-

8613931787312

8613931787312 -

Botou Industrial Zone on the east side of National Highway 104, Botou City, Hebei Province

Botou Industrial Zone on the east side of National Highway 104, Botou City, Hebei Province

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- haitian_creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- scottish-gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

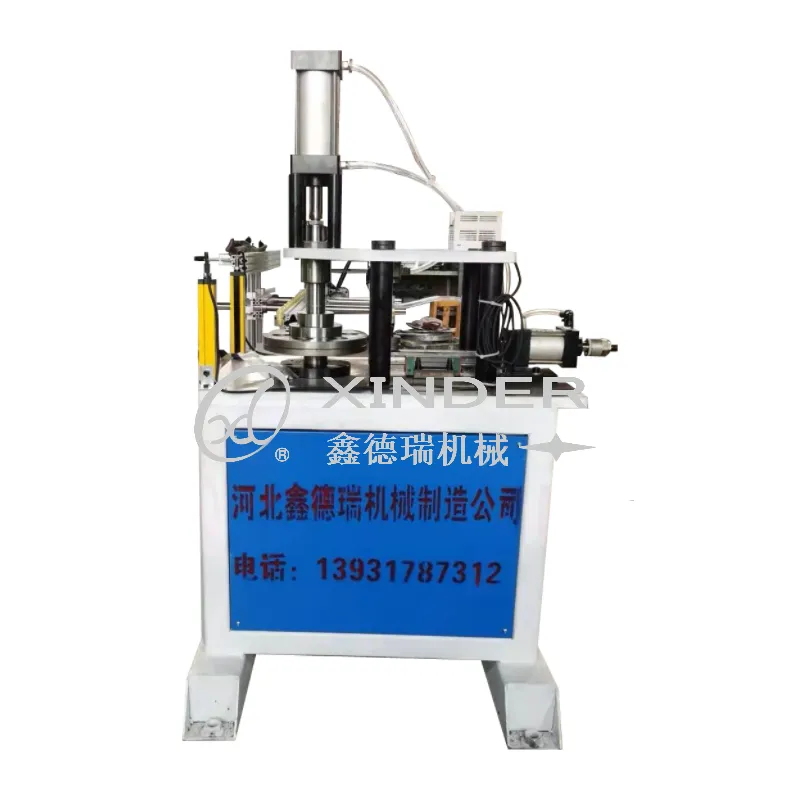

Affordable Bending Press Machine Price High Precision & Durability

- Market Trends & Data Impact on Bending Press Machine Prices

- Technical Superiority of Modern Press Bending Machines

- Manufacturer Comparison: Price vs. Performance

- Custom Solutions for Unique Industrial Needs

- Application Case Studies Across Industries

- Cost-Saving Strategies for Procurement

- Future Outlook: Bending Press Machine Price Dynamics

(bending press machine price)

Market Trends & Data Impact on Bending Press Machine Prices

The global demand for press bending machines has surged by 12% annually since 2020, driven by automation in metal fabrication. A 2023 industry report highlights that the average bending press machine price

ranges between $28,000 and $85,000, influenced by tonnage (20T to 500T) and automation levels. Emerging markets in Asia-Pacific account for 43% of sales, with hydraulic systems dominating 68% of installations due to cost efficiency.

Technical Superiority of Modern Press Bending Machines

Advanced models integrate AI-powered precision controls, reducing material waste by up to 22%. For instance, hand press sheet bending machines now achieve ±0.1mm accuracy, critical for aerospace components. Energy-efficient variants cut power consumption by 35% compared to legacy systems, while servo-electric options eliminate hydraulic fluid costs entirely.

Manufacturer Comparison: Price vs. Performance

| Brand | Model | Capacity | Price Range | ROI (Months) |

|---|---|---|---|---|

| Company A | BP-500H | 300T | $72,000 | 18 |

| Company B | FlexBend Pro | 200T | $54,000 | 14 |

| Company C | EcoPress Lite | 150T | $38,500 | 22 |

Custom Solutions for Unique Industrial Needs

Specialized press bending machine configurations now address niche requirements:

- High-volume automotive lines: 12-second cycle times

- Shipbuilding-grade machines: 8m bending length capacity

- Micro-bending units: 0.05mm thickness tolerance

Application Case Studies Across Industries

A German auto manufacturer reduced chassis production costs by 19% using hand press sheet bending machines with laser-guided alignment. Conversely, a UAE construction firm achieved 98% accuracy in structural steel bending via 500T hydraulic presses, slashing rework costs by $220,000 annually.

Cost-Saving Strategies for Procurement

Leasing options now cover 73% of mid-tier press bending machine price points, with pay-per-cycle models gaining traction. Bulk purchases (5+ units) attract 12-18% discounts, while certified refurbished machines deliver 80% performance at 45% cost.

Future Outlook: Bending Press Machine Price Dynamics

With raw material costs projected to drop 8% by 2025, bending press machine prices may decline 4-6% for standard models. However, smart machines with IoT capabilities will command 25% premiums, reshaping ROI calculations for metalworking enterprises globally.

(bending press machine price)

FAQS on bending press machine price

Q: What factors influence the bending press machine price?

A: The bending press machine price depends on tonnage capacity, automation level, brand reputation, and material compatibility. Higher-tonnage or CNC-enabled models typically cost more than manual variants. Customization and regional market demand also affect pricing.

Q: How does a hand press sheet bending machine price compare to hydraulic models?

A: Hand press sheet bending machine prices are generally lower due to manual operation and simpler designs. Hydraulic models cost more but offer higher precision and efficiency for industrial use. Budget and production scale determine the ideal choice.

Q: Are used press bending machines cost-effective?

A: Used press bending machines can save 30-50% compared to new units, ideal for small workshops. However, inspect maintenance history and wear to avoid hidden costs. Ensure spare parts are available for older models.

Q: What is the average price range for industrial bending press machines?

A: Industrial bending press machines range from $10,000 to $100,000+, depending on specifications. Semi-automatic models start around $15,000, while CNC-driven systems exceed $50,000. Tonnage and additional features significantly impact costs.

Q: Why do prices vary among hand press sheet bending machine suppliers?

A: Pricing variations arise from build quality, material durability, and included features like adjustable dies. Brand reputation and after-sales support also contribute. Compare warranties and user reviews to balance cost and reliability.

-

Understanding Automatic Seam Welding Machines: A Game Changer in Welding TechnologyNewsJul.18,2025

-

Revolutionizing Packaging: The Role of Welding Machines in Steel and Tin Can ManufacturingNewsJul.18,2025

-

Precision in Motion: Exploring Seam Welding Machines for Industrial FabricationNewsJul.18,2025

-

Mastering Precision Bending: A Guide to Tube Benders and Their TypesNewsJul.18,2025

-

Inside the World of Barrel Manufacturing: Machines, Lines, and CostsNewsJul.18,2025

-

Exploring the Technology Behind Elbow Bending Machines in Pipe ManufacturingNewsJul.18,2025

-

Unlocking the Power of Light: Exploring Modern Laser Welding SolutionsNewsJul.15,2025

-

Pneumatic Handle Welding MachineSep . 13, 2024

Pneumatic Handle Welding MachineSep . 13, 2024 -

Fully Automatic Kaiping Production LineOct . 17, 2024

Fully Automatic Kaiping Production LineOct . 17, 2024 -

Fully Automatic Metal Bucket Lifting HeadphonesSep . 14, 2024

Fully Automatic Metal Bucket Lifting HeadphonesSep . 14, 2024