-

8613931787312

8613931787312 -

Botou Industrial Zone on the east side of National Highway 104, Botou City, Hebei Province

Botou Industrial Zone on the east side of National Highway 104, Botou City, Hebei Province

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- haitian_creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- scottish-gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

1月 . 09, 2025 12:13

Back to list

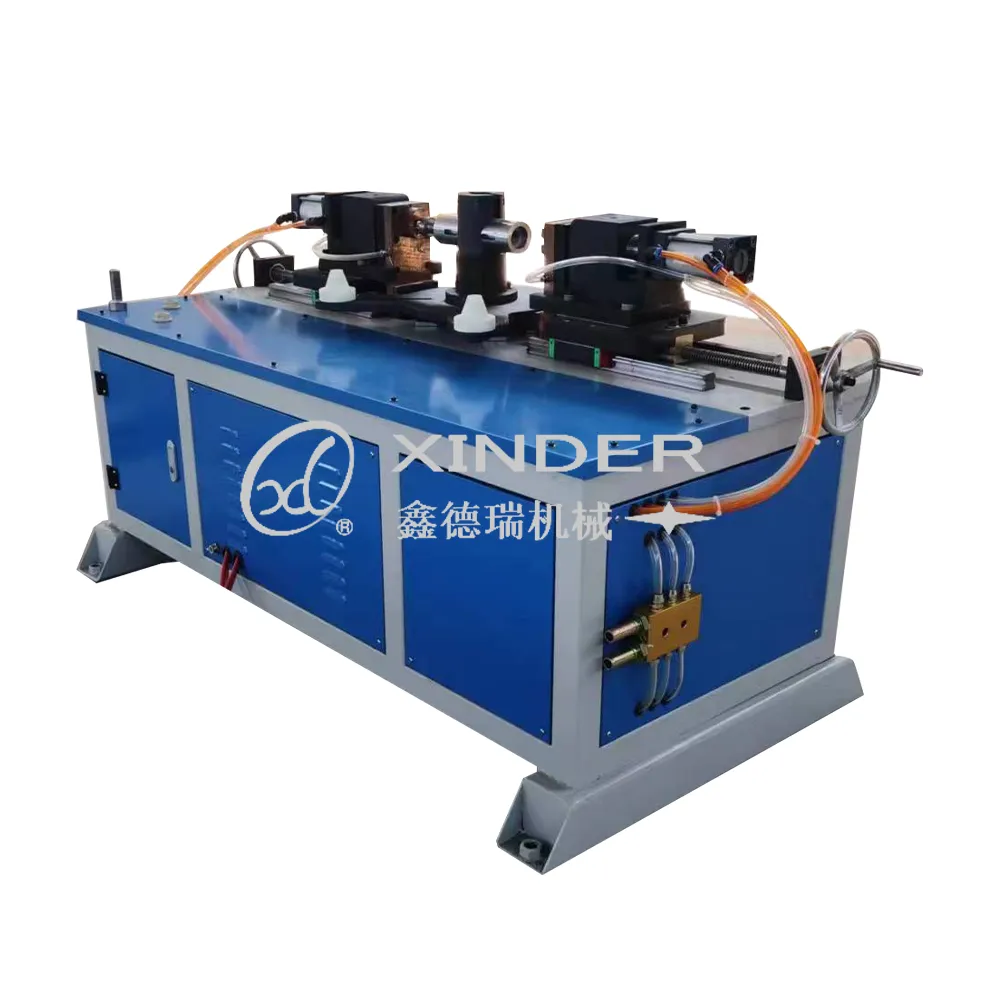

automatic seam welding machine

Navigating the world of resistance welding equipment manufacturers can be an intricate task for businesses seeking efficient and reliable solutions. Understanding the ins and outs of this specialized industry is crucial for making informed purchasing decisions that align with production goals and quality standards.

