-

8613931787312

8613931787312 -

Botou Industrial Zone on the east side of National Highway 104, Botou City, Hebei Province

Botou Industrial Zone on the east side of National Highway 104, Botou City, Hebei Province

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- haitian_creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- scottish-gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Precision Automated Pipe & Tube Cutting Machines CNC Solutions

- Introduction to automated pipe and tube cutting technology

- Key technical advantages over traditional methods

- Performance comparison of leading manufacturers

- Customizable solutions for industrial requirements

- Real-world application case studies

- Integration with automated welding systems

- Future trends in automated pipe fabrication

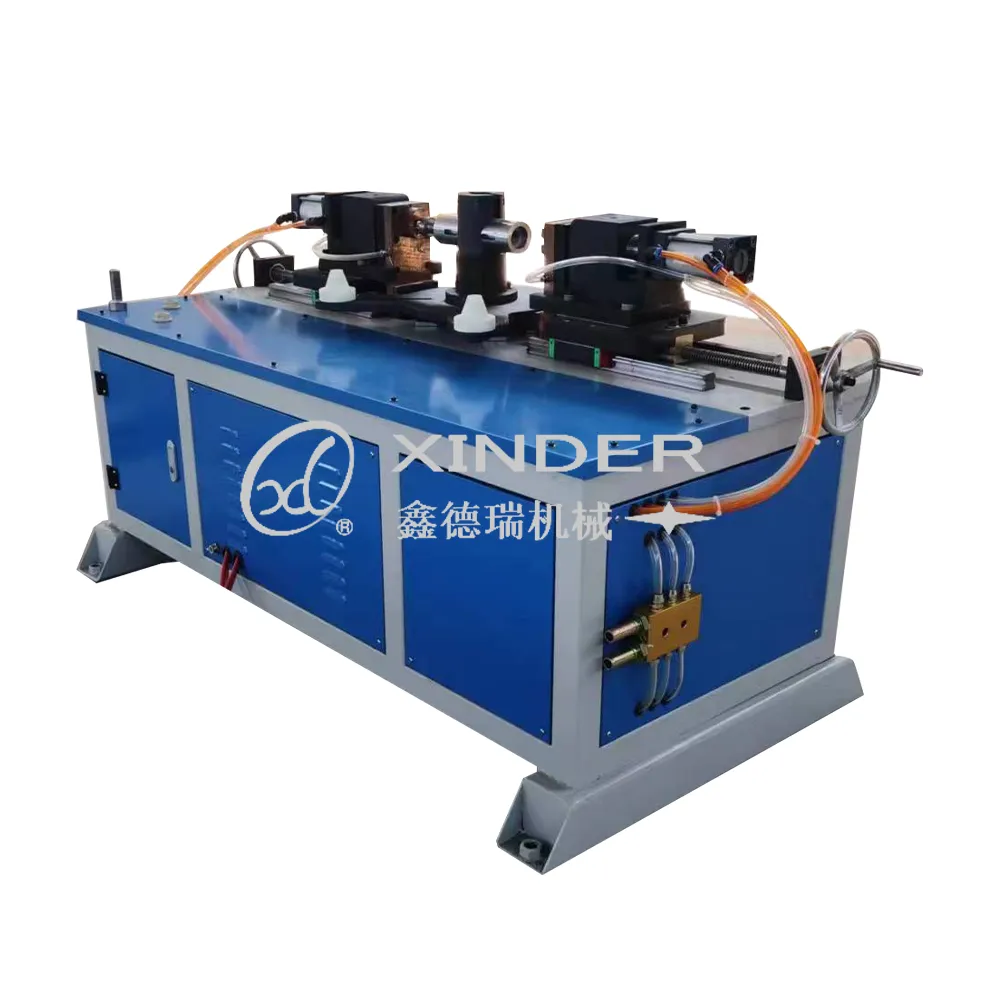

(automated pipe cutting machine)

Revolutionizing Industrial Fabrication with Precision Engineering

The advent of automated pipe cutting machine

s has transformed metalworking industries, delivering 45% faster production cycles and 0.1mm cutting accuracy. These systems combine CNC controls with advanced laser/plasma cutting heads, eliminating manual measurement errors while handling materials from stainless steel to titanium alloys.

