-

8613931787312

8613931787312 -

Botou Industrial Zone on the east side of National Highway 104, Botou City, Hebei Province

Botou Industrial Zone on the east side of National Highway 104, Botou City, Hebei Province

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- haitian_creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- scottish-gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

თებ . 18, 2025 02:27

Back to list

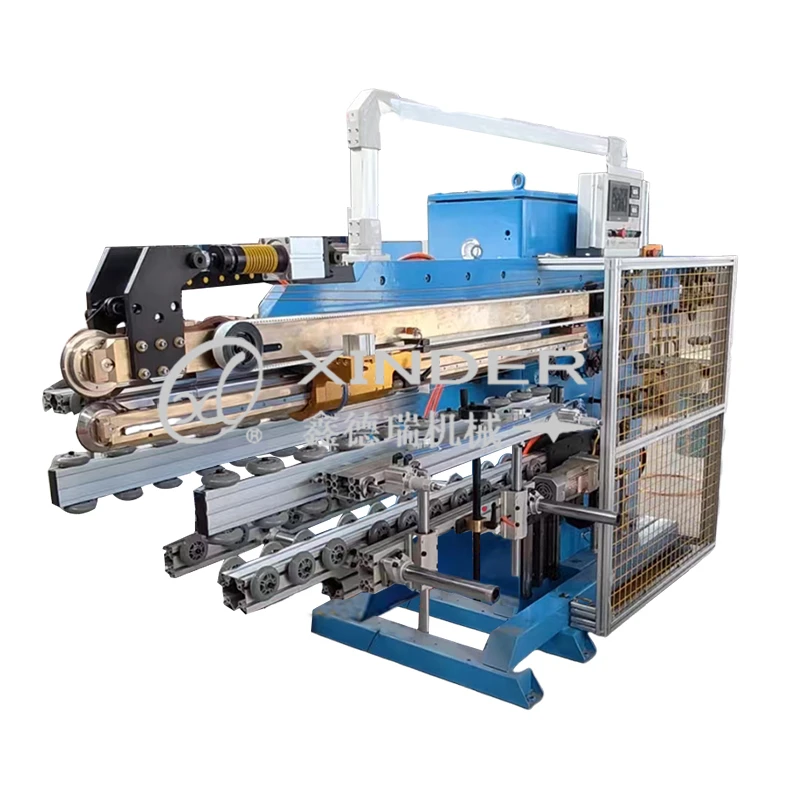

Fully Automatic Steel Barrel Straight Seam Laser Welding Machine

In the realm of modern manufacturing, the stainless steel laser tube making machine stands as a cornerstone of technological advancement. Within the bustling environment of production facilities, the evolution of these machines has not only transformed efficiency but also redefined quality standards across industries.

The advent of stainless steel laser tube making machines has also led to a diversification of product designs. The flexibility of laser technology allows for intricate patterns and shapes, previously unattainable with conventional methods. This creative freedom not only enhances product aesthetics but also functional aspects, enabling designs that maximize efficiency and performance in their respective applications. Manufacturers utilizing stainless steel laser tube making machines gain a competitive edge through reduced lead times and the capacity to quickly adapt to market demands. The machines’ software capabilities enable rapid prototyping and easy adjustments, which are critical in industries experiencing fast-paced advancements and innovation demands. The ability to quickly transition from one design to another without extensive downtime transforms the manufacturer’s ability to respond to customer needs swiftly. Lastly, the economic implications cannot be overstated. Although the initial investment in a stainless steel laser tube making machine is substantial, the long-term cost-benefit ratio is favorable. Reduced material waste, minimal maintenance costs due to the durability of lasers, and the lower need for manual labor translate into significant savings over time. Moreover, the high-speed capabilities contribute to increased output rates, ensuring that operational efficiency is maximized. In summary, stainless steel laser tube making machines embody the future of efficient, high-quality manufacturing. Their ability to merge precision, reliability, and flexibility with economic and sustainable practices positions them as indispensable assets in the ever-evolving landscape of industrial production. As industries continue to push the boundaries of innovation, these machines will undoubtedly remain at the forefront, shaping the benchmarks of modern manufacturing excellence.

The advent of stainless steel laser tube making machines has also led to a diversification of product designs. The flexibility of laser technology allows for intricate patterns and shapes, previously unattainable with conventional methods. This creative freedom not only enhances product aesthetics but also functional aspects, enabling designs that maximize efficiency and performance in their respective applications. Manufacturers utilizing stainless steel laser tube making machines gain a competitive edge through reduced lead times and the capacity to quickly adapt to market demands. The machines’ software capabilities enable rapid prototyping and easy adjustments, which are critical in industries experiencing fast-paced advancements and innovation demands. The ability to quickly transition from one design to another without extensive downtime transforms the manufacturer’s ability to respond to customer needs swiftly. Lastly, the economic implications cannot be overstated. Although the initial investment in a stainless steel laser tube making machine is substantial, the long-term cost-benefit ratio is favorable. Reduced material waste, minimal maintenance costs due to the durability of lasers, and the lower need for manual labor translate into significant savings over time. Moreover, the high-speed capabilities contribute to increased output rates, ensuring that operational efficiency is maximized. In summary, stainless steel laser tube making machines embody the future of efficient, high-quality manufacturing. Their ability to merge precision, reliability, and flexibility with economic and sustainable practices positions them as indispensable assets in the ever-evolving landscape of industrial production. As industries continue to push the boundaries of innovation, these machines will undoubtedly remain at the forefront, shaping the benchmarks of modern manufacturing excellence.

Latest News

-

The Rise of Laser Welding: Precision Meets Power in Modern MetalworkNewsAug.06,2025

-

Streamlining Industrial Packaging: The Power of Barrel Production LinesNewsAug.06,2025

-

Revolutionizing Metal Joining: The Power of Automatic Seam Welding MachinesNewsAug.06,2025

-

Powering Industrial Innovation: The Role of Pipe and Tube Machinery in Modern ManufacturingNewsAug.06,2025

-

Exploring the World of Resistance Welding: Equipment, Manufacturers, and Pricing InsightsNewsAug.06,2025

-

Advancing Container Manufacturing: The Role of the Modern Can Welding MachineNewsAug.06,2025

-

Understanding Automatic Seam Welding Machines: A Game Changer in Welding TechnologyNewsJul.18,2025

related products

-

Pneumatic Handle Welding MachineSep . 13, 2024

Pneumatic Handle Welding MachineSep . 13, 2024 -

Fully Automatic Kaiping Production LineOct . 17, 2024

Fully Automatic Kaiping Production LineOct . 17, 2024 -

Fully Automatic Metal Bucket Lifting HeadphonesSep . 14, 2024

Fully Automatic Metal Bucket Lifting HeadphonesSep . 14, 2024