-

8613931787312

8613931787312 -

Botou Industrial Zone on the east side of National Highway 104, Botou City, Hebei Province

Botou Industrial Zone on the east side of National Highway 104, Botou City, Hebei Province

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- haitian_creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- scottish-gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

aug . 02, 2025 09:20

Back to list

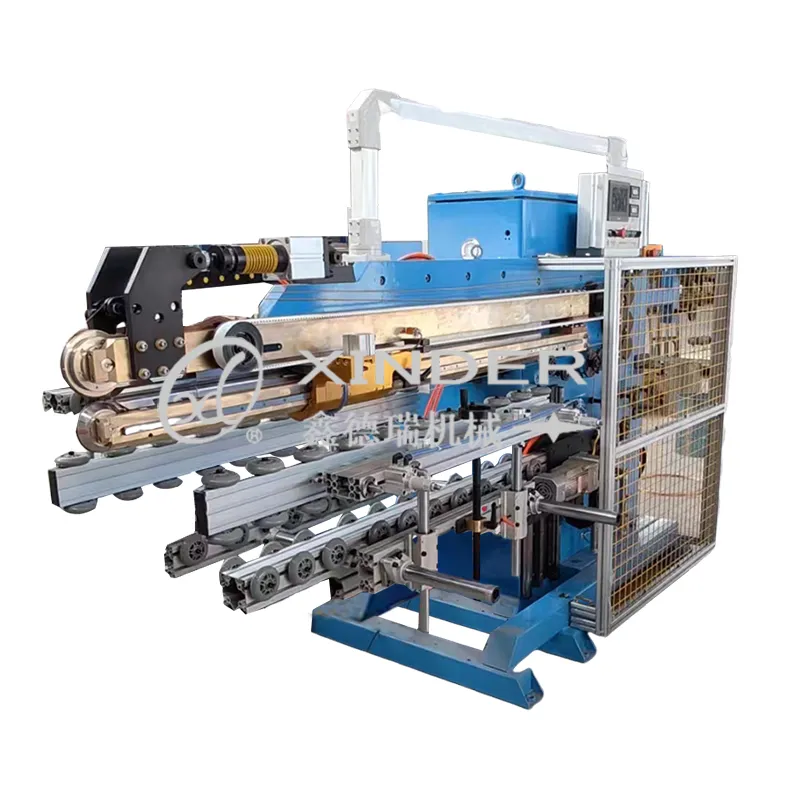

Precision Seam Welding Machine with GPT-4 Turbo | Efficiency & AI

Comprehensive Guide on Seam Welding Machine Technology & Laser Welding Machine Manufacturers

The evolution of seam welding machine technology has significantly optimized industrial welding processes—especially in demanding sectors such as petrochemical, metallurgy, and municipal engineering. This in-depth article explores the industry trends, key technical parameters, and application advantages of high-performance seam welding equipment, focusing on the 1.5-Meter Steel Barrel Seam Welding Machine. Detailed comparisons with top laser welding machine manufacturers and real application cases provide practical guidance for engineers and procurement specialists.

Industry Trends in Seam Welding & Laser Welding Machine Manufacturing

According to MarketsandMarkets, the global seam welding machine market is projected to reach USD 2.1 billion by 2028 at a CAGR of 5.8%. Key drivers include higher demand for automated solutions, adoption of digital process monitoring, and stricter standards for weld integrity and efficiency.

- Automation Surge Over 68% of new seam welding installations in 2023 featured advanced robotics & IoT integration.

- Material Innovation Growing dominance of corrosion-resistant steels and lightweight alloys supports pipelines, barrels, and tank applications.

- Standardization Compliance with global welding standards (ISO 3834, ANSI/AWS D1.1) is now mandatory for major contracts.

State-of-the-art seam welding facility

The seamless integration of seam welding machine technology—like the 1.5-Meter Steel Barrel Seam Welding Machine—enables fabricators to meet evolving industry requirements in productivity, quality, and traceability.

