-

8613931787312

8613931787312 -

Botou Industrial Zone on the east side of National Highway 104, Botou City, Hebei Province

Botou Industrial Zone on the east side of National Highway 104, Botou City, Hebei Province

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- haitian_creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- scottish-gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Feb . 16, 2025 03:19

Back to list

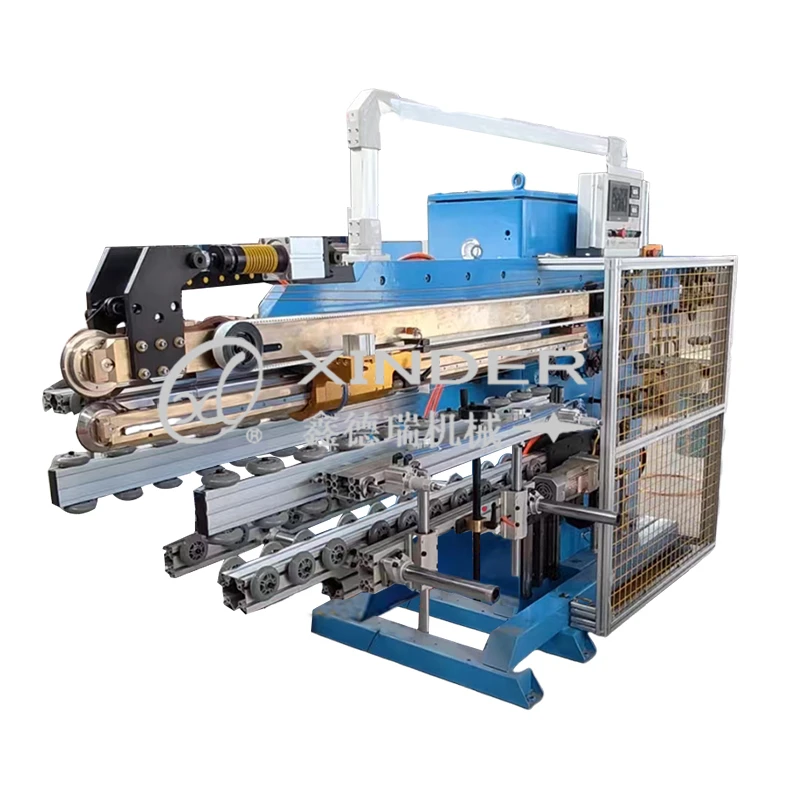

Fully Automatic Welded Pipe Machine

Mastering the Art of Polypropylene Pipe Welding A Deep Dive into the Essential Machine

Real-world Applications Experience Matters Experienced professionals recognize that not all welding scenarios are identical. The context in which the polypropylene piping will function impacts the welding approach. For instance, pipes intended for outdoor use require considerations for UV exposure, necessitating UV-stabilized materials. Indoor plumbing may focus more on joint aesthetics. Seasoned technicians provide invaluable insights, drawing from years of fieldwork to ensure that the welding approach successfully navigates real-world conditions. Trustworthiness Through Ongoing Support and Training The best providers of polypropylene pipe welding machines offer ongoing support and training, cementing their credibility and reliability. Continuous education initiatives, such as workshops and online tutorials, ensure that operators stay abreast of the latest techniques and safety protocols. This support system is vital, fostering not only better workflow efficiencies but also contributing to the professional development of the technicians who rely on these machines daily. New Innovations Shaping the Future of Polypropylene Pipe Welding Advancements in technology continue to enhance the capabilities of polypropylene pipe welding machines. Future innovations may include smart connectivity for real-time monitoring and diagnostics, enhancing operational oversight and predictive maintenance. Additionally, integration with augmented reality could provide enhanced training experiences, offering step-by-step, immersive guidance for novice operators and veterans alike. Concluding the Polypropylene Pipe Welding Journey In summary, polypropylene pipe welding machines stand as pivotal instruments in the sphere of modern plumbing and construction. Their ability to seamlessly fuse pipes speaks to a blend of precision engineering and technological prowess, underpinned by safety and practical expertise. Whether navigating new projects or maintaining existing systems, these machines embody engineering excellence and reliability essential for modern infrastructure. Selecting the right machine and approach necessitates a deep understanding of not only the equipment but the context of its application, ensuring a harmonious balance between expertise and trust.

Real-world Applications Experience Matters Experienced professionals recognize that not all welding scenarios are identical. The context in which the polypropylene piping will function impacts the welding approach. For instance, pipes intended for outdoor use require considerations for UV exposure, necessitating UV-stabilized materials. Indoor plumbing may focus more on joint aesthetics. Seasoned technicians provide invaluable insights, drawing from years of fieldwork to ensure that the welding approach successfully navigates real-world conditions. Trustworthiness Through Ongoing Support and Training The best providers of polypropylene pipe welding machines offer ongoing support and training, cementing their credibility and reliability. Continuous education initiatives, such as workshops and online tutorials, ensure that operators stay abreast of the latest techniques and safety protocols. This support system is vital, fostering not only better workflow efficiencies but also contributing to the professional development of the technicians who rely on these machines daily. New Innovations Shaping the Future of Polypropylene Pipe Welding Advancements in technology continue to enhance the capabilities of polypropylene pipe welding machines. Future innovations may include smart connectivity for real-time monitoring and diagnostics, enhancing operational oversight and predictive maintenance. Additionally, integration with augmented reality could provide enhanced training experiences, offering step-by-step, immersive guidance for novice operators and veterans alike. Concluding the Polypropylene Pipe Welding Journey In summary, polypropylene pipe welding machines stand as pivotal instruments in the sphere of modern plumbing and construction. Their ability to seamlessly fuse pipes speaks to a blend of precision engineering and technological prowess, underpinned by safety and practical expertise. Whether navigating new projects or maintaining existing systems, these machines embody engineering excellence and reliability essential for modern infrastructure. Selecting the right machine and approach necessitates a deep understanding of not only the equipment but the context of its application, ensuring a harmonious balance between expertise and trust.

Prev:

Latest News

-

The Rise of Laser Welding: Precision Meets Power in Modern MetalworkNewsAug.06,2025

-

Streamlining Industrial Packaging: The Power of Barrel Production LinesNewsAug.06,2025

-

Revolutionizing Metal Joining: The Power of Automatic Seam Welding MachinesNewsAug.06,2025

-

Powering Industrial Innovation: The Role of Pipe and Tube Machinery in Modern ManufacturingNewsAug.06,2025

-

Exploring the World of Resistance Welding: Equipment, Manufacturers, and Pricing InsightsNewsAug.06,2025

-

Advancing Container Manufacturing: The Role of the Modern Can Welding MachineNewsAug.06,2025

-

Understanding Automatic Seam Welding Machines: A Game Changer in Welding TechnologyNewsJul.18,2025

related products

-

Pneumatic Handle Welding MachineSep . 13, 2024

Pneumatic Handle Welding MachineSep . 13, 2024 -

Fully Automatic Kaiping Production LineOct . 17, 2024

Fully Automatic Kaiping Production LineOct . 17, 2024 -

Fully Automatic Metal Bucket Lifting HeadphonesSep . 14, 2024

Fully Automatic Metal Bucket Lifting HeadphonesSep . 14, 2024