrating a chief resistance welder into their production line is not just a choice, but a strategic imperative.

Latest News

-

Understanding Resistance Welding: Equipment, Manufacturers, and PricingNewsMay.15,2025

-

Understanding Pneumatic Welding Machines: Types, Applications, and AdvantagesNewsMay.15,2025

-

Exploring Tube Benders: Types, Manufacturers, and ApplicationsNewsMay.15,2025

-

Exploring Metal Pipe Machines: Types, Functions, and ApplicationsNewsMay.15,2025

-

Exploring Laser Welding Machines: Key Manufacturers, Technology, and ApplicationsNewsMay.15,2025

-

Exploring Barrel Production Lines: Machines, Pricing, and Manufacturing ProcessNewsMay.15,2025

-

The Role of Steel Pipe Manufacturing Machines in Modern IndustriesNewsApr.18,2025

related products

-

Fully Automatic Kaiping Production LineOct . 17, 2024

Fully Automatic Kaiping Production LineOct . 17, 2024 -

Fully Automatic Metal Bucket Lifting HeadphonesSep . 14, 2024

Fully Automatic Metal Bucket Lifting HeadphonesSep . 14, 2024 -

Automatic Rolling MachineSep . 14, 2024

Automatic Rolling MachineSep . 14, 2024