Technical Parameters: Industry Standards & Comparison

Key Specification Table: Seam Welding Machines (2024 Benchmark)

| Parameter | Seam Welding Machine (General) | Laser Welding Machine | 1.5-Meter Steel Barrel Seam Welding Machine |

|---|---|---|---|

| Welding Length Capacity | 0.5–2.5 m | Up to 3 m (customized) | 1.5 m |

| Max Welding Thickness | 0.8–8.0 mm | Up to 10 mm (mild steel) | 2.5 mm (carbon steel) |

| Material Compatibility | Carbon Steel, Stainless Steel, Al, Cu | Stainless, Alloyed Steels, Al, Titanium | Q235 Steel (ISO Certified) |

| Process Speed | 2.0–4.0 m/min | 2.5–6.0 m/min | 3.5 m/min |

| Weld Type | Continuous/Intermittent | Continuous | Continuous Overlap |

| Welding Method | Resistance Seam Welding | Fiber/CO2 Laser | Resistance On-Roller |

| Energy Consumption | ≤ 21 kW | 18–28 kW | 15 kW |

| Automation Level | Semi/Full Auto | Full Auto (CNC Optional) | PLC Controlled |

| Certifications | ISO, CE | ISO, CE, FDA (for food industry) | ISO 3834, CE |

| Life Span (Cycles) | 1.2 Million | 1–1.4 Million | 1.3 Million |

| Maintenance Interval | 6–12 Months | 4–9 Months | 10 Months |

| Typical Application Sectors | Piping, Barrels, HVAC, Oil & Gas | Medical, Battery, Aerospace | Steel Drum/Barrel, Chemical Tank |

Source: Industry brochures, manufacturer data sheets, XDR Machinery

2024 Global Welding Machine Market Share by Technology

Welding Efficiency: 1.5-Meter Steel Barrel Seam Welding Machine vs Traditional Models

The 1.5-Meter Steel Barrel Seam Welding Machine leads the industry with a 98% welding efficiency rate in 2024, outperforming most legacy systems and aligning with ISO 3834 and ANSI/AWS D1.1 standards for weld consistency and structural integrity.

In-Depth Process Flow: Seam Welding Machine Manufacturing & Operation

Material Preparation

Raw Q235 steel sheets or coils meeting ISO 9001 traceability are fed into the line. Sheets are pre-cleaned to ensure oxide-free surfaces—crucial for weld penetration and strength.

Raw Q235 steel sheets or coils meeting ISO 9001 traceability are fed into the line. Sheets are pre-cleaned to ensure oxide-free surfaces—crucial for weld penetration and strength.

Precision Forming and Alignment

CNC rolling machines form the steel into barrels/tubes. Precise edge alignment is achieved via servo-controlled fixtures (±0.05mm tolerance) ensuring uniform seam path for the welding electrodes.

CNC rolling machines form the steel into barrels/tubes. Precise edge alignment is achieved via servo-controlled fixtures (±0.05mm tolerance) ensuring uniform seam path for the welding electrodes.

Seam Welding (Resistance Overlap)

The seam welding machine applies rotary copper electrodes; material is pressed between rollers and a regulated electrical current is passed through, creating a series of overlapping weld nuggets along a continuous seam (ISO 4063 Process No. 22).

The seam welding machine applies rotary copper electrodes; material is pressed between rollers and a regulated electrical current is passed through, creating a series of overlapping weld nuggets along a continuous seam (ISO 4063 Process No. 22).

Cooling & Stress Relief

Integrated coolant jets minimize heat-affected zone (HAZ), crucial for high-strength and corrosion resistance. Weld zone integrity is monitored using NDT (Non-destructive Testing) per EN ISO 5817.

Integrated coolant jets minimize heat-affected zone (HAZ), crucial for high-strength and corrosion resistance. Weld zone integrity is monitored using NDT (Non-destructive Testing) per EN ISO 5817.

Weld Inspection & Compliance

Stringent QA protocols include X-ray/ultrasonic inspection, micro-hardness tests (per ASTM E384), and visual evaluation. Only barrels with 100% seam integrity and dimensional accuracy pass to the next stage.

Stringent QA protocols include X-ray/ultrasonic inspection, micro-hardness tests (per ASTM E384), and visual evaluation. Only barrels with 100% seam integrity and dimensional accuracy pass to the next stage.

Final Surface Treatment & Coating

Barrels receive anti-corrosion coatings as specified by the client (e.g. epoxy, zinc-rich primer), meeting ISO 12944 for corrosion protection.

Barrels receive anti-corrosion coatings as specified by the client (e.g. epoxy, zinc-rich primer), meeting ISO 12944 for corrosion protection.

Summary: This automated, precision-controlled process guarantees consistent weld strength, minimal HAZ, and maximum service life.