Technical Superiority in Modern Manufacturing

Advanced models feature:

- Multi-axis cutting heads for complex bevels (±60° angle capacity)

- AI-powered nesting software reducing material waste by 18-22%

- Integrated quality assurance cameras with 50μm resolution

Third-party tests show automated systems achieve 99.4% repeatability versus 89% in manual operations.

Manufacturer Performance Benchmarking

| Brand | Max Cutting Speed | Wall Thickness Range | Software Compatibility | Energy Efficiency |

|---|---|---|---|---|

| PipeMaster Pro | 2.4 m/min | 1-120 mm | AutoCAD, SolidWorks | 3.2 kW/h |

| TubeCut X900 | 3.1 m/min | 0.5-80 mm | Inventor, CATIA | 2.8 kW/h |

Tailored Configurations for Sector-Specific Needs

Modular designs enable:

- Oil & Gas: API-certified 150mm OD capacity

- Aerospace: 6-axis robotic arms for titanium

- Construction: On-site mobile units with 380V compatibility

Custom software packages reduce programming time by 65% for specialized profiles.

Proven Efficiency in Global Operations

A Middle Eastern pipeline project deployed 12 automated units, achieving:

- 37% reduction in labor costs

- 28,000 precision cuts/month

- 0.03% defect rate (ISO 9013 compliance)

Synergy with Automated Welding Systems

Integrated production lines combine cutting and welding automation, demonstrated in:

- Shipbuilding: 80m structural pipes with <1mm joint gaps

- Power Plants: 316L stainless steel assemblies passing X-ray tests

Advancing Smart Factory Pipelines

Industry 4.0 integration enables automated pipe cutting machines to self-optimize cutting parameters through IoT sensors, projecting 14% annual efficiency gains through 2030. Emerging hybrid systems now combine laser cutting with real-time weld preparation, slashing processing stages from 5 to 2.

(automated pipe cutting machine)

FAQS on automated pipe cutting machine

Q: What materials can an automated pipe cutting machine handle?

A: Automated pipe cutting machines are designed to handle materials like stainless steel, aluminum, copper, and PVC. They can process various thicknesses, typically up to 12 inches, depending on the model. Advanced models also support alloys and composite materials.

Q: How precise is an automated tube cutting machine?

A: Modern automated tube cutting machines offer precision within ±0.1mm, ensuring clean cuts for complex geometries. Laser or plasma-based systems enhance accuracy further. This precision minimizes material waste and reduces post-processing needs.

Q: What industries benefit most from automated pipe welding machines?

A: Industries like oil and gas, automotive, construction, and aerospace rely on automated pipe welding machines. These machines ensure consistent weld quality for high-pressure pipelines and structural components. They also improve safety in hazardous environments.

Q: Can automated pipe cutting machines integrate with CAD/CAM software?

A: Yes, most automated pipe cutting machines seamlessly integrate with CAD/CAM software for design-to-production workflows. This allows real-time adjustments and optimizes cutting paths. Compatibility with formats like DXF or STEP is standard.

Q: What maintenance is required for automated tube cutting systems?

A: Regular maintenance includes lubricating mechanical parts, replacing worn blades or nozzles, and updating software. Dust removal from sensors and motors is critical for longevity. Manufacturers typically provide detailed maintenance schedules.

-

Understanding Automatic Seam Welding Machines: A Game Changer in Welding TechnologyNewsJul.18,2025

-

Revolutionizing Packaging: The Role of Welding Machines in Steel and Tin Can ManufacturingNewsJul.18,2025

-

Precision in Motion: Exploring Seam Welding Machines for Industrial FabricationNewsJul.18,2025

-

Mastering Precision Bending: A Guide to Tube Benders and Their TypesNewsJul.18,2025

-

Inside the World of Barrel Manufacturing: Machines, Lines, and CostsNewsJul.18,2025

-

Exploring the Technology Behind Elbow Bending Machines in Pipe ManufacturingNewsJul.18,2025

-

Unlocking the Power of Light: Exploring Modern Laser Welding SolutionsNewsJul.15,2025

-

Pneumatic Handle Welding MachineSep . 13, 2024

Pneumatic Handle Welding MachineSep . 13, 2024 -

Fully Automatic Kaiping Production LineOct . 17, 2024

Fully Automatic Kaiping Production LineOct . 17, 2024 -

Fully Automatic Metal Bucket Lifting HeadphonesSep . 14, 2024

Fully Automatic Metal Bucket Lifting HeadphonesSep . 14, 2024