-

8613931787312

8613931787312 -

Botou Industrial Zone on the east side of National Highway 104, Botou City, Hebei Province

Botou Industrial Zone on the east side of National Highway 104, Botou City, Hebei Province

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- haitian_creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- scottish-gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Փտր . 02, 2025 05:43

Back to list

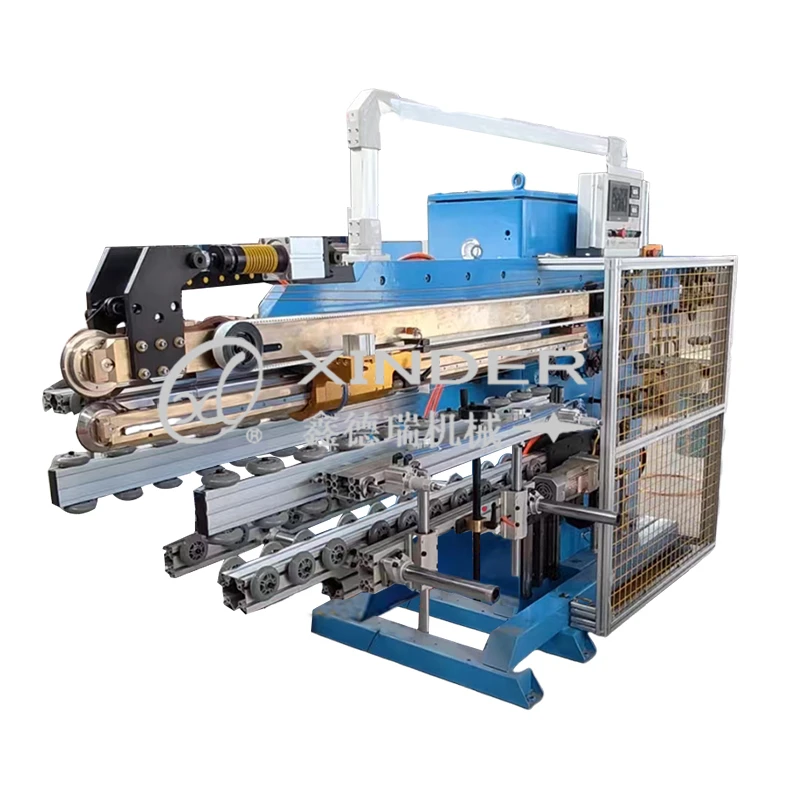

Fully Automatic Pipe Cutting Machine

Investing in a metal shearing machine can significantly enhance your manufacturing process, offering precision, efficiency, and longevity in your operations. As an experienced professional in the machinery industry, understanding the multifaceted benefits and technical aspects of these machines can boost both your productivity and credibility in the marketplace.

Real-world experience reflects that using a metal shearing machine not only saves time and reduces labor costs but also contributes to creating a safer workspace. With proper training and safety gear, the risks associated with manual metal cutting are minimized, leading to a reduction in workplace injuries and boosting overall employee morale. For sectors aiming to ensure sustainable practices, selecting eco-friendly metal shearing machines can also align with corporate social responsibility goals. Machines designed with energy-efficient technology reduce energy consumption, leading to decreased operational costs and a lower carbon footprint. The key to mastering the use of a metal shearing machine lies in continuous learning and adaptation to new technologies. Regular workshops, attending industry exhibitions, and networking with other professionals can provide insights into the latest trends and innovations in metal shearing technology, keeping you at the forefront of the industry. In conclusion, the selection and operation of a metal shearing machine are critical decisions that can transform your manufacturing capabilities. By investing in quality machinery, prioritizing expert handling, and aligning with trusted manufacturers, you can enhance operational efficiency, ensure precision, and maintain a strong competitive edge.

Real-world experience reflects that using a metal shearing machine not only saves time and reduces labor costs but also contributes to creating a safer workspace. With proper training and safety gear, the risks associated with manual metal cutting are minimized, leading to a reduction in workplace injuries and boosting overall employee morale. For sectors aiming to ensure sustainable practices, selecting eco-friendly metal shearing machines can also align with corporate social responsibility goals. Machines designed with energy-efficient technology reduce energy consumption, leading to decreased operational costs and a lower carbon footprint. The key to mastering the use of a metal shearing machine lies in continuous learning and adaptation to new technologies. Regular workshops, attending industry exhibitions, and networking with other professionals can provide insights into the latest trends and innovations in metal shearing technology, keeping you at the forefront of the industry. In conclusion, the selection and operation of a metal shearing machine are critical decisions that can transform your manufacturing capabilities. By investing in quality machinery, prioritizing expert handling, and aligning with trusted manufacturers, you can enhance operational efficiency, ensure precision, and maintain a strong competitive edge.

Latest News

-

The Rise of Laser Welding: Precision Meets Power in Modern MetalworkNewsAug.06,2025

-

Streamlining Industrial Packaging: The Power of Barrel Production LinesNewsAug.06,2025

-

Revolutionizing Metal Joining: The Power of Automatic Seam Welding MachinesNewsAug.06,2025

-

Powering Industrial Innovation: The Role of Pipe and Tube Machinery in Modern ManufacturingNewsAug.06,2025

-

Exploring the World of Resistance Welding: Equipment, Manufacturers, and Pricing InsightsNewsAug.06,2025

-

Advancing Container Manufacturing: The Role of the Modern Can Welding MachineNewsAug.06,2025

-

Understanding Automatic Seam Welding Machines: A Game Changer in Welding TechnologyNewsJul.18,2025

related products

-

Pneumatic Handle Welding MachineSep . 13, 2024

Pneumatic Handle Welding MachineSep . 13, 2024 -

Fully Automatic Kaiping Production LineOct . 17, 2024

Fully Automatic Kaiping Production LineOct . 17, 2024 -

Fully Automatic Metal Bucket Lifting HeadphonesSep . 14, 2024

Fully Automatic Metal Bucket Lifting HeadphonesSep . 14, 2024