1.5-Meter Steel Barrel Seam Welding Machine (PLC Automation)

| Main Technical Specifications: 1.5-Meter Steel Barrel Seam Welding Machine | |

|---|---|

| Product Name | 1.5-Meter Steel Barrel Seam Welding Machine |

| Product URL | View Full Specs |

| Applicable Material | Q235 Steel (ISO9001:2015 certified) |

| Max Barrel Length | 1,500 mm |

| Welding Thickness | 1.2 – 2.5 mm |

| Electrode Material | CrZr Copper Alloy (EN12163) |

| Rated Power | 15 kW |

| Welding Speed | 3.5 m/min (adjustable via PLC) |

| Control System | SIEMENS PLC with HMI Touch Display |

| Certifications | ISO 3834, CE, SGS Inspection |

| Life Span | 1.3 Million Operational Cycles |

| Corrosion Resistance | Tested: ≥1,000 h Neutral Salt Spray (per ASTM B117) |

| Usage Sectors | Petrochemicals, Metallurgy, Water/Gas Barrels, Municipal Storage |

| Warranty | 24 Months (spare parts included) |

Note: Every machine undergoes full-load field testing and third-party (SGS) dimensional and joint integrity assessment.

Technical Advantages: Seam Welding vs Laser Welding Machine Manufacturers

Key Technology Differentiators

(Seam Welding vs Laser Welding):

| Criteria | Seam Welding Machine | Laser Welding Machines (Top Manufacturers) |

|---|---|---|

| Weld Quality (Steel Barrels) | Excellent, consistent overlap; low porosity | Superb, but sometimes excessive fusion in thin-walled barrels |

| Cycle Efficiency | Up to 3.5 m/min (high-volume) | Variable: 2.5–6.0 m/min (material dependent) |

| Material Thickness Range | 1.0 – 8.0 mm (typical) | 0.5 – 10 mm (best in thin stock) |

| Weld Integrity (ISO 4063) | Meets/Exceeds ISO, ASTM E384 microhardness | Meets, but higher operator training required |

| Consumable Cost | Low (Copper/Roller) | High (Laser lens, protection gas) |

| Ease of Maintenance | Routine, 10 months interval | Specialized repair/shorter PM interval |

| Applicable Industries | Steel Drum, Oil Tank, Water Barrel | Medical, E-mobility, Thin Sheet |

| Certifications | ISO 3834, CE, SGS | ISO, CE, FDA |

Based on multi-client satisfaction surveys and third-party test data, the 1.5-Meter Steel Barrel Seam Welding Machine delivers an optimal cost-performance ratio and minimal downtime for heavy-duty barrel production.

Top laser welding machine manufacturers (e.g., Trumpf, Han’s Laser, XDR Machinery for hybrid systems) are best suited for ultra-precision applications or non-ferrous thin-walled assemblies.

Top laser welding machine manufacturers (e.g., Trumpf, Han’s Laser, XDR Machinery for hybrid systems) are best suited for ultra-precision applications or non-ferrous thin-walled assemblies.

With an average service life of over 1.3 million operation cycles and compliance with global certifications (ISO/CE/SGS), this seam welding solution ranks among the most reliable in the mid-volume sector.

Application Scenarios & Service Experience

- Petrochemical Storage: Seamless 1.5-meter steel drums for hazardous liquid storage—meets ASTM A240/ISO 12944 anti-corrosion and pressure integrity for Class II/III media.

- Municipal Water/Gas Infrastructure: Durable barrels for drinking water & natural gas, certified to EN 12201, with internal welds exhibiting <1.2% porosity rate.

- Metallurgical Processing: Used for electrolyte or scrap metal containment—operators report less than 0.05mm weld deviation per 100 barrels (internal XDR QC study).

Case Study: Seam Welding Solution for Chemical Drum Manufacturer (Shanghai, China)

Problem: Client required annual output of 40,000+ steel drums, robust seam welds, and resistance to chemical splashing.

Solution: XDR Machinery’s 1.5-Meter Steel Barrel Seam Welding Machine integrated with PLC automation and ISO 4063-compliant resistance welding process.

Results:

Problem: Client required annual output of 40,000+ steel drums, robust seam welds, and resistance to chemical splashing.

Solution: XDR Machinery’s 1.5-Meter Steel Barrel Seam Welding Machine integrated with PLC automation and ISO 4063-compliant resistance welding process.