Product ranges and adaptability are also key considerations. Versatility in their offerings, such as spot, seam, projection, and flash welding machines, allows manufacturers to cater to diverse industrial needs. Additionally, the ability to customize equipment to accommodate specific materials or production lines adds a significant competitive edge. Pioneers like Miyachi Unitek and Amada Weld Tech are known for their cutting-edge welding solutions, combining high-quality craftsmanship with innovative technology designed to offer scalable solutions. These manufacturers have confident portfolios characterized by successful implementations across industries, which can be a useful benchmark when selecting a partner for resistance welding equipment. Furthermore, the commitment to sustainability and energy efficiency is increasingly becoming a crucial element in the evaluation process. Manufacturers that integrate eco-friendly practices and materials not only contribute to environmental conservation efforts but also offer cost-saving benefits by reducing operational energy consumption. Finally, considering regional support capabilities and logistics efficiencies ensures smooth operation and quick response times for maintenance or part replacements. Manufacturers with robust global networks or strong local distributors can provide extensive reach and support, vital for continuous production in today’s fast-paced manufacturing environment. In conclusion, while selecting resistance welding equipment manufacturers, businesses should holistically assess experience, expertise, authoritativeness, and trustworthiness. The decision should align with the company’s quality standards, production goals, and ethical values to find a true partner in manufacturing excellence.

Product ranges and adaptability are also key considerations. Versatility in their offerings, such as spot, seam, projection, and flash welding machines, allows manufacturers to cater to diverse industrial needs. Additionally, the ability to customize equipment to accommodate specific materials or production lines adds a significant competitive edge. Pioneers like Miyachi Unitek and Amada Weld Tech are known for their cutting-edge welding solutions, combining high-quality craftsmanship with innovative technology designed to offer scalable solutions. These manufacturers have confident portfolios characterized by successful implementations across industries, which can be a useful benchmark when selecting a partner for resistance welding equipment. Furthermore, the commitment to sustainability and energy efficiency is increasingly becoming a crucial element in the evaluation process. Manufacturers that integrate eco-friendly practices and materials not only contribute to environmental conservation efforts but also offer cost-saving benefits by reducing operational energy consumption. Finally, considering regional support capabilities and logistics efficiencies ensures smooth operation and quick response times for maintenance or part replacements. Manufacturers with robust global networks or strong local distributors can provide extensive reach and support, vital for continuous production in today’s fast-paced manufacturing environment. In conclusion, while selecting resistance welding equipment manufacturers, businesses should holistically assess experience, expertise, authoritativeness, and trustworthiness. The decision should align with the company’s quality standards, production goals, and ethical values to find a true partner in manufacturing excellence.

Next:

Latest News

-

The Rise of Laser Welding in Global Manufacturing: Spotlight on China’s Competitive EdgeNewsJun.05,2025

-

The Power of Precision: Exploring the Role of Automatic Seam Welding Machines in Modern ManufacturingNewsJun.05,2025

-

The Essential Guide to Can Welding Machines: Revolutionizing the Packaging IndustryNewsJun.05,2025

-

Resistance Welding Equipment: A Smart Investment for Industrial ManufacturingNewsJun.05,2025

-

Precision Welding for Modern Manufacturing: The Rise of Automatic Seam Welding MachinesNewsJun.05,2025

-

Laser Welding for Stainless Steel: The Precision Edge in Modern Metal FabricationNewsJun.05,2025

-

The Modern Evolution of Barrel Production: Technology, Machines, and Market PricingNewsMay.22,2025

related products

-

Pneumatic Handle Welding MachineSep . 13, 2024

Pneumatic Handle Welding MachineSep . 13, 2024 -

Fully Automatic Kaiping Production LineOct . 17, 2024

Fully Automatic Kaiping Production LineOct . 17, 2024 -

Fully Automatic Metal Bucket Lifting HeadphonesSep . 14, 2024

Fully Automatic Metal Bucket Lifting HeadphonesSep . 14, 2024