-

8613931787312

8613931787312 -

Botou Industrial Zone on the east side of National Highway 104, Botou City, Hebei Province

Botou Industrial Zone on the east side of National Highway 104, Botou City, Hebei Province

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- haitian_creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- scottish-gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

mar . 05, 2025 01:39

Back to list

paint bucket production line

Maximizing Efficiency in Paint Bucket Production Lines Insights from Industry Experts

Employee training and investment in skilled labor remain fundamental to the success of production lines. Despite the rise of automation, skilled workers are essential for overseeing operations and handling complex machinery. Comprehensive training programs ensure that employees are proficient in using the latest technology, which enhances productivity and safety. Regular training updates for employees keep the workforce adaptable and prepared to tackle new challenges in production, suggests Laura Smith, an HR manager with extensive experience in industrial training programs. Environmental considerations are also at the forefront of industry advancements. Reducing energy consumption and waste production is crucial for sustainable operations. Many companies are turning to renewable energy sources and implementing waste management protocols to minimize their environmental footprint. The use of energy-efficient machinery not only cuts costs but also aligns with global sustainability goals, ensuring that businesses remain competitive and compliant with environmental legislation. Finally, the importance of quality assurance cannot be overstated. A robust quality control system at every stage of the production line ensures that only the highest quality products reach the market. From initial material inspection to final product testing, maintaining strict quality standards builds brand reputation and customer trust. John Mitchell, a quality assurance guru, asserts, A proactive approach to quality control not only prevents costly recalls but also solidifies long-term customer relationships. In conclusion, the evolution of paint bucket production lines demonstrates a commitment to integrating modern technology, sustainable practices, and skilled labor to create a more efficient and responsible manufacturing process. By leveraging these insights, companies can enhance their production capabilities, meet market demands, and uphold their reputation as leaders in manufacturing innovation.

Employee training and investment in skilled labor remain fundamental to the success of production lines. Despite the rise of automation, skilled workers are essential for overseeing operations and handling complex machinery. Comprehensive training programs ensure that employees are proficient in using the latest technology, which enhances productivity and safety. Regular training updates for employees keep the workforce adaptable and prepared to tackle new challenges in production, suggests Laura Smith, an HR manager with extensive experience in industrial training programs. Environmental considerations are also at the forefront of industry advancements. Reducing energy consumption and waste production is crucial for sustainable operations. Many companies are turning to renewable energy sources and implementing waste management protocols to minimize their environmental footprint. The use of energy-efficient machinery not only cuts costs but also aligns with global sustainability goals, ensuring that businesses remain competitive and compliant with environmental legislation. Finally, the importance of quality assurance cannot be overstated. A robust quality control system at every stage of the production line ensures that only the highest quality products reach the market. From initial material inspection to final product testing, maintaining strict quality standards builds brand reputation and customer trust. John Mitchell, a quality assurance guru, asserts, A proactive approach to quality control not only prevents costly recalls but also solidifies long-term customer relationships. In conclusion, the evolution of paint bucket production lines demonstrates a commitment to integrating modern technology, sustainable practices, and skilled labor to create a more efficient and responsible manufacturing process. By leveraging these insights, companies can enhance their production capabilities, meet market demands, and uphold their reputation as leaders in manufacturing innovation.

Latest News

-

The Rise of Laser Welding: Precision Meets Power in Modern MetalworkNewsAug.06,2025

-

Streamlining Industrial Packaging: The Power of Barrel Production LinesNewsAug.06,2025

-

Revolutionizing Metal Joining: The Power of Automatic Seam Welding MachinesNewsAug.06,2025

-

Powering Industrial Innovation: The Role of Pipe and Tube Machinery in Modern ManufacturingNewsAug.06,2025

-

Exploring the World of Resistance Welding: Equipment, Manufacturers, and Pricing InsightsNewsAug.06,2025

-

Advancing Container Manufacturing: The Role of the Modern Can Welding MachineNewsAug.06,2025

-

Understanding Automatic Seam Welding Machines: A Game Changer in Welding TechnologyNewsJul.18,2025

related products

-

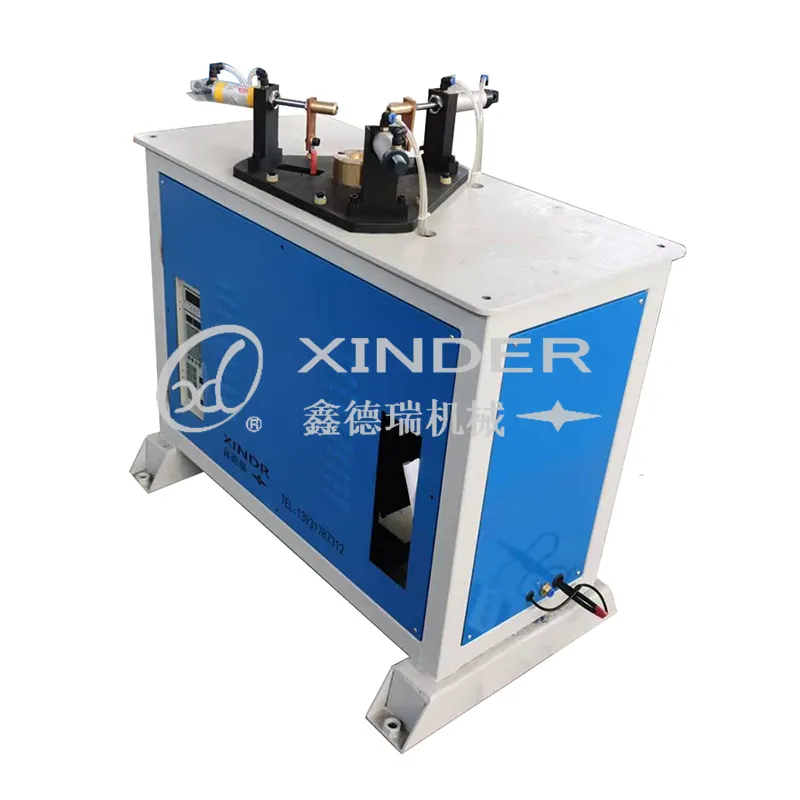

Pneumatic Handle Welding MachineSep . 13, 2024

Pneumatic Handle Welding MachineSep . 13, 2024 -

Fully Automatic Kaiping Production LineOct . 17, 2024

Fully Automatic Kaiping Production LineOct . 17, 2024 -

Fully Automatic Metal Bucket Lifting HeadphonesSep . 14, 2024

Fully Automatic Metal Bucket Lifting HeadphonesSep . 14, 2024