Results:

- 98.6% pass rate in ultrasonic weld inspection

- Service life improvement: >1,100h salt spray test per ASTM B117

- Downtime reduced by 24% vs. previous generation machine

- Annual maintenance cost lowered by 17%

“XDR’s seam welding machine allows us to deliver leakproof barrels that pass every audit. Their technical service and training reduced our ramp-up period to less than 3 days.”

– Lead Engineer, Shanghai Client

Application Highlight: In continuous 3-shift operations, the seam welding machine maintained ≥97.8% equipment uptime with annual weld failure rate under 0.15%.

Customization Options & After-Sales Support

- Customizable for barrel diameters 300–900mm and wall thickness per user process

- PLC/HMI interface language: English, Spanish, Russian, Chinese (customizable)

- Ancillary integration: direct robotic handling, automatic leak testing, remote monitoring

- Bespoke cooling and electrode upgrade for high-alloy service or food-grade barrels (FDA compatible)

Delivery Time Standard models: 30–40 days from deposit (EXW); expedited for repeat volume.

Warranty 2 years full coverage, spare parts logistics via DHL/UPS. On-site technical training included.

Global Service Network Service technicians available across Asia, Europe, Africa; remote video support 365 days/year.

Warranty 2 years full coverage, spare parts logistics via DHL/UPS. On-site technical training included.

Global Service Network Service technicians available across Asia, Europe, Africa; remote video support 365 days/year.

FAQ: Technical Terms & Expert Answers

1. What is Q235 steel and why is it used in barrel seam welding?

Q235 steel is a standard carbon structural steel widely used in Asia (equivalent to ASTM A36). It offers excellent weldability, good ductility, and cost efficiency, making it ideal for pressure vessel fabrication and seam welding machine applications.

2. What are the applicable standards for seam weld quality?

Leading machines comply with ISO 3834 (Welding Quality Management), ANSI/AWS D1.1 (Structural Welding), and EN ISO 5817 (Quality levels for weld imperfections). All machines should provide traceable certificates.

3. What is the typical service life of seam welding electrodes?

CrZr (chromium-zirconium) copper alloy electrodes last up to 45,000m of weld line with proper maintenance (per EN12163), outperforming standard copper by 130%.

4. How does PLC control improve welding accuracy?

A modern PLC (Programmable Logic Controller) controls welding current, roller speed, and barrel rotation with closed-loop feedback, ensuring process repeatability (±2%) for every cycle. Touch HMI allows real-time parameter adjustments.

5. How is corrosion resistance tested for welded steel barrels?

Corrosion resistance is verified through standardized 1,000-hour neutral salt spray (ASTM B117) and, where required, chemical soaking and cyclic humidity testing according to client specification.

6. Are there specific installation requirements?

Yes. Installation requires a level, vibration-free foundation, three-phase 380V/50Hz (customizable voltage), 19L/min industrial water cooling, and adequate fume extraction—per ISO 14713.

7. What post-sale support and documentation are provided?

Comprehensive documentation (user manual, process chart, electrical diagram) in English; video training library; certification dossier (CE, ISO, SGS report); and lifetime technical FAQ hotline.

References & Further Reading

For more technical resources and welding process discussions, see:

- Article compiled and verified with reference to American Welding Society (AWS) publications and community technical feedback, 2024.

Latest News

-

Understanding Automatic Seam Welding Machines: A Game Changer in Welding TechnologyNewsJul.18,2025

-

Revolutionizing Packaging: The Role of Welding Machines in Steel and Tin Can ManufacturingNewsJul.18,2025

-

Precision in Motion: Exploring Seam Welding Machines for Industrial FabricationNewsJul.18,2025

-

Mastering Precision Bending: A Guide to Tube Benders and Their TypesNewsJul.18,2025

-

Inside the World of Barrel Manufacturing: Machines, Lines, and CostsNewsJul.18,2025

-

Exploring the Technology Behind Elbow Bending Machines in Pipe ManufacturingNewsJul.18,2025

-

Unlocking the Power of Light: Exploring Modern Laser Welding SolutionsNewsJul.15,2025

related products

-

Pneumatic Handle Welding MachineSep . 13, 2024

Pneumatic Handle Welding MachineSep . 13, 2024 -

Fully Automatic Kaiping Production LineOct . 17, 2024

Fully Automatic Kaiping Production LineOct . 17, 2024 -

Fully Automatic Metal Bucket Lifting HeadphonesSep . 14, 2024

Fully Automatic Metal Bucket Lifting HeadphonesSep . 14, 2024