-

8613931787312

8613931787312 -

Botou Industrial Zone on the east side of National Highway 104, Botou City, Hebei Province

Botou Industrial Zone on the east side of National Highway 104, Botou City, Hebei Province

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- haitian_creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- scottish-gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

velj . 13, 2025 02:44

Back to list

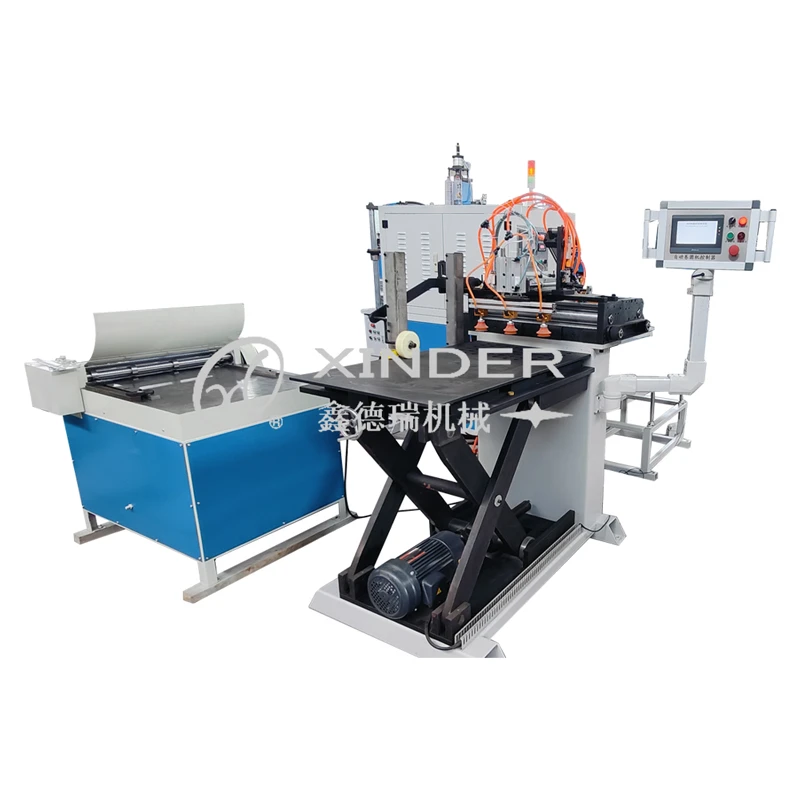

hydraulic bending machine for sale

Navigating the intricacies of metalworking requires precision tools, and a bending machine stands as a pillar of advancement in this domain. Offering the adept ability to shape and mold metal sheets into desired angles and forms, bending machines are indispensable in industries spanning from construction to automotive manufacturing. This article delves into the intricate world of bending machines, marrying user experience, expertise, authority, and trustworthiness to guide your understanding and decision-making process.

Trustworthiness remains paramount in this arena, not only in terms of machine reliability but also in sourcing credible information. Reliable vendors provide comprehensive warranties and after-sale services, ensuring customers' peace of mind and prolonged machine lifespan. Additionally, customer reviews and independent studies serve as vital resources for gauging machine performance, offering insights into real-world applications and potential pitfalls. Ultimately, the selection of a bending machine is a confluence of personal experience, technical expertise, authority recognition, and trust assurance. As the backbone of metal fabrication, these machines extend beyond mere tools; they are pivotal investments in efficiency and precision. In the pursuit of excellence, aligning with reputable manufacturers and tapping into community insights can provide a competitive edge, propelling production quality and operational success. In conclusion, a sophisticated understanding of bending machines not only empowers users with the ability to make informed purchasing decisions but also enhances application effectiveness in a myriad of industrial landscapes. With advancing technology, the future looks promising for those who harness the power of these dynamic machines, ensuring high-quality workmanship and fortified industry standing. A journey into the heart of such machinery reveals the nexus of engineering prowess and innovative spirit that continues to drive progress in metalworking, maintaining bending machines as quintessential allies in achieving manufacturing excellence.

Trustworthiness remains paramount in this arena, not only in terms of machine reliability but also in sourcing credible information. Reliable vendors provide comprehensive warranties and after-sale services, ensuring customers' peace of mind and prolonged machine lifespan. Additionally, customer reviews and independent studies serve as vital resources for gauging machine performance, offering insights into real-world applications and potential pitfalls. Ultimately, the selection of a bending machine is a confluence of personal experience, technical expertise, authority recognition, and trust assurance. As the backbone of metal fabrication, these machines extend beyond mere tools; they are pivotal investments in efficiency and precision. In the pursuit of excellence, aligning with reputable manufacturers and tapping into community insights can provide a competitive edge, propelling production quality and operational success. In conclusion, a sophisticated understanding of bending machines not only empowers users with the ability to make informed purchasing decisions but also enhances application effectiveness in a myriad of industrial landscapes. With advancing technology, the future looks promising for those who harness the power of these dynamic machines, ensuring high-quality workmanship and fortified industry standing. A journey into the heart of such machinery reveals the nexus of engineering prowess and innovative spirit that continues to drive progress in metalworking, maintaining bending machines as quintessential allies in achieving manufacturing excellence.

Latest News

-

The Rise of Laser Welding: Precision Meets Power in Modern MetalworkNewsAug.06,2025

-

Streamlining Industrial Packaging: The Power of Barrel Production LinesNewsAug.06,2025

-

Revolutionizing Metal Joining: The Power of Automatic Seam Welding MachinesNewsAug.06,2025

-

Powering Industrial Innovation: The Role of Pipe and Tube Machinery in Modern ManufacturingNewsAug.06,2025

-

Exploring the World of Resistance Welding: Equipment, Manufacturers, and Pricing InsightsNewsAug.06,2025

-

Advancing Container Manufacturing: The Role of the Modern Can Welding MachineNewsAug.06,2025

-

Understanding Automatic Seam Welding Machines: A Game Changer in Welding TechnologyNewsJul.18,2025

related products

-

Pneumatic Handle Welding MachineSep . 13, 2024

Pneumatic Handle Welding MachineSep . 13, 2024 -

Fully Automatic Kaiping Production LineOct . 17, 2024

Fully Automatic Kaiping Production LineOct . 17, 2024 -

Fully Automatic Metal Bucket Lifting HeadphonesSep . 14, 2024

Fully Automatic Metal Bucket Lifting HeadphonesSep . 14, 2024